Why are mini skid steers, compact tool carriers, compact utility loaders – or whatever you want to call them – so popular?

Their manufacturers’ product managers cite the smaller dimensions and overall versatility as the primary reasons these machines are highly sought after for any environment.

With their track system, compact utility loaders cause minimal ground disturbance. And they can operate a wide range of tools.

"CULs are so versatile and offer multiple attachments, they function as a real workhorse on any jobsite," says Kyle Cartwright, Toro product marketing manager.

Even with a bucket attachment, they can move all types of material and perform small grading and clearing tasks.

“They can handle many jobs that used to be performed by hand, such as demolition, carrying materials, and digging trenches,” Cartwright says.

Where CULs Excel

Vermeer

Vermeer

“We have seen an uptick from contractors starting to purchase more of these,” said Trevor Koolmees, Vermeer Corporation product sales manager.

Available models from various manufacturers range from 500 to 3,000 pounds of operating capacity. Among the largest on the market currently is Ditch Witch’s SK3000 with a 3,000-pound capacity that rivals small full-size skid steers.

A significant difference between the mini skid steers and their larger CTL and skid steer cousins is the 360-degree vantage point.

“Mini skid steers are very popular in the construction industry because of the visibility from the stand-on platform," says Brant Kukuk, Ditch Witch compact equipment product manager.

In a cab, operators typically have a rearview camera that may be combined with a radar detection system to increase visibility from the cab. Operating in reverse takes up close to half of any operation on a jobsite.

On a stand-on loader, operators can easily get on and off the machine to complete other tasks or remove obstacles.

“You can turn the operator into a working hand for a few minutes and then jump right back on and be an operator,” Kukuk said.

Stand-on platforms for most of the OEMs that offer mini skid steers are set up to shut down the machines when an operator steps off.

“If you're on and off the machine frequently, these are very good machines to select for that,” says Mike Fitzgerald, Doosan Bobcat marketing manager, adding that while mini skid steers are smaller, they are a good size for cleaning up brush, moving materials around a jobsite, breaking concrete and more.

“They do have engines that are under 75 horsepower, so you don't have to worry about some of the things like diesel exhaust fluid or anything like that,” he says. “It's a simpler system to what you'll see on some of the bigger equipment.”

Rather than taking over the role of a full-size CTL or skid steer, mini skid steers can help increase productivity and complement the work of larger machines. They bridge that gap between manual hauling methods like wheelbarrows and the larger ride-in equipment.

“They're used a lot for working around those tight areas where you can get these machines in there and don't have to have a wheelbarrow to move materials in and out,” Fitzgerald says.

Saving Workers' Backs

Toro

Toro

“Using the right equipment brings efficiencies that can help reduce overall costs and complete jobs quicker,” Toro’s Cartwright says.

Labeled by some as more of a landscaping contractor’s tool, the mini skid steer is versatile enough to be effective for a variety of construction applications.

“If you have a large excavation project, and it's very open, then bigger equipment is much more suited to that,” Fitzgerald said.

However, many jobsites are now tighter with more confined lot lines, such as renovations in urban areas.

“It really depends on what the application is and what the contractor is working around as to what will fit in,” Fitzgerald said.

Due to their versatility, the mini loaders also have a quicker return on investment and serve as an almost immediate labor savings in most cases by increasing productivity on jobs that were previously being done manually.

“You're replacing essentially two to three labor workers with these mini skid steers,” Vermeer’s Koolmees says. “As labor becomes harder and harder to find, your employees are going to want a mini skid steer rather than doing everything by hand.”

Mini skid steers are also easy to operate.

“CULs can instantly increase productivity of any jobsite and, with intuitive controls, can be operated by almost anyone,” Cartwright says. “Contractors who make the most of the flexibility and ease-of-use can increase productivity on their jobsites.”

How to Choose

Picking the right mini skid steer for the specific work you do is important.

“With the functionality of a mini skid, get it for what you're going to be wanting it for,” Koolmees says.

He added that it is important to consider the overall versatility of the machine and whether it can get the job done.

Questions such as: what tasks will you be performing most often? Is there a certain lift height you need? How heavy is the material you will be hauling most often?

Any quality dealer should be asking similar questions and more to help narrow your options.

Determining the correct size of machine comes down to the rated operating capacity, width, and weight.

“All of these are compacts, so you don't really have to worry about width,” Koolmees says.

With so many manufacturers now in the mini skid steer market, selecting one supported by a responsive dealer network will be necessary for service.

Other options to consider are radial or vertical lift, tracks or wheels, and hydraulic flow rates to accommodate attachments. Some contractors, mostly on the landscaping side, will consider ground pressure.

The Right Attachment

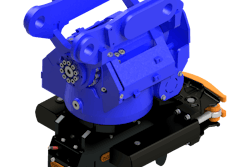

Bobcat

Bobcat

For example, he says, a mini skid steer with the right attachments can replace a dedicated trencher, tiller, auger, and many other tools.

“The real magic about CULs is they can perform a multitude of tasks on the jobsite with a simple changeout of attachments,” Cartwright said.

Contractors can rent attachments they don’t use regularly. Some attachments require specific plates, while others fit universally across brands.

Buckets are by far the most universal attachment and can be used for digging, moving loose material, grading and leveling.

Grapples and forks are other widely used options for moving building supplies, brush, rocks, and more around jobsites.

Utility or landscape contractors doing smaller jobs will often use a trencher or vibratory plow. Auger attachments can be used for post installations or planting trees, shrubs, and plants. Stump grinders are also popular.

How to Keep it Running

Maintenance is specific to each machine and can differ by each product's features and design.

Most OEMs have a lift-up hood or easy-access panel to reach the daily checkpoints of oil and fuel levels and filters.

“If you make it easy to maintain,” Fitzgerald says, “then there's a higher probability that they will maintain it properly, which if you maintain something properly, you get longer life out of it.”

Dealers can help develop a comprehensive maintenance schedule and follow the OEM guidelines. A general recommendation is to make a daily inspection part of a preventative maintenance plan.

“The idea is to check small issues before they become larger issues that can cost a contractor time and money,” Cartwright said, noting that operators can perform a thorough visual inspection while washing the machine.

One checkpoint the product managers each cited as being essential was a review of track tension.

“You need to make sure it's properly tensioned, not over- or under-tensioned," Kukuk said. “If it's properly tensioned, you're not going to worry about de-tracking or extra component wear that's not needed.”

He said at minimum track tension should be looked at daily and reviewed weekly.

Cartwright suggests the following checklist to complete before each use of a CUL:

- Perform a Thorough Visual Inspection: A contractor will want to inspect the entire machine for damage or wear including a visual inspection of the tracks, wheels, fittings, body, controls, guards fuel lines, battery terminals, and any attachments.

- Check and Top Off Fluids: Make sure engine oil, gasoline (or diesel), battery water, and hydraulic fluid are all at the correct levels.

- Keep Filters Clean: Air filters or carbon canisters should be inspected and cleaned or changed regularly.

- Lubricate Properly and Tighten Connections: Grease all pivot points and tighten all nuts and bolts before heading out into the field to reduce wear and extend the life of the machine’s components.

- Safety Check: Make sure the parking brake is engaged (if applicable), and that the traction control lever is returned to neutral. Also make sure that auxiliary hydraulics are disengaged, as many compact utility loaders or mini skids will not start with the auxiliary hydraulics engaged.

Looking for more information on the best mini skid steers on the market? Check out our buyer's guide: Stand-On Mini Loaders: Doing So Much More Than Loading