An updated and more engaging version of 360Training’s OSHA 10 and OSHA 30 Construction courses in both English and Spanish has been launched.

To motivate learners, 360training has included game modules and quizzes within the courses to make them go faster and improve students’ chances of passing. This gamified design both enhances learning and increases participation, the company says. Gamification in online courses has also been shown to improve memory, processing speed and reasoning.

The new versions of OSHA 10 and 30 training leverage HTML5 programming that is both more accessible across browsers and mobile-capable. The user-friendly design gets employees in the course, trained and on the job faster, with DOL cards shipped within two weeks, the company says.

"We strive to constantly to enhance courses to evolve with technology through gamification and interactive product enhancements, ensuring they're the best available in the market with an exceptional customer experience,” said Ryan Linders, chief marketing officer at 360training.

HCSS forms simplify jobsite documentation

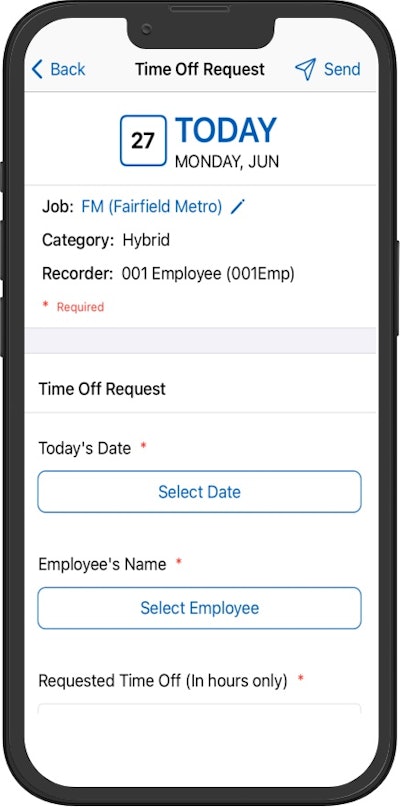

HCSS is introducing HCSS Forms, a digital forms builder to improve worker productivity and eliminate paperwork.

Crews can answer questions online, add photos, generate smart forms and sign off on forms digitally, without manually filling out forms on paper.  Crews can answer questions online, add photos, generate smart forms, and sign off on forms digitally, without manually filling out forms on paper with HCSS Forms.HCSS

Crews can answer questions online, add photos, generate smart forms, and sign off on forms digitally, without manually filling out forms on paper with HCSS Forms.HCSS

HCSS Forms allows workers to:

- Create forms from scratch with customization to enable branded forms.

- Easily share branded daily reports, HR requests and document field updates.

- Create custom owner-specific time and materials reports.

- Manage form access with password protection, QR codes or email notifications.

- Assign forms to one, a few or all jobs, so field members know which forms are associated with specific jobs.

- Hybrid form creation via uploaded PDFs.

The new software also provides a signature workflow so users can add as many signature fields as needed. Users can see which signatures have been signed and which haven't. In addition, status updates on unsigned forms are sent to workers, so they know they must sign off on the form.

HCSS Forms is available in the HCSS Field app as an enhancement to both HCSS HeavyJob and HCSS Safety.

Tenna adds scheduling software

Tenna has expanded its Resource Management software with a new Schedule product.

While Resource Management enables contractors to efficiently request and dispatch equipment and labor resources, Schedule allows for visibility of these resources across divisions and jobsites in a single combined calendar/Gantt chart view for equipment and labor planning and forecasting.

According to Tenna, Schedule helps contractors know more about where their assets are, what assets are needed on upcoming jobs and what might delay or impair an upcoming project mobilization before it begins, so they can outfit their projects with appropriate equipment and labor resources while avoiding costly delays.

“Contractors pay close attention to their two- and four-week lookahead schedules,” says Austin Conti, co-founder and CEO at Tenna. “Using Schedule along with Resource Management enables the connection of field requests to the master schedule.”

With the addition of Schedule, equipment and project managers can see what’s down for maintenance, what’s currently operating on a particular site and what’s scheduled for six months down the road for a job. Project and asset history also can be used as a reference to compare against their construction forecasts, including how long machines were in use on jobsites compared to where they were scheduled.