Cat’s new S3050 mobile shears in a scrap application.

Cat’s new S3050 mobile shears in a scrap application.Caterpillar has launched two new series of mobile shears that the company says make more cuts per hour than the models they replace: the S340B, S365C and S385C.

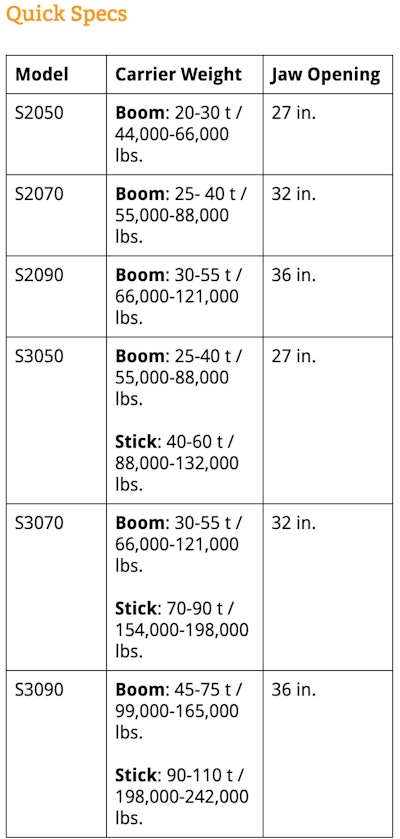

Designed for hydraulic excavators working in scrap and demolition applications, the new models include the S2050, S2070, S2090, S3050, S3070 and S3090. The S2000 Series models are straight configurations while the S3000 Series models are 360-degree rotating configurations. You can view the specs on each new model in the chart below.

All six new models can be boom or stick mounted and feature an improved design with a dual offset apex jaw that Cat says has increased cutting performance and efficiency. The cutting strength has also increased on these new shears, especially when cutting profiles, thanks to the apex design and larger jaw opening.

Cat has also added a new patent-pending bolt-on piercing tip to the upper jaw. In addition to increasing productivity when piercing is required, Cat says this implement protects the moving jaw while reducing wear as it travels through the lower jaw.

The shears’ reverse cylinder is fully protected and has a low profile for better visibility and maneuverability in tight spaces. Meanwhile, the knives and guide blades have four cutting surfaces each and can be rotated before replacement is necessary.

Cat says customers can expect longer overall life on these shears thanks to their alloy steel construction that has a hardness rating “substantially greater than T1 type steel.”