It’s a Small, Smart World

Nanotech era draws closer

By Tom Kuennen, Contributing Editor

Nanotechnology offers long-term promise to boost performance of our highway, road and bridge infrastructure. New research is expanding and new applications are materializing. More recently, the long-term environmental impacts of nanomaterials are being studied. But implementation is going to take a long time.

The impact of nanotechnology on highway, road and bridge transportation infrastructure is just beginning. Nanotechnology involves the characterization, engineering and fabrication of matter at the molecular nanoscale, to improve existing products and to make feasible new materials and processes.

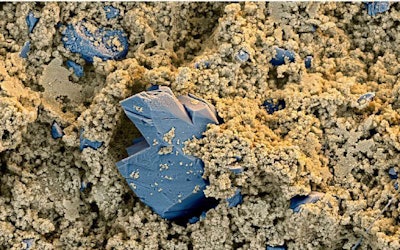

Nanoscale crystal seeds speed up concrete hardening. BASF’s X-Seed hardening accelerator makes additional heat superfluous and the concrete is particularly strong and durable. Magnification 960:1 (by 12 cm in width).

Nanoscale crystal seeds speed up concrete hardening. BASF’s X-Seed hardening accelerator makes additional heat superfluous and the concrete is particularly strong and durable. Magnification 960:1 (by 12 cm in width).Nanotechnology embraces the nanoscale; that is, the range of dimensions from approximately 1 nanometer to 100 nanometers (1 to 100 billionths of a meter). One nanometer is 100,000 times smaller than the width of a human hair. That’s a molecular domain in which devices and systems exhibit properties that aren’t seen at larger scales. In that domain of quantum physics, clusters of atoms and molecules exhibit properties quite different from those found at larger scales. These properties have applications for pavement and bridge infrastructure.

“Nanotechnology should not be implemented in the pavement engineering arena merely because it is a new technology,” states Wynand Jacobus van der Merwe Steyn, Department of Civil Engineering, Tshwane University of Technology, Pretoria, in his paper, Development of Auto-Luminsecent Surfacings for Concrete Pavements. “[T]he application of nanotechnology should allow the engineer to deliver a better product to the client. This may, for instance, be a more cost-effective product, a more technologically suitable product or a safer product.”

Nanotechnology can focus on improving the general properties (e.g., strength, durability) of current materials, the ability to use marginal materials, or the novel application of nanotechnology to enable a safer transportation environment, Steyn says.

Nanomaterials and Construction

Nanomaterials offer significant advantages for the construction industry at large, from making more durable concrete to self-cleaning signs or windows. “The advantages of using nanomaterials in construction are enormous,” says Pedro Alvarez, chair of the Department of Civil and Environmental Engineering at Houston’s Rice University. “When you consider that 41 percent of all energy use in the U.S. is consumed by commercial and residential buildings, the potential benefits of energy-saving materials alone are vast.”

But widespread use in building materials comes with potential environmental and health risks when those materials are thrown away. Those are the conclusions of a study published by Rice University engineering researchers in the July 2010 issue of ACS Nano.

“[T]here are reasonable concerns about unintended consequences,” Alvarez says. “The time for responsible lifecycle engineering of man-made nanomaterials in the construction industry is now, before they are introduced in environmentally relevant concentrations.”

In fact, in a 2010 report, Nanomaterials in the Construction Industry: A Review of Their Applications and Environmental Health and Safety Considerations, Alvarez and co-authors Jaesang Lee, a postdoctoral researcher at Rice, and Shaily Mahendra, an assistant professor at UCLA, find that nanomaterials will likely have a greater impact on the construction industry than any other sector of the economy, following biomedical and electronics applications.

Nanomaterials, they find, can strengthen both steel and concrete, keep dirt from sticking to windows, kill bacteria on hospital walls, make materials fire-resistant, drastically improve the efficiency of solar panels, boost the efficiency of indoor lighting and even allow bridges and buildings to “feel“ the cracks, corrosion and stress that will eventually cause structural failures.

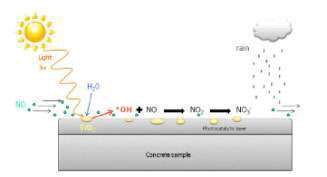

But the authors warn of potential adverse health and environmental effects of widespread use of nanomaterials. In some cases, the very properties that make the nanomaterials useful can cause potential problems if the material is not disposed of properly. For example, titanium dioxide particles exposed to ultraviolet light can generate molecules called “reactive oxygen species“ that prevent bacterial films from forming on windows or solar panels. This same property could endanger beneficial bacteria in the environment.

FHWA Coordinates Research

The Federal Highway Administration (FHWA) has been studying applications of nanotechnology to highway infrastructure for more than a decade.

In 2009, FHWA’s Exploratory Advanced Research (EAR) program hosted a workshop to identify interests and capabilities for nanoscale research that can be applied to highways. The workshop attracted experts from FHWA, university transportation research centers, federal labs and other organizations that are conducting nanoscale research.

The workshop helped shape the scope of FHWA’s further investment in nanoscale research, and supported the development of strategic roadmaps that could outline funding needs for future nanoscale research for highway infrastructure.

“We expect the nanoscale workshop to lead to an overall increase in research targeted at highway program needs,” says David Kuehn, EAR program team director at FHWA. “The workshop was an ideal opportunity to collaborate and leverage nanoscale technology that is being developed for other industries and to accelerate our ability to solve long-term highway research questions.”

“There are multiple potential nanoscale applications in highways,” FHWA says in a 2010 report on the workshop, Nanoscale Approaches for Highway Research. “For example, concrete is a material containing pores on a nanoscale, a result of the chemical reaction between cement and water. Repeated exposure to deicing chemicals causes oxidation, cracks and long-term deterioration to occur in the structure. Utilizing nanotechnology to create smart self-healing materials and structures could lead to less-frequent and faster construction, as well as to increased durability and improved performance, all helping to prevent catastrophic failure.”

Nanotechnology’s ability to produce minuscule MEMS, or microelectronic and mechanical systems, would permit stakeholders to constantly monitor materials, and also could offer improved predictive performance models. “During construction, nanotechnology can allow for embedding increasingly smaller sensors throughout a structure or pavement,” FHWA says. “These sensors could be used for long-term monitoring of corrosion and could offer an invaluable tool in monitoring bridges. By using a car-mounted data reader, information from the embedded sensors could then easily and safely be collected as the vehicle passes.”

As Alvarez, Lee and Mahendra observe, some of this research should be aimed at the environmental aspects of widespread use of nanotechnology, FHWA says. There is concern that unleashing these products on a widespread basis could have unanticipated consequences like something out of a science fiction novel.

Yet nanotechnology in transportation infrastructure also offers environmental benefits, FHWA observes. “[Nanomaterials have the] ability to monitor mobile source pollutants during construction and operations by using nanoscale devices to bind with road-based pollutants,” FHWA says. “Low-cost environmental sensors could monitor the air, water and soil quality, and the technology could allow large-scale monitoring of the operation to continually map pollution levels.”

In a new line of research, nanomaterials such as thin-film technologies may boost use of recycled concrete aggregate (RCA) and reclaimed asphalt pavement (RAP), in addition to reducing alkali-silica reactivity (ASR) in concrete.

“Nanoscale research could lead to an increased use of recycled materials in pavements through a better understanding of bonding at the boundaries of different materials and the design of very thin coatings to improve the workability and durability of recycled materials, which would also help to reduce costs,” FHWA says. “Nanoscale research also could result in the development of smaller, lower-cost sensors, which would use substantially less energy. Self-powered sensors also would contribute to the efficiency and reduced environmental impact of the highway network.”

Concrete Leads Nanoresearch

By far, the most activity in nanotechnology research for pavement and bridge infrastructure has taken place in the concrete industry. There, research is aimed at optimizing concrete strength and durability using nanomaterials, and condition monitoring via MEMS imbedded in the concrete matrix.

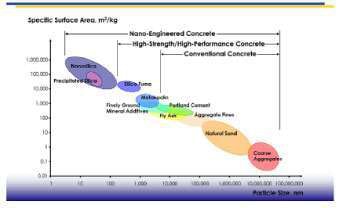

For years, the minuscule size of a particle of microsilica admixture has benefited concrete, as the smaller the silica particle size, the greater the surface area that is presented for reaction within the curing concrete. The much smaller size of nanoparticles now makes possible a geometric increase in performance, and that’s one of the areas of research.

Research in concrete nanotechnology has been well-organized. A workshop at the University of Florida in August 2006 was attended by more than 70 participants, with more than 30 presentations, and focused on the development of a Roadmap for [Nanotechnology] Research for Concrete-Based Materials. The roadmap is destination-oriented, with clearly defined outcomes that will greatly enhance concrete technology and the uses of concrete in structures, including housing, bridges, tunnels and pavements.

That 2006 roadmap identifies research needs such as:

• development of high-performance cement and concrete materials as measured by their mechanical, durability and shrinkage properties;

• development of sustainable and safe concrete materials and structures through engineering concrete for different adverse environments, reducing energy consumption during cement production, and enhancing safety with nanoengineering of concrete materials;

• development of intelligent concrete materials through the integration of nanotechnology-based, self-sensing and self-powered materials and cyber infrastructure technologies;

• development of novel concrete materials through nanotechnology-based innovative processing of cement and cement paste; and

• development of fundamental multiscale model(s) for concrete through advanced characterization and modeling of concrete at the nano-, micro-, meso- and macroscales.

The workshop was followed with a September 2007 conference in Arlington, Va. And, in 2008. a Center for Nanotechnology in Cementitious Systems (CNCS) was created at Iowa State University. The CNCS uses nanotechnology to improve sustainability and performance of concrete roads and structures. The cross-disciplinary nature of the center opens the door to exciting research in this new area, including nano devices that could one day monitor and report on the state of hydration in a mixture and correlate that with the risk of cracking, or predict when traffic can be placed on a pavement.

Other nano-based materials or devices could be used to modify or control the rate of hydration to allow for changes in construction practices or prevent weather-related damage during construction, CNCS says.

In the future, CNCS researchers hope to support 10 graduate students through research projects. Initial projects are being developed, including analysis of the effects of shrinkage-reducing admixtures on the morphology of hydrated cement paste and the properties of air voids entrained in the mixture.

Finally, in May 2010, the First International Conference on Nanotechnology in Cement and Concrete was held in Irvine, Calif. More than 100 delegates from 17 countries and 27 states heard 37 technical papers covering nanotechology in concrete.

Concrete Nanoscale

Nanomaterials can boost strength and resistance to permeability in concrete, according to Celik Ozyildirim, P.E., Ph.D., principal research scientist, and Caroline Zegetosky, graduate research assistant, Virginia Transportation Research Center (now Virginia Center for Transportation Innovation and Research), in their paper Exploratory Investigation of Nanomaterials to Improve Strength and Permeability of Concrete.

“Concrete containing various supplementary cementitious materials (SCMs) such as silica fume, fly ash and slag has improved properties,” they write. “Nanomaterials, new SCMs with possible applications in concrete, have the smallest particle size (less than 100 nm). Nanomaterials are reactive because of the small size and large surface area of the particles, and they have great potential in improving concrete properties such as compressive strength and permeability.”

Ozyildirim and Zegetosky studied a variety of nanomaterials in concrete and compared them to conventional concrete, and concrete containing common SCMs. “The potential benefits of using nanomaterials over other SCMs are high reactivity and cost-effectiveness; in addition, smaller amounts are necessary, resulting in less cement replacement,” they write.

Concretes containing nanosilica and nanoclay were prepared in the laboratory, and compared to concretes containing conventional silica fume, fly ash, slag or only Portland cement. Specimens were tested for compressive strength and permeability. The microstructure of selected concretes with improved compressive strength and permeability was analyzed to explain the improvements.

“The results of this study indicate that some of the nanomaterials tested have potential in concrete applications,” Ozyildirim and Zegetosky write. “The microstructure of the nanosilica concrete was denser and more uniform than the conventional concrete microstructure. In addition, the nanosilica had the largest improvement in both compressive strength and permeability among the nanomaterials tested.”

Download their study from the Virginia DOT at virginiadot.org/vtrc/main/online_reports/pdf/10-r18.pdf

Nanocrystals and Concrete

The private sector has been quick to lead the way to nano-enhanced concretes. For example, a new product, X-Seed crystals from BASF, makes concrete cure faster and reduces carbon emissions.

X-Seed has innovated production of precast-concrete components by serving as a curing accelerator, which the company says not only allows precast concrete units to be produced more rapidly and in better quality, but considerably reduces energy consumption and the associated emission of carbon dioxide (CO2) greenhouse gas.

Cement is produced by pyroprocessing limestone, clay and minerals at high temperatures to produce cement clinker. Pyroprocessing consumes enormous amounts of energy, and releases large amounts of CO2 from combusting the fuel (principally coal or natural gas) and from the chemical reaction the combustion enables. Finally, the coarse-grained clinker is ground into a fine, gray cement powder that hydrates after mixing with water. Calcium silicate hydrate and other compounds crystallize out of the cement during this process to form a compact stone matrix in which aggregates and sand are embedded.

Concrete products are manufactured by placing the uncured concrete mix into forms. Only when the concrete has cured sufficiently can the mold be opened and the component removed. At ambient temperatures (68 degrees F) it can take up to 12 hours to cure, which is valuable production time, during which the formwork cannot be reused. To speed production, the mold often is heated with steam. Although this accelerates production, it also demands much additional energy. Moreover, this treatment can lead to internal thermal stresses, discolorations and a coarser surface of the finished concrete part.

“X-Seed makes heat curing, with all its disadvantages, largely superfluous,” says Dr. Michael Kompatscher, responsible for BASF’s European precast concrete component market. “With this additive, concrete hardens just as fast at 20 degrees C (68 degrees F) as it otherwise does at 60 degrees C (140 degrees F), by a adding something that’s already present in the concrete anyway – calcium silicate hydrate (CSH).”

Countless millions of tiny CSH crystals with a diameter of several nanometers are suspended in liquid in X-Seed, BASF says. Because of their nanosize, more very homogeneously distributed crystallization seeds can be accommodated in the same mass, and thereby promote faster growth. When the concrete cures, further molecules from the cement can attach themselves to these CSH “seeds.” The resulting crystals grow more densely and finally interlock to form the compact cement stone.

When conventional cement hydrates, the CSH seeds first have to form spontaneously from several molecules released from the cement, which accidentally come into contact with each other. X-Seed negates this first barrier to crystallization by providing an excess of these tiny crystal seeds. Another factor is that the CSH crystals form in a more homogeneously distributed manner.

Both these effects of the synthetic crystal seeds halve the time to formwork removal at 68 degrees F from about 12 to six hours, without any detectable differences in the final product, BASF says.

Zeolites and WMA

Warm-mix asphalt (WMA) technologies are a family of processes that produce low-energy asphalt mixes that can be placed at significantly lower temperatures than conventional hot-mix asphalt. At least one additive for warm-mix asphalt operates at the nanoscale, Aspha-Min.

Zeolites are nanoporous crystalline alumino-silicates with important attributes. A zeolite is a constituent of a group of commercially valuable minerals – metamorphosed crystals of hydrated aluminum silicates – of interest to industry for a variety of applications. Zeolites have large vacant spaces or cages in their structures that allow space for large, positively charged ions such as sodium and potassium, and even entire molecules such as water.

Aspha-Min is a synthetic zeolite compound, which releases water (H20) into the asphalt mix to improve workability at lower temperatures. Aspha-Min is available as a very fine, white-powdered form in bags or in bulk for silos. The percentage of water held by the zeolite is 21 percent by mass and is released in the temperature range of 212 to 392 degrees F.

By adding 0.3-percent Aspha-Min to the preheated mixture of sand and stone at the same time liquid asphalt is being introduced, a water-based vapor is created. The water released from the crystal causes the binder to expand to a kind of foam, permitting better workability and coating of aggregates at lower temperatures. Tests indicate that 54 degrees F reduction in temperature equates to a 30-percent reduction in fuel energy consumption.

Thanks for the MEMS

Nanotechnology for transportation infrastructure goes beyond engineered materials, into appliances manufactured at the nanoscale. These nanotechnology-driven sensors and instruments – microelectronic and mechanical systems, also called microelectromechanical systems (MEMS) – have the ability to detect motion and monitor corrosion, cracking and performance of structures and pavements under service loads and conditions.

In their 2008 paper, Applicability of Microelectronic and Mechanical Systems (MEMS) for Transportation Infrastructure Management, investigators Kelvin C.P. Wang and Qiang Li, Department of Civil Engineering, University of Arkansas-Fayetteville, describe the application of MEMS for pavements and bridges.

“With the tremendous advancement in technology, it is possible to employ devices embedded in structural members for real-time monitoring of infrastructure health,” they say. “Micro-electromechanical systems are miniature sensing or actuating devices [that] can interact with their environment to either obtain information or alter it. With remote query capability, it appears such devices can therefore be embedded in structures to monitor distresses such as cracking.”

MEMS merge the functions of sensing and actuating with computation and communication to locally control physical parameter at the micro-scale, yet cause effects at much grander scales, they observe. MEMS as devices have static or movable components with some dimensions on the scale of a micrometer, and can be either sensors, actuators or passive structures.

“Sensors are transducers that convert mechanical, thermal or other forms of energy into electrical energy; actuators do the exact opposite,” Wang and Li write. “Passive structures are devices in which no transducing occurs. A fourth classification, hybrid systems, is used for specialized applications. Micromachining and integrated circuit technologies are the foundation of sensors and actuators as well as of MEMS or microsystems.”

MEMS produce smart materials and structures technology, and their applications include structural control, condition or health monitoring, damage assessment, structural repair, integrity assessment and more recently in asset management, preservation and operation of civil infrastructure, they write. “The potential benefit here is improved system reliability, longevity, enhanced system performance, improved safety against natural hazards and vibrations, and a reduction in lifecycle cost in operating and managing the infrastructure. There is no doubt MEMS can . . . assist engineers in infrastructure management to have real-time or quasi-real-time information on the health of the infrastructure.”

In bridges, MEMS technologies are well-suited to improve the performance, size and cost of sensing systems, they say. “MEMS can be used in both monitoring and testing of transportation infrastructure systems,” they write, adding applications in bridge engineering are underway.

In pavements, MEMS have the capability of supplementing, if not replacing, nondestructive testing of pavement condition, they suggest. “Recently, vigorous efforts have been devoted into developing sensing technologies and nano-technology in infrastructure condition monitoring,” write Wang and Li. For crack monitoring purposes, a MEMS transducer has been developed for an ultrasonic flaw detection system, which can be used to detect the initiation of a crack.

Geometrically smaller size of nanoparticles increases the relative surface area available to react with cement in concrete.

Geometrically smaller size of nanoparticles increases the relative surface area available to react with cement in concrete.Also, networks of nanosensors embedded in roadways could provide real-time information to better manage congestion and incidents, or to detect and warn drivers about fast-changing environmental conditions such as fog and ice. “In recent years, more and more attention has been paid to MEMS-based moisture sensors,” they write. It’s clear that MEMS will play a big role in the intelligent highway systems of the future.

Nanotechnology is leading to self-cleansing signs. The so-called “lotus effect” – which describes the self-cleansing surface of the lotus leaf, which takes place at the molecular level – is being replicated in lotus effect-based self-cleansing nano materials into traffic and work zone signage, and in particular traffic-control devices, which require labor-intensive periodic washing to remove road grime and enhance visibility.

Cleaner air from pavements: Titanium dioxide nanoparticles in both concrete and asphalt pavement surfaces have the ability to remove – via photocatalytic reaction – nitrogen oxides and sulfur dioxide from the atmosphere.

Cleaner air from pavements: Titanium dioxide nanoparticles in both concrete and asphalt pavement surfaces have the ability to remove – via photocatalytic reaction – nitrogen oxides and sulfur dioxide from the atmosphere.“On a hydrophobic, easy-clean surface, particles of dirt are just moved around by moving water, but on a lotus-effect surface, dirt and grime are collected by water drops and rinse off,” Wang and Li write. “Coatings that mimic the properties of the lotus leaf may well lead to signs that shed dirt and never need washing.”

Thin Film Technologies

Nanoscale research could lead to an increased use of recycled materials in pavements through a better understanding of bonding of different materials, and the design of very thin coatings to optimize use of reclaimed materials.

In their 2010 Transportation Research Board paper, New Possibilities and Future Pathways of Nanoporous Thin Film Technology to Improve Concrete Performance, Jose F. Muñoz of the Department of Material Science and Engineering, University of Wisconsin–Madison, and Richard C. Meininger and Jack Youtcheff of the Pavement Materials and Construction Team at FHWA’s Turner-Fairbank Highway Research Center, find that nanoporous thin films (NPTFs) may improve the interfaces between aggregate and cement paste.

“Aggregates are often considered as inexpensive inert filler material in concrete,” the authors write. “However, the mixture of the aggregate with the cement paste creates one of the most vulnerable areas of concrete, the interface of aggregate and cement paste. The judicious application of nanoporous thin films on the aggregate’s surface is an effective way to improve those interfaces.”

The most recent work on concrete shows that the use of different types of NPTF can induce changes in different properties of concrete or in an aggregate’s mineralogy, the researchers say. The observed improvements in mechanical properties such as compressive, flexural and tensile strengths, modulus of elasticity and drying shrinkage can ameliorate longitudinal and transverse cracking, corner breaks, punchouts and D-cracking, they write.

Improving Traffic Safety

Nanotechnology also has a role in improving transportation safety, according to Satish V. Ukkusuri, Ph.D., assistant professor, and Gitakrishnan Ramadurai, graduate student, Rensselaer Polytechnic Institute, in their 2009 TRB paper, A Comprehensive Review of Emerging Technologies for Congestion Reduction and Safety.

Looking ahead 20 years, the researchers identified future technologies, and focused on nanotechnology, as well as other emerging fields. “Nanosensors have potential to track bioterror agents, stress in materials and detect polluting agents in the atmosphere and tailpipes,” they say. “Nanosensors could be used in transportation to monitor pavement conditions, bridge conditions, pollution deduction, bioterror agent detection and air-quality monitoring.”

The feasibility of “cyberliths,” or “smart aggregates,” as wireless sensors embedded in concrete or soil is being studied. Researchers at Johns Hopkins University’s Applied Physics Laboratory have developed a robust wireless-embedded sensor, suitable for long-term field monitoring of corrosion in rebar, particularly in bridge decks, they say.

“Nanomaterials that are of interest in transportation include carbon fibers that are 100 times stronger than steel, nanocoating of metallic surfaces to prevent corrosion, and nano reinforcements in vehicle bodies, pavements and other transportation infrastructure,” Ukkusuri and Ramadurai write. “Automatic healing materials have potential to be used in guardrails that heal themselves, or concrete or asphalt that heal their own cracking.”

Road Science Tutorial

Nanotechnology Will Transform Infrastructure Will Impact Materials, Monitoring, Maintenance, Safety and Durability