The new Drone 2s offers between four and six times more surveying accuracy than its predecessor the Drone 2.

The new Drone 2s offers between four and six times more surveying accuracy than its predecessor the Drone 2.Drone maker and aerial intelligence platform Kespry has introduced a big update to its Drone 2 hardware that greatly improves the unmanned aircraft’s performance while increasing its accuracy and reliability.

Last year, Kespry launched Drone 2.0, a complete drone solution aimed at construction and surveying that fully integrates drone hardware and cloud-based image rendering software in order to provide a drone that not only flies itself, but delivers ready-to-use imagery and survey data with almost no operator intervention required. Flight planning is done from an easy to use iPad app and the flights themselves are automated, as is all data generation inside Kespry’s cloud platform.

The company says its new Drone 2s provides survey-grade precision for the architecture, engineering and construction (AEC) markets with accuracy that is between four and six times greater than the Drone 2.

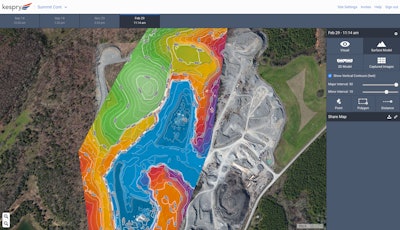

An example of Kespry’s cloud-generated survey data for mine planning.

An example of Kespry’s cloud-generated survey data for mine planning.Thanks to a new GNSS base station receiver on the ground, the Drone 2s can now deliver accuracy of 2 to 10 centimeters. Rather than having to set up multiple ground control points as is typically necessary with drone surveying, Kespry says the base station acts as a single survey control point. During a flight, images from the Drone 2s and data from the base station are collected simultaneously, Kepsry says. Both of these data sets are then automatically uploaded to the cloud for processing. In just a few hours the platform delivers survey-grade data.

The Drone 2s also integrates Post-Processed Kinematic (PPK) technology to increase the accuracy of its photogrammetric aerial images. Kespry says PPK has improved the platform’s speed and efficiency as well as the reliability of gathering survey-ready data in commercial and industrial environments.

Speaking of harsh industrial environments, Kespry says the Drone 2s’s automated flight system includes obstacle avoidance and can fly 500 acres in one survey session.

In the Kespry video below, David Lloyd, a mine planning engineer for Oldcastle Materials subsidiary APAC Central, says the Kespry system has decreased the amount of time it takes to generate a survey of an area from nearly a week to just a few hours.

“We needed the full topographic survey of the entire area so they could do their initial cut and fill, their initial engineering design. And it was a wreck of an area, it was old pit. It had been disused for years,” Lloyd explains in the video. “We could have done that with our scanner system. It would have taken a meeting to plan where we going to drive roads with the dozer, a few days to drive those roads, a full day of driving the scanner around to cover everything. We used the drone instead and we were on site for two hours total. And that’s when it really struck me, this is a lot easier.”

“When we started working with the Kespry Drone System about a year ago, we were trying to find ways to be more efficient,” adds Murry Cline, vice president of operations with APAC-Central, in a statement included in a Kespry press release. “We can now fly our Kespry Drone 2 over our entire 60-acre aggregate site in about 15 minutes. Previously, it would have taken us about a day or a day-and-a-half to do the inventories and a few more days to do the calculations.”