I left the office with a fully-charged new tablet that died on the plane out. Then I found my camera had a corrupted SD card. The in-flight entertainment screen on a 5-hour flight didn’t work in my seat—just my seat. And as soon as I reached the rental car counter, the computer went on the fritz.

Not a good prelude for taking a 180-foot ride in what is billed as the world’s tallest aerial lift, but it turns out the folks at Genie had my technology jinx well in hand. In the expert hands of training manager Scott Owyen, the SX-180 gave this editor a smooth ride to daunting heights (see video below).

Now making its U.S. debut after its world introduction at the Bauma trade show in Munich last year, the Genie SX-180 self-propelled telescopic boom is aimed at rental customers who’ve had to resort to truck-mounted aerial lifts and cranes with man baskets to reach required heights.

“The tallest self-propelled boom before this went to 150 feet,” says Frank Schneider, Genie super boom product manager, Terex Aerial Work Platforms. “The extra 30 feet gives us access to a world of applications, including oil and gas industries, commercial and industrial construction and wind turbine work. Now you can use an aerial work platform on an 18- to 20-story building versus a 12- story building.”

With a 180-foot vertical reach and 80-foot horizontal reach, the SX-180 propels an 8-foot-by-3-foot, 750-pound capacity, two-occupant platform. A 10-foot, 180-degree rotating jib allows workers to position themselves front-center to the work at hand; the machine can be driven at full height.

“It allows workers to go to a new height; it’s almost 25 percent greater than what they’ve had access to in the past,” Schneider says. “Even more impressive, it has a max outreach of 70 feet 120 feet up in the air. That gives you an incredible range of motion and working envelope without having to reposition the boom. And you can get to full height in under 5 minutes.”

Design challenges

Genie’s Moses Lake, Washington, 500,000-square-foot plant—situated in three hangars on a former U.S. Air Force base—employs more than 1,200 people and produces 16 models of aerial lifts and telehandlers.

Genie’s Moses Lake, Washington, 500,000-square-foot plant—situated in three hangars on a former U.S. Air Force base—employs more than 1,200 people and produces 16 models of aerial lifts and telehandlers.The design challenges in creating the SX-180 centered around basic physics, Schneider says: “The base has to expand as the height expands. You can either make the base bigger or make it as heavy as possible.

All hydraulic hoses on the SX-180 are bulkheaded. “If a hose goes out, you just need to replace a small chunk of hose instead of the entire line,” explains Frank Schneider, Genie product manager.

All hydraulic hoses on the SX-180 are bulkheaded. “If a hose goes out, you just need to replace a small chunk of hose instead of the entire line,” explains Frank Schneider, Genie product manager.Making it heavier really wasn’t an option because it would make it more difficult to move around. So one innovation was getting a chassis that would give us the base footprint to get up to 180 feet, while still making the base small enough to get onto a standard trailer.” The X-chassis design is also used on Genie’s ZX-135 articulating boom.

The SX-180 retracts to 8 feet 2 inches wide by 40-feet long “so fleet managers already have the trailers to transport this equipment without worrying about over width or over height permits,” Schneider says. The 55,000-pound machine does, however, need an overweight permit.

The second challenge was making the boom strong enough to lift the platform to full height. Genie used 100-ksi steel, which is strong enough to bear the required weight, but can be used at a reduced plate thickness, thus keeping the overall machine weight down.

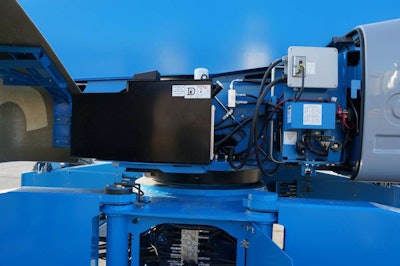

When the SX-180 goes to Tier 4 Final this year, it will have a 74-horsepower Deutz engine. As in most of the Genie product line, the unit will feature a swing-out engine tray to give service access around the engine.

When the SX-180 goes to Tier 4 Final this year, it will have a 74-horsepower Deutz engine. As in most of the Genie product line, the unit will feature a swing-out engine tray to give service access around the engine.Third, Genie engineers knew they had to get the right amount of hydraulic flow to the lift cylinders in give the boom both speed and multifunctionality. “In order to be productive, you have to be able to do more than a single function at a time,” Schneider says. “We did that with a new hydraulic pump system with back-to-back pumps.”

Rental companies are expected to be the primary buyers of the SX-180. Scheinder says rental rates will typically run around $10,000 to $15,000 a week, which he says is still cheaper than competing solutions to reach this height. “You would spend at least five times the amount with truck-mounted boom or manbasket-equipped crane,” he says.

In the video below, take a ride with me as Scott Owyen, global training manager, Terex Aerial Work Platforms, talks me up to 180 feet, to literally get a bird’s eye view of Genie’s Moses Lake, Washington, operations.