[imagebrowser id=233]

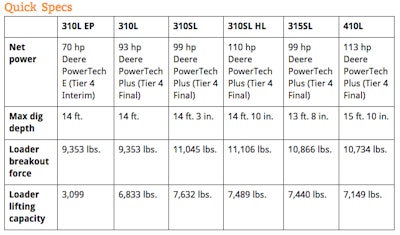

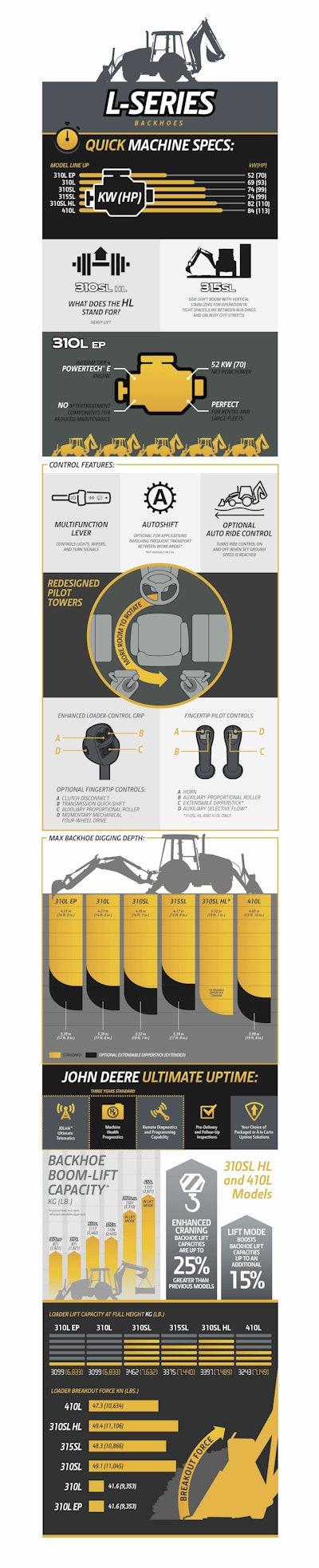

The new John Deere L Series backhoes, ranging from the 70-horsepower Tier 4 Interim 310L EP to the 113-horsepower Tier 4 Final 410L, include two Heavy Lift models that boost backhoe lift by up to 40 percent. (See QuickSpec chart below for an at-a-glance overview of the new models.)

The 310SL HL and the 410SL models offer Deere’s new Heavy Lift feature.

Using pressure compensated load sensing (PCLS) hydraulics, a revised rear backhoe valve, improved rear structures and larger cylinders on the backhoe boom, these models can lift up to 25 percent more than their K Series predecessors. In addition, a new Lift Mode feature gives operators the ability to get an additional 10 to 15 percent boost, making possible a total of up to 40 percent more lifting power.

The Lift Mode automatically sets the engine rpms at 1,400, which gives the backhoe the capability of maximizing hydraulic pressure for the lifting operation.

The largest L Series introduction, the 15-foot 10 inch dig depth 410L also has Deere’s new Heavy Lift and Lift Mode features, which offer up to a total of 40 percent more backhoe lift capacity.

The largest L Series introduction, the 15-foot 10 inch dig depth 410L also has Deere’s new Heavy Lift and Lift Mode features, which offer up to a total of 40 percent more backhoe lift capacity.“Although Deere’s basic PowerCurve boom is still the same design, we strengthened the boom and enlarged the cylinders” to achieve Heavy Lift, says Brian Hennings, Deere backhoe product manager, during a press event yesterday at Deere’s Sacaton, Arizona, proving grounds.

Inside the cab, the L Series upgrades include a new seat and increased legroom to ease the seat transition between the loader and backhoe ends. The redesigned pilot control backhoe joystick towers use fingertip electrohydraulic controls.

On the loader end, a new palm-on-top loader lever on the right allows you to control the clutch disconnect, quick shift, auxiliary proportional roller (for using a multipurpose bucket) and engage a momentary front wheel drive that can be used on the fly. “The clutch cut out really comes in handy when loading trucks,” Hennings says. “It lets the engine rev up as you dump the load and releases when you no longer need it.”

The in-cab monitor shows machine diagnostics and controls, and allows operators to program functions such as auto idle and auto shutdown. L Series owners can opt for John Deere’s Ultimate Uptime program, which includes the John Deere WorkSite suite of programs: JDLink machine monitoring system, machine health prognostics and remote diagnostics and programing.

Other operator-centric features include lower and larger steps to get in and out of the machine, an efficient HVAC system and an elevated canopy for better visibility around the cab.

Five of the six new models use Tier 4 Final Deere PowerTech Plus engines, and require diesel emission fluid. The exception is the 70-horsepower 310L EP, which remains at Tier 4 Interim. In addition, the 310SL, 310SL HL, 315SL and 410L have a five-speed PowerShift transmission offering clutchless gear changes and speeds up to 25 miles per hour. The Autoshift option automatically selects the best gear for the load, and offers fuel efficiency gains.

Deere now offers a side shift model, using an H-carriage that allows the backhoe to be easily repositioned in tight quarter situations.

Deere now offers a side shift model, using an H-carriage that allows the backhoe to be easily repositioned in tight quarter situations.Sideshift 315SL designed for tight spaces

Deere says the 315L sideshift backhoe model reintroduces the company to this niche machine. Although sideshift models, which allow the backhoe end to be repositioned along a sliding H-frame carriage, are preferred in Europe, they’ve never gained much market share in the states, where contractors overwhelming choose center mount backhoes. Deere thinks contractors in several applications should reconsider the sideshift mount. “It gives you access to tight areas, since the H-frame allows you to work in areas that traditional center mounts can’t get into,” Brian says.

To use the sideshift feature on the 315SL, position the backhoe at a 90 -degree angle left or right of the machine in the direction you want the backhoe to go, put the bucket teeth down in the ground, press a foot pedal in the center of the floor area and curl the bucket. The backhoe then slides along the horizontal carriage and locks into the new position. In addition to allowing the backhoe to reposition horizontally, letting you dig up against a wall or other obstacle, the H-frame stabilizers move vertically up and down, and thus don’t require as much space as conventional stabilizers when extended.