“This is where you need most of the pressure and power to operate,” says Ray Gallant, Volvo CE vice president of sales support — Americas. “We’re not generating electricity, and we’re not storing energy.” Instead, a hydraulic accumulator provides the additional power for the lift, assisting the hydraulic pump.

The result, Volvo says, is a system that delivers up to 15 percent lower fuel consumption and 12 percent less CO₂ emissions than a conventional machine. When used in high production applications – especially those within a 90-degree swing – the company indicates the fuel saving payback is approximately two years.

The machine will make its North American debut at Volvo CE’s ConExpo 2020 booth, located at F3432 on the Festival Grounds.

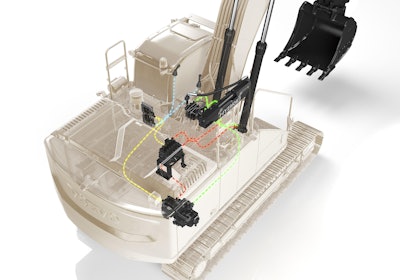

Close-up of the Volvo EC300E Hybrid accumulator.

Close-up of the Volvo EC300E Hybrid accumulator.Consistent energy source

Unlike the energy stored with the swing motion of an excavator, the boom-down motion provides a consistent energy source to charge the 5.2-gallon hydraulic accumulator, Volvo says. The accumulator in turn drives the hydraulic assist motors that help power the hydraulic pump.

“In the downward movement, the weight of the boom, the empty bucket and the gravity pulling it down is very consistent,” Gallant explains to Equipment World. “The speed of the drop is what gives you your flow. This allowed us to downsize the accumulator since a small amount of oil at a high pressure is feeding back into the lift system.” The system, however, works best at boom drops of around 5 feet and over, he adds.

The accumulator is mounted just behind and to the side of the excavator boom. When the boom goes down, the high-pressure oil being used to retard the boom dropping goes into an accumulator instead of being routed back to the tank. The oil is then routed through an assist motor and put back into the cylinders on the upswing.

Gallant says one of the design drivers was keep the accumulator small. “It’s compact, nonintrusive and it doesn’t block visibility,” he says. On the EC300E Hybrid, the accumulator is around 30-inches long and 5 inches wide with guarding adding additional width; larger machines will require larger accumulators.

“It’s all automatically controlled,” Gallant says. “The operator doesn’t have to do anything. He just feels the system working because the engine isn’t lugging out when doing a lift.” An on-dash indicator shows when the system is deployed.

Volvo says the hybrid machine has the same level of controllability and performance as the standard EC300E, including the ability to work in ECO mode and Hybrid mode simultaneously.

Volvo will expand this hybrid hydraulic assist system to other models at a later point. It is not currently available as an aftermarket installation.

Below is Volvo’s video on the system: