Liebherr’s new Free Modeling assistance system allows operators of its dozers to create and modify 3D site models from the cab in real time, increasing efficiency and reducing project costs.

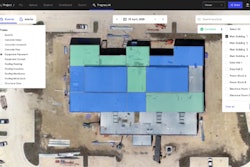

The system integrates GNSS machine control with advanced sensors and real-time data visualization during operation, giving operators the ability to visualize projects in 3D and adjust plans based on current site conditions. This capability drives proactive site management, ensuring projects remain on track and within budget, Liebherr says.

The Free Modeling software is adaptable to a variety of construction projects, from small road repair to a major highway construction project. Liebherr says this flexibility ensures the benefits can be leveraged across a wide range of applications and environments.

The intuitive interface features visualizations and easy-to-understand functions, allowing operators to quickly pick up the technology. Training programs are also available to familiarize operators with the system, emphasizing hands-on experience and practical applications.

Operators can switch between different views, enlarge certain areas and adjust the 3D models with simple gestures on the touchscreen.

The ergonomic design of the machine, user-friendly interface and intuitive and responsive controls all contribute to increased comfort and reduced operator fatigue. Liebherr’s dozers are all equipped with a hydrostatic drive for reduced noise and a smoother ride. To learn more about its latest models, check out this episode of The Dirt: An Overview of Liebherr’s 8th Generation Dozers.

Additional benefits for road construction contractors include:

- Accelerated project timelines: Reduces the amount of time spent on planning and surveying while giving operators the ability to create and modify site models from the machine.

- Improved accuracy: Provides operators with real-time data, which reduces the likelihood of errors due to miscommunication or outdated plans.

- Better collaboration: Data is accessible to all team members, including project managers, engineers, and operators, allowing issues to be addressed quickly.

- Cost reduction: Reduces overall project expenses by minimizing the need for dedicated site surveyors and rework.

- Increased sustainability: Optimizing site operations in real-time contributes to more environmentally friendly practices by improving resource management and reducing waste.

“Embracing these advancements allows construction companies to improve their operations, enhance their competitiveness, and ultimately deliver better results for their clients,” Liebherr says.

[Related Content: When It’s Time to Do Some Real Dirt Moving – The Latest in Dozers]