To prevent costly contamination, a closed system with approved DEF handling materials is your best bet for refills in the field.

To prevent costly contamination, a closed system with approved DEF handling materials is your best bet for refills in the field.When it comes to the new emissions-compliant engines, OEMs are preaching the need to maintain clean fluids. But when it comes to the purity of your diesel exhaust fluid (DEF), the cleanliness specs are off the charts.

All it takes to contaminate a 5,000-gallon tanker truck of DEF is one-tenth of a teaspoon of a metal like copper, zinc, chromium or nickel says Luke Van Wyk, owner and sales manager of Thunder Creek Equipment. If you don’t know what a teaspoon looks like, those tiny salt packets you get in a fast food restaurant hold about a teaspoon. Now imagine one tenth of one of those stirred into a tanker truck full of DEF. Other contaminants such as iron, aluminum, phosphorous, magnesium, calcium, sodium and potassium can also ruin a tanker-full of DEF in amounts of two teaspoons or less.

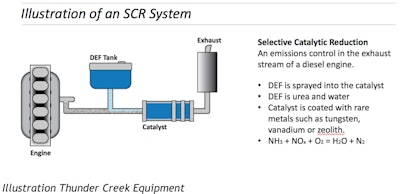

The reason such small amounts of trace metals cause problems is because these elements build up inside the exhaust catalyst that turns the DEF and diesel exhaust into harmless water vapor and nitrogen, says Van Wyk. The hardware that accomplishes all this is known as the selective catalytic reduction system (SCR) and compromising it with contaminated DEF could create a host of problems including:

• Increased DEF consumption

• More pollution in the exhaust

• SCR system shutdowns leading to engine shut downs

• Damage to catalyst, which could cost tens of thousands of dollars to replace

• Void manufacturer’s warranty

The American Petroleum Institute developed a standard for the purity of the DEF used in vehicles and equipment. As long as you purchase and use API certified DEF, the purity of the delivered product should be guaranteed. But once your DEF is pumped out of its certified source or container there are lots of ways it can become contaminated downstream.

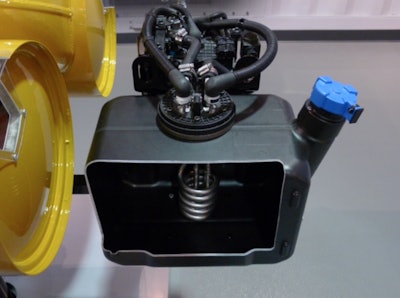

This cut-away of a DEF storage tank showing the heating element that will thaw frozen DEF in equipment in the field.

This cut-away of a DEF storage tank showing the heating element that will thaw frozen DEF in equipment in the field.Tips for keeping DEF clean

• Never handle DEF using anything other than DEF-safe containers and hardware. Most standard pump fittings and components contain zinc, nickel, chrome, brass, or aluminum and can contaminate your DEF. The only acceptable metal component material is stainless steel. The containers for DEF are made from high-density, crosslinked polyethylene (XLPE).ISO standard 22241 covers these specs in more detail.

• Avoid contaminating your DEF during transfer. Never use steel or galvanized transfer containers. Don’t use the funnel you use for oil fills, brake fluid, coolant or other fluids. Use only DEF-approved materials and keep the equipment, area you are working in and the fill points spotless. Be especially vigilant about dust and dirt in the field. And never refill an opened container.

• Whenever possible use a closed system to dispense your DEF. These systems, designed specifically for DEF handling, are sealed much like a beer keg so that no external contamination can get into the fluid as it’s being transferred. They range from, large trailer-mounted systems to simple sealed containers intended for single use. Open systems, such as jugs with screw-off caps sold at retail, are not recommended for field use due the likelihood of dust and debris contamination in the air and around the fill portal.

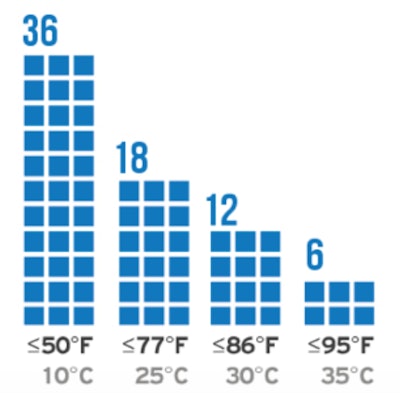

• Monitor the shelf life. The shelf life of DEF is directly proportional to the temperature it’s stored in. In the cooler, middle and northern parts of the country you will typically get 18 to 36 months of shelf life. For southern states and warmer climates this may only be 12 to 18 months. See chart below.

• Finally, do not use any additives in your DEF that claim to prevent freezing or say that they are DEF anti-freeze. There are products that claim to do this but they don’t have any official sanction from the API and could very well damage your SCR system.