The systems range in tank sizes of 200 to 950 gallons and engines of 5 to 25 horsepower for small to mid-size drilling jobs.

Ditch Witch made a series of upgrades to increase the systems’ fluid velocity. Those upgrades include a new wet hopper that has steeper sides and expands the venturi inlet by 60 percent, which also improves mixing performance, the company says. The mixing is further improved by a sloping tank bottom that ensures “all drilling fluid flows through the pump and is thoroughly mixed,” a news release says. Some of the models also have built-in bag rippers to speed up mixing cycles.

Ditch Witch’s fluid management systems include the FT5, FM5X, FM13X and FM25X. All feature a powder-coat finish to hinder rust, chipping and fading.

FM25X

The FM25X is the largest, designed for mid-size jobs and to work with the company’s JT25 drill. It is powered by a 25-horsepower Kubota diesel engine. It comes standard with a 500-gallon tank, and a 950-gallon tank is an available option. The FM25X features a two-tank system that can simultaneously mix fluid and pump mixed fluid for drilling. That eliminates the need to stop drilling for mixing. The FM25X also has a variety of configuration options, including curbside and street side, for easier transport. And it has fuel configurations on both sides of the unit.

FM13X

The FM13X runs on an 11.7-horsepower Honda gasoline engine and can be used with all sizes of HDDs for mid-size jobs, the company says. It, too, is available with 500- or 950-gallon tanks. Its Flomax pump delivers 200 gallons per minute of 42-viscosity drilling fluid. It can yield up to 950 gallons of fluid in 8 minutes.

FM5X, FT5

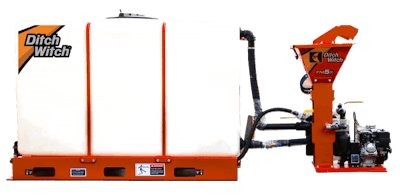

Ditch Witch FM5X

Ditch Witch FM5XThe FM5X and FT5 models are designed for smaller jobs, with each having a 5-horsepower Honda gasoline engine. The FM5X is compatible with Ditch Witch’s JT10 HDD and some applications for the JT20. It has a 300-gallon tank, and its Flomax pump discharges 160 gallons per minute.

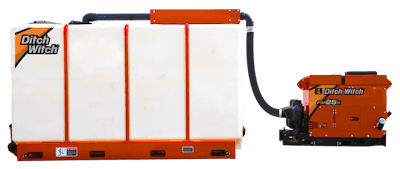

The FT5 has a 200-gallon tank and is designed for small jobs, delivering 18 gallons per minute of flow to the drill. Tanks on both systems are narrow and can be positioned side-by-side with a drill unit on a trailer. The FT5 can also be transported on a small truck.

Ditch Witch FT5

Ditch Witch FT5