Embedding tracking and communication capabilities into PPE just makes sense.

Cat says its new Connected Worker system, which will be available during the first quarter of 2022, combines smart wearable technology with the power of analytics to make workers safer. The system was developed by GuardHat.

The Connected Worker consists of three major components: the wearable hardware, software that captures and reports data and an Internet of Things platform that receives field reports and alerts workers of potential safety risks. The system communicates evacuation orders, fall detections, SOS signals and geofence violations.

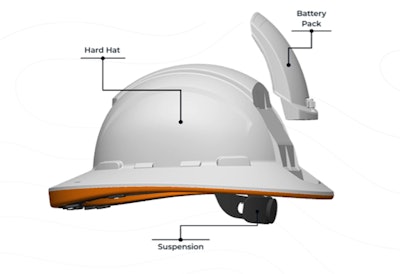

The lithium-ion battery backs last 8-12 hours and can be easily swapped out.GuardHat

The lithium-ion battery backs last 8-12 hours and can be easily swapped out.GuardHat

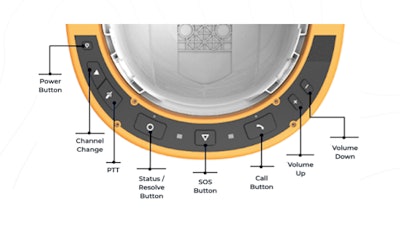

According the the GuardHat website, the HC1 Hardhat is powered by a rear lithium-ion battery pack that provides 8-12 hours of power. The yellow brim is where most of the features reside. Buttons on the underside of the brim include a call button, volume, SOS, status/resolve, push-to-talk, channel change and power button. The maximum weight of the hard hat (with suspension) is 1 pound, 12.2 ounces.

The Cat Connected Worker TA1 tag offers GNSS and Bluetooth tracking outdoors.Caterpillar

The Cat Connected Worker TA1 tag offers GNSS and Bluetooth tracking outdoors.Caterpillar

The system, part of Cat's MineStar Detect portfolio, also has an Android smartphone app to monitor crews outdoors. It allows field managers to communicate with workers, issue SOS alerts, and it can capture images and videos.

Cat says Connected Worker creates a safety ecosystem at the mine site, capturing and storing data — either in the cloud or on a local server — for analysis. Using the SCS, managers can view worker location and data in near real-time to communicate unsafe situations to those in the field. Reports include event reporting, violations and emergency evacuations, location reports with heat signatures that designate highly traveled areas, sensor readings that include temperature, noise, humidity and pressure.

Smart hard hats are gaining traction, especially in the mining sector. The SmartCap, now marketed by the Wenco International Mining Systems division of Hitachi Construction Machinery, attacks a different safety issue: fatigue. It measures alertness and fatigue by analyzing brain activity, often referred to as EEG. Alertness scores, early warning alerts and fatigue alarms are delivered via a smartphone app installed on rugged devices.