But perhaps the biggest reason biodiesel is gaining traction is the fact that its environmental benefits are substantial. That is driving a lot of interest from government and corporate fleets that want to project an environmentally conscious image.

In 2016, refiners produced about 2.9 billion gallons of biodiesel, representing almost 5 percent of the diesel market in the United States. “I’ve been in biodiesel since 2007, and we’ve seen exponential growth,” says Jon Scharingson, executive director of sales and marketing at REG (Renewable Energy Group). “It’s a mainstream fuel at this point and no longer a niche.”

Biodiesel is typically sold to end users as a blend of biodiesel and petroleum-based diesel. The nomenclature includes a capital “B” (for biodiesel) followed by a number that indicates the percentage of biodiesel versus petro-diesel. So B5 is 5 percent biodiesel and 95 percent petro-diesel. B20, a common blend for commercial purposes, is 20 percent biodiesel/80 percent petro-diesel.

Costs

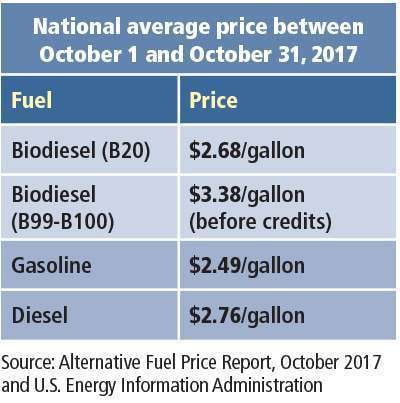

Pure B100 biodiesel by itself is more expensive to make than petro-diesel. But thanks to the Renewable Fuels Act of 2007, credits generated by renewable fuel production brought the price down to $2.68 a gallon for B20 last fall (see chart next page). What’s important to remember is that 80 percent of a B20 blend is diesel, so the price of the biodiesel is actually much lower than diesel. For example, if the credit’s total value was $1.20 a gallon, the B100 price would be $2.18. It’s the diesel that brings the B20 price back up to $2.68, which is still lower than the straight diesel cost of $2.76.

As the chart shows, B20 was actually less expensive than regular petro-diesel. The price equation gets even better for end users when state and/or local tax credits and incentives are factored in. If you are buying fuel in bulk, your provider may also share the incentives and rebates. For a list of the current state tax incentives go here.

“In most cases the $1-per-gallon credit would be represented in the price to the fleet,” says Scharingson. “But it’s not unusual for large fleets, including municipal fleets, with their own fueling sites to blend their own fuel. In that case, the blender files a claim with the federal government to collect the credit, and they can do that once a year to claim everything at once. Even for non-blenders, it’s common for a contract between parties to have language that shares the credit between the person who is eligible for it and the person they’re selling it to.”

Environmental benefits

With the real price of biodiesel below petro-diesel, the other big driver of its use is its environmental benefits.

As the chart below illustrates, B100 and B20 substantially reduce particulate matter, total hydrocarbons and carbon monoxide. Additionally, biodiesel is nontoxic, biodegradable and has none of the aromatics found in traditional diesel, which are considered carcinogenic.

Get the specs

In an engine, biodiesel blends up to B20 perform as well as petro-diesel. And they can be used in most existing diesel engines without modifications. But to avoid possible problems or warranty issues with your engine OEM, make sure the biodiesel conforms to the new industry specs and standards.

The ASTM standard for diesel fuels is ASTM D975. For biodiesel, the spec is ASTM D6751.

Diesel fuel sold in the pipeline and terminal system of the United States must meet the D975 spec and contain no more than 5 percent biodiesel, says David Forester, global product development, Fuel Quality Services. That relatively small quantity of biodiesel seldom has any significant effect on the properties of D975 diesel fuel, except for lubricity improvement, as long as the biodiesel blendstock that makes up that 5 percent meets all the specs of D6751. So normal storage and handling recommendations can be used.

If the diesel fuel contains between 6 and 20 percent biodiesel, it should meet the product specifications of D7467 Diesel Fuel Oil, B6 to B20 blends, which are more rigorous than D975, especially for stability, says Forester. Also, meeting all the specs of D6751, especially residual metals (sodium, potassium, magnesium and calcium) and glycerin/glycerides, becomes increasingly important when blends of 10 to 20 percent biodiesel are purchased and used.

Another industry value to look for is an accreditation known as BQ-9000, a voluntary program that promotes high-quality processes for the manufacturing and blending of the fuel, as established by the National Biodiesel Board Accreditation Program. Any biodiesel you use should adhere to both the ASTM specs and BQ-9000.

Cold weather concerns

In the case of higher blends of biodiesel, storage and handling become increasingly important to keep water out of your tank and to make sure your fuel is properly blended and treated for winter use, says Forester. Equipment tanks containing B100 should never be stored outside from October to March, except in far southern climates where the temperatures stay above freezing year-round, he says.

B100 biodiesel has a higher cloud point than No. 2 ULSD or winter-grade diesel fuel and will gel at 25 to 50 degrees Fahrenheit. But B5 typically does not gel until the temperature gets well below zero (untreated) and minus-30 degrees (treated).

“What people need to remember is that cold-weather use and additives are important with all diesel fuels,” says Scharingson. “So is having a dry tank – if water has a way into a tank, it will be there no matter the fuel. The proper storage and handling coupled with good winter additives allow fleets to use biodiesel blends year-round.”

Engine warranties

According to the National Biodiesel Board, most engine manufacturers have approved the use of biodiesel in levels up to B20. Several statements from the engine companies are available on the National Biodiesel Board (NBB) website: nbb.org.

Before using biodiesel, check with your engine OEM about compatibility, as not every OEM has approved it for all models. B100 biodiesel as a fuel is not warranted by equipment manufacturers except some farm implement companies such as International Harvester, Forester says.

But by law, gas stations and truck stops in Minnesota have been selling B5 in the winter and B10 in the summer. Starting in May 2018, the warm-weather requirement will increase to B20. So far, no major issues or complaints have surfaced.

Most engine OEMs specify that the biodiesel must meet ASTM D6751 to guarantee warranties, while others are still adopting D6751 within their companies or have their own guidelines for biodiesel use that were developed before the approval of D6751. It is anticipated that the entire industry will incorporate the ASTM biodiesel standard into owner’s manuals over time.

Tariffs and credits

Recent items in the news could affect biodiesel prices in the future, although the industry says the impact will be minimal. The biodiesel tax credit was recently approved retroactively for 2017 but not for 2018, although the industry is operating as if the credit will eventually be passed retroactively for this year, too. The United States also imposed tariffs on biodiesel imported from Indonesia and Argentina last year.

Scharingson predicts the tariffs on imported biodiesel will have little effect on prices. “It’s pretty clear the domestic producers can more than offset that,” he says. “We haven’t seen any change in our prices nor have our customers at the pump.”

Is paraffinic renewable diesel the perfect fuel?

With rare exceptions for certain types of agricultural equipment, no fleets are using biodiesel in blends stronger than B20.

However, refiners in recent years have developed a different process to make a diesel-like fuel out of the same raw materials as biodiesel (plant and animal fats). The industry is calling it several names: renewable diesel, renewable hydrocarbon diesel or paraffinic renewable diesel. For our purposes here, we’ll call it paraffinic renewable diesel.

Last year, Cummins approved paraffinic renewable diesel fuels as a 100 percent substitute for petroleum derived ULSD in its B4.5, B6.7 and L9 engine platforms, both on and off highway and all year models. In its statement on this, Cummins said no additional engine maintenance is required, and the same fuel filters can be used. The report also noted that paraffinic diesel can be easily blended with standard diesel at varying percentages, including winter-grade fuels, and has the same stability and cold properties as conventional diesel, which means it can be used and stored in the same ways.

Cummins spent 18 months running 100 percent paraffinic diesel fuel in its engines to validate these claims. The report noted that engine performance remained stable and consistent. The only difference Cummins’ tests found was a zero to 6 percent fuel-economy detriment because of the lower density of paraffinic fuel. This, however, was duty-cycle dependent. The company says it is continuing to evaluate and validate the use of 100 percent paraffinic fuels, like RHD, in its other high horsepower and heavy-duty platforms.

Paraffinic renewable diesel is basically pure hydrocarbon with high cetane and no aromatics, says Forester: “It is as close to running a diesel engine on the perfect fuel hexadecane that you can get. As such, the engine companies can’t help but accept it at 100 percent for their engines. If you can buy 100 percent paraffinic renewable diesel, I would expect it to function in terms of storage and handling very similarly to ULSD with no biodiesel added.”

By comparison, B100 biodiesel contains a lot of byproducts. All of these byproducts and potential contaminants give the engine companies major heartburn, which is why so many do not warranty their equipment for greater than B20 blends, Forester says.

Scharingson says paraffinic renewable diesel produced by his company has a lower sulfur spec – 5 parts per million compared with petro-diesel’s 15 ppm. That’s better for your engine since sulfur contributes to sulfuric acid inside the engine and is one of the factors that eventually compromises the effectiveness of your lube oil. He also says the fuel has a minimum cetane number of 65, compared to the minimum spec for petro-diesel of 40 and a cetane spec of 47 for biodiesel. Fuels with a higher cetane number have a shorter ignition delay, meaning they are easier to ignite inside a compression (diesel) engine.

Still, paraffinic renewable diesel isn’t likely to replace biodiesel anytime soon. The large demand for paraffinic diesel on the West Coast makes it challenging for fleets and retail outlets to get enough supply. And biodiesel’s price, supply levels and its smaller carbon footprint will make it an easy choice for some time to come.