New OSHA welding rules

If you work with stainless steel or chromium containing products you need to prove you’ve got a fume control solution.

By Tom Jackson

At the end of May any shop, factory or facility that welds, grinds or cuts stainless steel or uses hardfacing alloys that contain chromium or using welding processes on surfaces with chrome plating will come under new Occupational Safety and Health Administration rules.

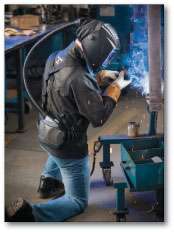

Powered respirators are one alternative when fume extraction equipment is not feasible.

Powered respirators are one alternative when fume extraction equipment is not feasible.The new OSHA Standard for hexavalent chromium requires all employers to have what it calls “engineering controls” in place for employee protection, regardless of whether you employ just one person, or thousands. Failure to comply can subject you to OSHA fines. (Hexavalent chromium is a solid but microscopic particle contained in the fumes generated when welding metals containing chromium. These particles can be inhaled and are thought to cause cancer.)

And while there aren’t a lot of construction applications that call for welding or grinding stainless alloys, the burden of proof is on the employer. If OSHA asks, you must be able to prove to them you have measured your employees’ exposure to hexavalent chromium and your employees exposures are below the designated threshold. If they are not, you must prove you have engineered solutions in place to reduce exposure to acceptable levels.

“The employer’s responsibility is to do the assessments of exposures and then based on that, the regulation tells you all the other things you have to do,” says Doug Dunbar, a certified industrial hygienist for Lincoln Electric. “Once you’ve done the assessment it could be you don’t have to do anything. If you have satisfactorily characterized your exposures and they’re all under the action level, there’s no additional controls needed provided nothing in the workplace changes.”

Although the OSHA regulation doesn’t mandate it, to do the assessments, your best bet would be to hire an industrial hygienist. You can find a local source by checking the website of the American Industrial Hygiene Association (https://www.aiha.org/) or the American Board of Industrial Hygiene (http://www.abih.org/).

“If you have an operation of any significance and you haven’t qualified your exposures, you’re going to want to have this documentation gathered in the right way and presented in a way that’s going to stand up to scrutiny,” Dunbar says. “So it’s probably worth the investment for most people.”

An industrial hygienist can also help you develop the engineered controls OSHA requires that are appropriate to the exposure levels in your operations. In some cases all you may need to do is change a process so that it doesn’t emit as much hexavalent chromium, says Eric Sommers, product specialist, respirator protection for Miller Electric. If that is insufficient or not possible, the next step is to prevent the fumes from getting to the welder,” Sommers says.

One of the best ways to do that is to install a fume extractor. These can be portable units that look like a shop vac you can roll around and set up wherever you’re going to weld. Then there are stationary units with multiple arms that can be set up over fixed welding stations.

If fume extraction equipment is not feasible, you may be able to meet the requirements with a respirator, half mask or full mask, with a NISOH-approved filter that’s designed for hexavalent chromium particulate coming from welding fumes. “You have to select the right respirator and that depends on knowing what your exposure levels are,” Dunbar says.

Welding outdoors presents some unique challenges. “If you’re welding outside and you don’t have an exposure concern, you may not have to do anything,” Dunbar says. “The natural ventilation, wind direction and how the welder positions himself regarding the fume may be enough. But it’s a performance-based standard, and if OSHA says it’s not enough then you have to have a proper solution in place.”

“One of the things that’s important, whether they’re outside or inside, is the fact that they’re trained properly on how to use the equipment and how to position themselves so they don’t receive exposure,” says Deanna Postalwaite, marketing manager for Lincoln Electric Automation. “Even if they have a solution in place it’s important to continue to train all of the employees on the proper use of the equipment and how to position themselves so they’re not at risk of exposure because the positioning and the way they actually weld can put them in danger of being exposed. EW

RESOURCES:

New OSHA 32 page booklet, downloadable for free at:

https://www.osha.gov/sites/default/files/publications/OSHA-3373-hexavalent-chromium.pdf

Highlights of the New Hexavalent Chromium Standard (3M)

http://www.multimedia.3m.com/mws/mediawebserver?66666UuZjcFSLXTtMxMcoXftEVuQEcuZgVs6EVs6E666666–

Frequently asked questions

http://www.solutions.3m.com/wps/portal/3M/en_US/OH-ESHexChrom/Hexavalent_Chromium/Home/FAQ/

Fume extraction equipment:

Lincoln Electric:

https://www.lincolnelectric.com/fume-extraction.asp

Miller Electric:

http://www.millerwelds.com/products/fumeextraction/

Powered respirator:

http://www.millerwelds.com/products/welding_protection/filtration/papr/