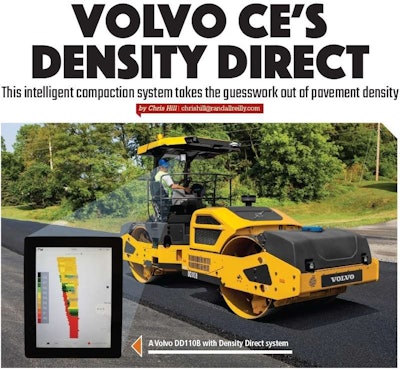

Introduced at the World of Asphalt show this past March, Density Direct’s key differentiation is calculating density of asphalt pavement, rather than the stiffness value, by using the air void content of the pavement.

The research and development of this system goes back 10 years, says Fares Beainy, research engineer for emerging technologies at Volvo. He was at the University of Oklahoma serving in various capacities while fine-tuning the system through a partnership with the university, Volvo and the Federal Highway Administration.

Density Direct uses the same sensor – an accelerometer – as other compaction systems to measure the acceleration of the drum. In adition, it also uses an algorithm that allows the machine to indicate a density calculation. This figure is displayed on an in-cab Android tablet with multi-touch capabilities, like a smart phone or consumer-level tablet. The screen also displays temperature and pass mapping, and the operator can toggle back and forth between them and the density display.

“You cannot measure stiffness in real time in the field,” Beainy said. “Density is easier for the operator to understand. It’s not for quality assurance, but for quality control,” adding that density also is the quality contractors are judged by at the end of a project, rather than stiffness.

What’s striking about the system is its accuracy relative to actual density, which can only truly be measured via a core sample. Beainy says that once the system is calibrated, it can estimate density to within 1.5 percent of a core sample’s actual density.

That calibration is a key process, one that must be done on a test strip, much like contractors have done in the past prior to compaction. Because the Density Direct system stores data from a job, Beainy says the first step is to set up the job on the tablet, including compaction location, the lift, material type and any other pertinent data for tracking the job—a process that is intuitive and user friendly.

To do this, an operator moves the machine on a test strip, turns on the vibration, and then pushes the calibrate button on the display. The test strips initially show up with red dots in the display, indicating no compaction has taken place.

After the operator passes over the test locations once, the test strips change to yellow, then to green when the preset number of passes have been reached. At that point, the operator can choose to end the calibration, selecting that option on the screen, and the system will then set itself up in about 30 seconds for actual compaction.

Just as during the calibration process, the machine display shows red, yellow and green during the compaction process, indicating the proximity of the target compaction level.

From the operator’s perspective the system isn’t just a tool for determining compaction accuracy, it’s also a mechanism for multitasking.

“A lot of times we rely on our quality control guys, but they have 10 other jobs to do while they’re on the road,” says Joseph Petracone, an operator with Massachusetts-based Palmer Paving who helped test the system. “So when you look at the screen and it says ‘OK, here’s what you need for compaction for the minimum or maximum,’ you don’t have to keep relying on someone else around you and you know you’re doing your job properly. It just makes it a little easier as an operator to make sure you hit the whole road consistently.”