Experts say costs are dropping to install smart work-zone systems, thanks to lower prices for gear and greater availability of portable systems.

One of the applications of intelligent traffic systems (ITS), smart work zones are currently best suited for freeways and expressways with higher speeds, multiple lanes and sometimes chaotic traffic.

Prices are dropping for the electronics, computers, and communications equipment used to collect traffic information, process it and then act on it, says Ken E. Johnson, a Minnesota Department of Transportation engineer who specializes in work-zone traffic control.

“The technologies are getting such that it will be less costly to install intelligent work-zone systems,” Johnson says, adding that there are now different and less expensive ways to detect what traffic is doing, from LIDAR (light detection and ranging) to Bluetooth sensors to Doppler systems. “For project managers who are considering using them, the price has dropped quite a bit.”

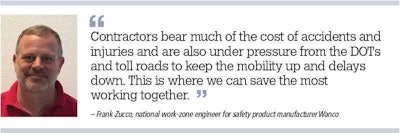

Frank Zucco, national work zone engineer for safety product manufacturer Wanco, agrees. His Colorado-based firm designs, engineers and manufactures portable safety equipment and accessories for traffic management, construction, mining and other industries.

“The costs are coming down for discrete items, but what we’re also finding is that portable ITS is able to replace things that used to be expensive and only possible in fixed installations,” Zucco says.

Information once presented to drivers only through fixed systems can now be displayed on portable ITS message signs placed on the sides of highways, he says.

Fixed-installation systems are much more expensive, involving such things as poles, concrete foundations, power and optic line installation and affiliated construction, Zucco adds.

Portable, full-function ITS trailers can bring significant savings and capabilities not possible with fixed infrastructure systems alone, he says. Though both types of systems are important, the portables are most helpful during construction, events and emergencies, Zucco explains. Portable ITS is easier to set up, costs less and can be moved to the next job.

With portables, Zucco adds, “you can just take a message board and pull it onto the side of the road, press a button for it to go up and you’re done.”

As the technology matured and systems became easier to use, researchers began to document a 40- to 60-percent reduction in rear-end collisions while using queue warning systems, also known as the “stopped traffic ahead” system, Zucco notes.

“The FHWA started really pushing, telling states that ‘we want to see more of this because now we have proof that it improves safety and mobility,’” Zucco says. “We’ve seen a much bigger expansion of ITS just in the past three years.”

How smart zones work

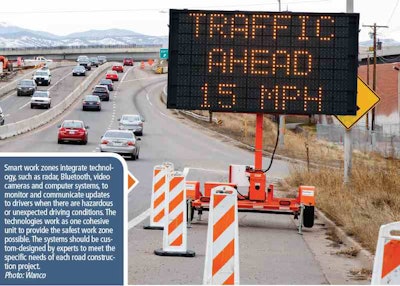

Intelligent work-zone systems detect, calculate and then communicate to drivers what they should do.

“Detection senses what the vehicles and traffic are doing,” Johnson explains. “Algorithms, or computer programs, determine what information is needed for the drivers. And then there’s a communication device of some sort letting the drivers know what they ought to be doing.”

A prime example, he says, is the queue detection warning system. As drivers near work zones, the queue management systems – especially when coupled with traffic information strategies – can alert drivers.

When work-zone traffic drops below a certain speed, the computer either changes the message on a sign or activates the flashing lights on a static sign, Johnson says.

There also are speed management solutions, such as variable speed limit systems, that dynamically manage work-zone traffic based on real-time conditions, including traffic congestion and bad weather. Combining this with automated enforcement can help get drivers to comply with displayed speed limits, according to the Federal Highway Administration’s Center for Accelerating Technology.

Queue and speed management both use a range of technologies for detection.

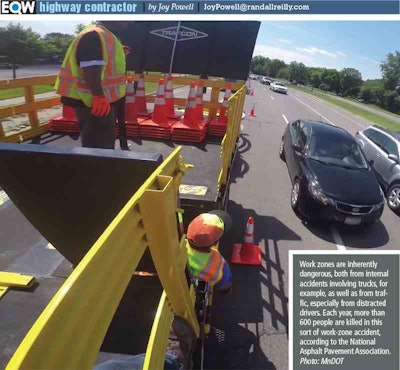

Reducing the costly toll of work-zone accidents

There’s a greater overall savings that comes with reducing the number of accidents and traffic delays as a result of improving work-zone safety, say our experts.

FHWA statistics show there are 500 to 1,000 deaths and more than 25,000 injuries from the estimated 80,000 crashes each year in work zones.

“Contractors bear much of the cost of accidents and injuries and are also under pressure from the DOTs and toll roads to keep the mobility up and delays down,” Zucco says. “This is where we can save the most working together.”

Hildie Devorah Henderson, head of engineering for PDP Associates, a transportation research and technology company, notes that smart work-zone systems improve safety for both travelers and road construction workers. She cites information from the Centers for Disease Control and Prevention (CDC) in Atlanta, which says this occupation has one of the highest fatality rates.

The CDC relies on statistics from the Bureau of Labor Statistics, which reports road-construction worker fatalities:

• From 2003-2015, 1,571 workers lost their lives at road construction sites.

• The number of fatal work-related injuries at road construction sites averaged 121 per year.

• Over the 13 years from 2003-2015, Texas ranked as the state with the most worker deaths at road construction sites (171), followed by Florida (104), Pennsylvania (85), Illinois (69), California (69) and Tennessee (62).

ITS systems offer ways to combat the sudden, often fatal, traffic slowdowns in work zones.

Henderson points to PDF’s quick-linking smart work-zone system called QLynx. It detects and disseminates real-time traffic speed information, including end-of-queue warning, travel time and speed ahead display.

A newer product gaining popularity warns drivers ahead of time to slow down for trucks entering traffic, she says.

Promoting smart work zones and tools for using them

Minnesota transportation officials are trying to spread the word of ITS benefits to project managers.

Minnesota uses several systems, including the active zipper merge (formerly called the dynamic late merge), the queue detection warning system (also known as stopped traffic ahead), dynamic speed displays attached to speed limit signs or advisory speed plaques (which promote more driver adherence to the messages) and travel time systems. The public has overwhelmingly endorsed use of the travel time systems, Johnson says.

Another intelligent work-zone system used in Minnesota is an electronic version of the “workers present” speed zone limit. This typically is used on projects that cover longer distances and have workers right next to traffic lanes.

“Each state does speed limits differently, but in Minnesota we have a law for putting up a workers-present speed zone limit in certain conditions. It should only be up there and active when workers are present,” Johnson says. “We have had issues in the past when the workers-present speed limit sign is left up when workers leave the project.”

Workers use a mobile digital device to program the sign to display the workers-present speed limit. In the past, a tablet served as the mobile device, but MnDOT experts are working with vendors to develop systems that wouldn’t require operation by an electronic device.

“We could have devices in the work vehicles that would update the signs based on the location of the work vehicle,” Johnson says of this system for a workers-present speed limit.

In long-distance work zones, an electronic work zone speed limit assembly is put up every mile, displaying either a regular speed limit or a workers-present speed limit. The speed limit is modified to the workers-present speed limit for those areas of the work zone where workers are present. Not all states use this technology, which both detects and communicates.

Johnson is keeping tabs on technology. Soon, systems may automatically detect sensor-wearing workers within a certain proximity.

“We haven’t seen that system yet,” Johnson says. “With the systems that we’ve seen used in our state, someone controls it with an iPad or an electronic device. But as we move into the future, the sensors are getting less expensive; the computers are getting smaller and much easier to implement. There are a lot of things that are going to make our intelligent work-zone systems more effective.”

One caveat: “A lot of this is not off the shelf,” Johnson says. “You need to have some expertise in putting everything together for it to work.”

MnDOT, which has been using smart work zones for at least 15 years, is updating its toolbox for project managers and contractors using intelligent work zones. That toolbox is available to anyone at https://bit.ly/2JvjRmM.

Planning early for smart work zones

While MnDOT has developed tools to encourage project managers to use intelligent work zones in more applications, there’s a new push to get them to think about this early in their planning.

Usually, temporary traffic control and design plans are thought of last in the process. But project managers should include them in the scoping phase, envisioning how the system will operate within the work zone, Johnson says.

If you don’t understand what a general cost of the project is going to be at the scoping phase, once you get further down the line, there’s often no funding to add smart work zones, he stresses.

And boiler plate provisions designed to simplify contracts will be available soon, Johnson says. “These will make it easier and more consistent for the application of the smart work zone,” Johnson explains. “They can just pull that as opposed to developing their own.”