Compaction cautions

Never bypass a machine’s safety features

By Amy Materson

The accident: Using a borrowed compactor, an operator was compacting soil for a new road. The machine had a faulty starter system – when used on rough terrain, the engine

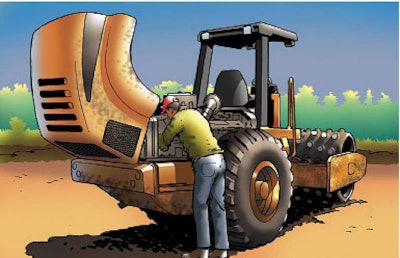

The bottom line: A post-accident investigation determined the machine had difficulty starting all day. To restart the machine, the operator had to stand on the rim of the left wheel assembly, reach across the tire and use a 7/16-3/8-inch offset open end wrench to jump across the starter solenoid terminals. Both the guard over the side of the engine where the solenoid was located and the operator’s manual were missing. The general contractor stated he did not know the machine was malfunctioning.

Easy avoidance

A number of mistakes were made that led to this worker’s death. When using compaction equipment, remember the following:

Don’t use defective equipment. Inspect your equipment prior to use. If you find a malfunction, let your supervisor know so the machine can be placed out of service until repairs can be made.

Respect the machine’s safety features. During your inspection, ensure safety features are operational, and comply with all warning labels. Never bypass equipment safety features to start or run a machine. Know ahead of time what procedures are in place in the event of equipment malfunction.

Follow proper procedures, especially during a malfunction. Although the compactor’s manufacturer didn’t recommend jump starting the machine in every instance, the operator’s manual – which was missing in this instance – outlined an acceptable procedure. Had the manual been in the machine, the operator would have had access to the correct information, which directed setting the propulsion lever and parking brake to prevent movement upon ignition.