The L350H. Photos: Wayne Grayson

The L350H. Photos: Wayne GraysonExpected to be available early next year, Volvo debuted the all-new flagship of its wheel loader range, the L350H. It features a 10-percent improvement in fuel efficiency and a host of other productivity improvements, as well as a new design.

So what does it take to design a flagship unit? “Number one, you want to come out with something that you really believe in and is going to take you a step forward,” says Stefan Salomonsson, product manager, Volvo Construction Equipment North America. “With this unit, I think we’ve done that. We were leading this class before when it comes to fuel efficiency and production. With this product, we took another step forward with an additional 10 percent in fuel efficiency.”

Unveiling of the L350H drew a crowd during the opening morning of ConExpo-Con/Agg 2017.

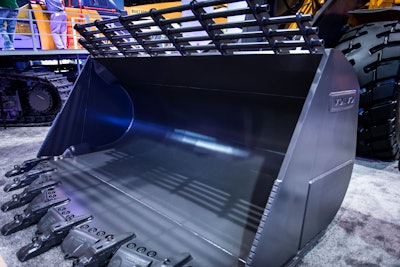

Engineered for efficiency, the L350H is fitted with next-generation hydraulics and powered by a Tier 4 Final D16J engine, for high torque at low rpm. For quarry production, the L350H comes with a higher capacity 9.5-cubic-yard rock bucket.

A similar look and feel will be seen through other sizes, Salomonsson says. For example, the 260 shares the same type hydraulics, while the transmission and gear changing set up are also similar so that an operator can move between machine sizes and get the same feel and familiarity throughout the line. “You’ll feel at home in the cab,” he says. “You’ll recognize it.”

More production

The new load sensing hydraulic system works in greater harmony with the drivetrain, increasing response times (and lifting and lowering speed of the newly designed buckets) resulting in up to 5-percent faster cycle times. The hydraulic system and drivetrain improvements, coupled with the latest Volvo engine technology, make the L350H up to 10 percent more fuel efficient in comparison to the L350F it replaces.

To boost the machine’s performance and reliability, the loader has increased clearance between the rear fenders and tires, allowing greater access when fitting tire chains, thereby reducing the risk of damage to the body of the machine.

Efficiency as standard

The L350H is equipped with technology dedicated to reducing fuel consumption and engine emissions.

Volvo’s Fully Automatic Power Shift (FAPS) system allows for machine operation in the optimal, fuel efficient gear, according to speed, kick-down and engine braking, enhancing fuel efficiency.

This is complemented by an eco-pedal, with a push-back mechanism that engages when engine rpm is about to exceed the most economic operating range. Sensing the resistance, the operator can then reduce the pressure and continue within the fuel-efficient range. However, if full engine speed is needed, the eco-pedal mechanism can be overridden.

A comfortable ride

New from the inside out, the L350H has been built with operator comfort in mind.

“We’ve always been good at making the cab comfortable,” Salomonsson says. “If you’re going to be in a machine for 10 or 12 hours a day and want to keep production up, you have to ensure the operator is comfortable. That includes the cab, the suspension, and the seat.”

The new cab boasts excellent visibility, minimal noise and vibration levels, as well as Automatic Climate Control (ACC), to ensure an always comfortable climate in the cab. Controls can also be configured to suit operator preferences, adding to the overall comfort of the operator.

The next generation Contronic monitoring system and digital display incorporate the latest improvements in intelligent Human Machine Interface (HMI). The system monitors operation and performance in real-time, providing the operator with all necessary machine information.

Safety and service

To make routine maintenance and daily service checks quick and easy, the design of the engine hood has been improved, allowing complete access to the engine compartment. Engine side hood panels and a platform around the cab also enable operators or technicians to move easily around the machine.

Safety is engineered into the loader with ergonomically spaced steps on entry to the cab and sturdy handrails, for easy entry and exit. A remote door opener, operated via a button located on the rear left cab post, facilitates easy access to the cabin. In addition, LED lights, installed on the cab entrance, safely illuminate the area. When operating in the dark, long-life LED work lights and reflective stickers that follow the machines contours also help to increase machine visibility.

Operators can be sure of their surroundings with the optional rear-view camera, equipped with a new adjustable mounting bracket. New side-view mirrors also make it easier for the operator to safely monitor operations from all angles.