At the Bauma show last week in Munich, Rubble Master took the wraps off its new flagship machine.

The 120GO! tracked mobile impact crusher features an output of up to 350 t per hour and can be used to crush a wide range of different materials, Rubble Master says.

This crusher allows for driving and crushing in a single move and optimizing material flow while outputting a higher quality product thanks to a specially designed crusher unit which can be outfitted with two or four hammers and has three rotor speeds.

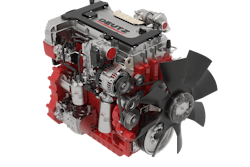

The machine, which weighs in at just under 75,000 pounds, is powered by a 6-cyliner John Deere engine rated at 256 kW (343 horsepower). Feed material size is an edge length max of 850 mm and the inlet opening is 950 x 750 mm. The feed unit is an asymmetric vibro feeder with 4 cubic meter and two 3.1 kW vibrator motors.

As for the discharge belts, crushed material is handled by he main belt, a folding conveyor that is 1,200 mm wide and folds into transport position hydraulically. The main belt has a discharge height of 3,600 mm. Screen material is handled by a second folding conveyor that is 500 mm wide at a discharge height of 2,550 mm.

Available options include:

- Dust suppression using water spray inside crusher and at outlet and belts

- Diesel filling pump

- Crusher hammer charging system

- Cable remote control

- Central lubrication system

- Subfloor

- Active pre-screen