Known for its GPS grade control systems for large equipment, Topcon has expanded into the compact arena with its new automatic 2D grade control for compact track loaders.

The 2D-MC system works with a box blade attachment and connects directly to the CTL’s in-cab controls. The exterior masts attached to the box blade work with a typical jobsite rotatary laser.

The operator sets the grade with a tablet mounted in the cab. The system uses a CAN bus connection. “It goes right into the brain of the equipment,” said Brandon Jaynes, company spokesman, at the Topcon booth at World of Concrete. “You can get this up and running in about 15 minutes. It’s an affordable cost of entry for midsize contractors who are looking to do more with what they have.”

{Related Content: Topcon’s MC-Mobile: Intuitive Software at Affordable Cost}

The 2D-MC system is compatible with major brands of compact track loaders that weigh at least 8,000 pounds. It can do finish grading for such things as house pads, drainage, roadside rights of way, slope work, sidewalk grading, road base replacement, parking lots, sports fields, landscaping, indoor work, concrete site prep.

It is designed for precision and increased efficiency. The operator no longer has to get in and out of the cab to make adjustments to the blade.

“Now they set that grade, go almost at full speed, depending on what they’re pushing through, and the grade that they ask the system to deliver is the grade that they get,” said Oscar Cantú, Topcon construction content manager.

He adds that customers are often attracted to the product for a specific purpose, but over time they realize they can take on more complex work.

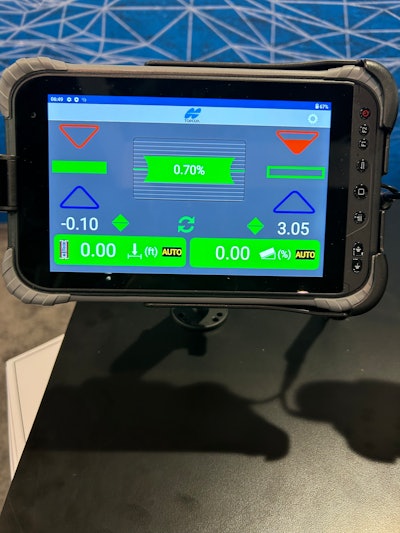

Topcon says it kept the tablet control for its 2D-MC's in-cab monitor simple for compact track loader operators to set grade and see their progress.Equipment World

Topcon says it kept the tablet control for its 2D-MC's in-cab monitor simple for compact track loader operators to set grade and see their progress.Equipment World

In one testimonial, a customer said a house pad project that normally took three days was completed in only six hours with 2D-MC.

The 2D-MC system can be purchased already integrated onto Level Best and SharpGrade box blades. The attachments with the system come ready to work. It takes about 3 hours of training for someone who has never used grade control, Cantú says.

“You put a battery in a rotating laser, set it up on a tripod,” he explains, “go out with a level rod that the rotating laser measures to, get in the cab, set your grade – you're going. The learning curve is quite low.”

It’s also easy to adjust grade settings should the grading requirements change.

The system’s in-cab monitor is an Android-based tablet designed to handle the rugged conditions of a construction site. Cantú said the controls were intentionally kept simple with few options to choose.

The 2D-MC system is available through Topcon dealers.