A new partnership between Komatsu and Silicon Valley autonomy startup Pronto is bringing rigid-frame dump trucks retrofitted with autonomous technology to North American quarries.

The collaboration leverages Pronto’s autonomous haulage tech to power Komatsu’s newly launched Smart Quarry Autonomous system for quarry-sized haul trucks. The technology can be retrofitted to existing Komatsu haul trucks or be factory fitted on new models.

Through artificial intelligence, cameras, GNSS and a series of sensors, Pronto’s technology enables all-day operation with minimal human input, removing drivers from the immediate quarry environment. Owners will benefit from consistent cycle time, better fuel efficiency and new data analytics from the Smart Quarry platform, Komatsu says.

Aimed at lowering the costs and simplifying autonomy in quarries, Pronto bills its systems as “the most affordable” on the market due to the absence radar or LiDAR and its required equipment.

Pronto says deploying its system can improve quarry productivity by up to 20% by avoiding unplanned maintenance, easing congestion and reducing trucking idling time. The brand-agnostic hardware can be fit onto a fleet in a few weeks.

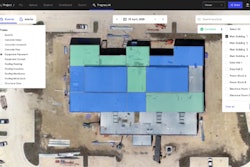

Through an app, Pronto users can access control of their haul trucks, track fleet performance, monitor truck locations and see individual truck metrics.

“Previously, the most advanced autonomy was reserved for the largest mines,” said Anthony Levandowski, CEO of Pronto. “We’re enabling a future of enhanced safety and incredible productivity that is now accessible to quarries of all sizes.”

Pronto recently acquired SafeAI, a company that also retrofits heavy equipment such as dump trucks, pickup trucks and skid steers with autonomous technology.