Winch Repair: Replacing Planetary Gear Sets

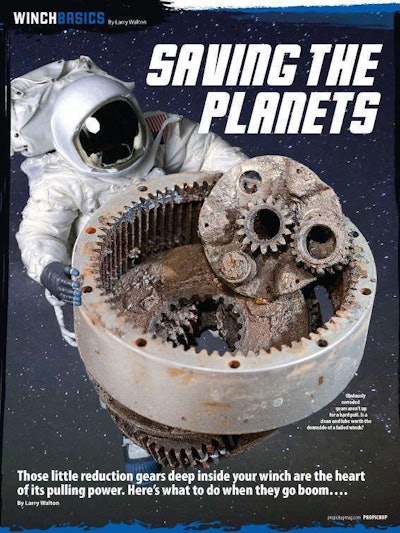

Those little reduction gears deep inside your winch are the heart of its pulling power. Here’s what to do when they go boom….

By Larry Walton

Weekend off-roaders think getting thoroughly stuck is a good way to spend a Saturday afternoon. But it’s the last thing those of us who work outdoors for a living want to happen.

If you’re on a jobsite with equipment running, you can get a pull easy enough.

If it’s just you and your pickup, you’ll be digging the winch remote out of the glove box and reaching for your rubber boots, confident that the winch is in good operating condition.

When all goes well, the winch makes getting unstuck easy.

But sometimes there’s a problem. The winch can be pulling then suddenly there’s a cracking noise and the cable stops reeling in.

That problem is deep inside the winch. And it’s not a field repair. But it is fixable.

In our on-going series on winch repair and maintenance, we are endeavoring to make sure that winch is ready when needed.

We’ve diagnosed and fixed electrical and winch motor-related issues. Now it’s time to check into the guts of the planetary gearsets.

WINCH DISASSEMBLY 101

Before disassembly, leave yourself plenty of room on a clean workbench to spread out the parts for inspection. Organize the components in the order they come off of the drive shaft or are stacked in the housing.

Pay special attention to the direction and order of the carriers and sungears that make the connections between planetary gearsets.

In a mid-frame winch like Warn’s M8000, take care when pulling the spring-loaded brake assembly from the drum that you are ready to place it in a similar diameter cylinder or have a clamp handy to keep the components together.

Some winches that have been operated while submerged and have gearsets that are packed full of a clay-like mixture of muddy water and grease, making gear movement sluggish and promoting corrosion.

Some winches that have been operated while submerged and have gearsets that are packed full of a clay-like mixture of muddy water and grease, making gear movement sluggish and promoting corrosion.Most of the diagnosis for the gearsets will be visual. Look first for obvious broken pieces, corrosion, rust or sludge build-up.

Any of these conditions can explain a malfunctioning winch.

If you have time to clean, lube and test the gears, make sure you use the proper grease for the winch you are working on; Warn uses moly extreme-pressure, low-temperature grease in the gearsets.

(Warn recommends that a submerged winch be taken to one of their certified service centers.)

If you tackle it in-house, it takes some patience, good solvents and some luck to restore such gearsets to function, assuming the components are not already damaged.

Aside from corrosion and material intrusion, you should be looking for broken parts. There are lots of teeth to inspect in the sun gears, ring gears and planetary gears.

When you find a problem, look for corresponding issues. “If there is a broken tooth on the planetary gear, the ring gear is likely to have damage,” says Johnson.

Warn sells replacement planetary gear sets to replace damaged ones.

Warn sells replacement planetary gear sets to replace damaged ones.You are always looking for debris, but be especially diligent when you know a tooth or two is not where it is suppose to be because pieces from a broken gear can migrate to other areas and cause more damage.

Finally, inspect the gears for movement and slop; planetary gears should spin with finger pressure within their housing.

Too much lateral play in bushings indicates a replacement is needed as well. (Worn bushings can cause more trouble than you might think.)

Locating Replacement Winch Parts

You can look up exploded-view diagrams of winches online to find the replacement part numbers. With part numbers in hand, you can order parts from the manufacturer or an approved service center.

For Warn owners, warnserviceparts.com lets you click on a part in the winch exploded diagram to put it in the shopping cart – very nice!

- Mile Marker; milemarker.com

- Ramsey; ramsey.com

- Superwinch; superwinch.com

- Warn; warn.com