Z7 loaders sport new styling

Kawasaki intros first two models of 15-machine lineup

By Tom Jackson

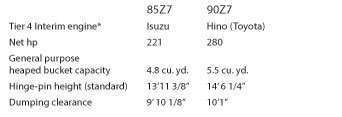

Shipments started this April on the first two models of Kawasaki’s Z7 wheel loader lineup, the 85Z7 and the 90Z7. These will be joined by four additional Z7 machines by the end of this year, with an eventual 15 models in the line.

Kawasaki is adding a new building at its Newnan, Georgia plant to handle Z7 production, which replaces the ZV-2 series.

Kawasaki is adding a new building at its Newnan, Georgia plant to handle Z7 production, which replaces the ZV-2 series.“The Z7 is a dramatically different machine,” says Gary Bell, vice president-general manager, Kawasaki Construction Machinery Corporation of America, noting that both Kawasaki and Hitachi engineers worked on the machine, the result of a joint venture that began in 2008. “Virtually every part is new.” Immediately apparent is the series’ new styling and all-new cab, offering enhanced visibility and cab pressurization.

Both machines offer a package of previously optional equipment as standard, including an integrated backup camera, forward/reverse switch, battery disconnect switch, turn signals with flashers and lifting eyes. Limited slip differential will be standard on the 85ZV models and under.

Kawasaki says the new line up offers lower operating costs and fuel-efficient variable displacement piston pumps. “Kawasaki is a leader in piston pumps in excavators (not sold in North America), but we’ve never used them in our loaders,” Bell says. “They are much more fuel efficient, since they only use energy when the hydraulics are used, in comparison to gear pumps, which run all the time.”

The Z7’s IntelliTech systems help the operator adapt to working conditions, and can be automatic or operator selected. These systems include:

• The patented IntelliDig, which kicks into action as the bucket moves into a pile. “It balances rimpull and hydraulic force,” Bell explains, “metering out power as the bucket comes through the pile.”

The Z7 interior offers four times the cab pressurization than the previous ZV-2 models. The standard rear camera can be operational all the time, only in reverse or turned off. A sliding side console moves to fit operator preferences.

The Z7 interior offers four times the cab pressurization than the previous ZV-2 models. The standard rear camera can be operational all the time, only in reverse or turned off. A sliding side console moves to fit operator preferences.• Simul-Load, which gives operators the ability to both tilt the bucket and raise the loader arms simultaneously while digging, then go to tilt-priority control in the upper range of the lift. Operators can set when in the lift they want the system to switch over to tilt-priority.

• Quick Cycle, used when approaching a truck or dump site while raising a loaded bucket, does not allow a second-to-third gear upshift “until the boom is fully raised,” Bell says.

Quick Specs -- * The first Z7 models will have Isuzu engines on the 85, 95 and 115 models; Hino engines on the 90 and 92 and Cummins engines in the 70 and 80 models.

Quick Specs -- * The first Z7 models will have Isuzu engines on the 85, 95 and 115 models; Hino engines on the 90 and 92 and Cummins engines in the 70 and 80 models.A quick power mode button, located on the side of the left control lever, gives operators a power boost for hill climbing, digging into a pile, or whenever additional rim pull is needed. The machine will stay in the power mode until a transmission change.

Two down shift buttons, located at the top and side of the right control lever, allow down shifting one gear for added rimpull. And a shift hold button holds the transmission in gear when needed.

For more information, go to kawasakiloaders.com/Z7.