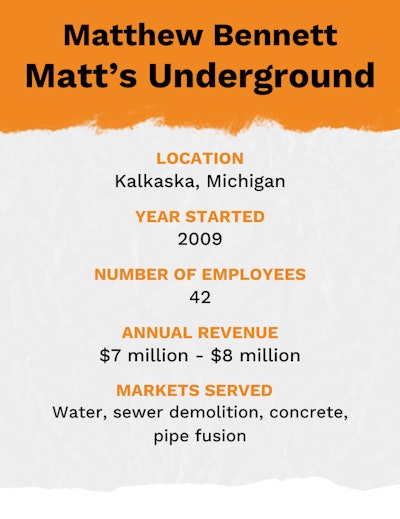

Matt Bennett, founder of Matt’s Underground in Kalkaska, Michigan, believes in the power of two things when it comes to construction: diversifying the company and doing as much as possible yourself.

Those beliefs, built on over 20 years of experience, have served the company well and made it a finalist for Equipment World’s 2025 Contractor of the Year award. In addition to its drilling and excavation departments, Matt’s Underground has built one of the largest pipe fusion businesses in the Midwest, with a reputation strong enough to gain clients around the country.

Matt's Underground offices in Kalkaska, Michigan.Equipment World

Matt's Underground offices in Kalkaska, Michigan.Equipment World

Matt’s Underground has additionally brought many secondary tasks in-house, evident in the size and output of its on-site service and fabrication shop.

20 Years of Two Brothers-in-Law

Bennett’s brother-in-law, Isaac Belongia, is the company’s project manager, taking care of scheduling, pricing, bids and most daily operations. Bennett views his role primarily as supporting Belongia and dealing with whatever is the “hottest ticket of the day.” Bennett also oversees the company’s shop and asset acquisitions.

Matt Bennett (right) and his brother-in-law Isaac Belongia have worked together for over 20 years.Equipment World

Matt Bennett (right) and his brother-in-law Isaac Belongia have worked together for over 20 years.Equipment World

The pair’s 20-year working relationship plays on their opposite personalities. Bennett says he thrives in high-stress environments. Belongia, on the other hand, controls the chaos of the day and contributes the organizational skills that balance out the company.

Bennet likes to run a 3-to-1 ratio on field to office employees. This means for ever three workers out generating revenue, there’s one person working in the office or shop.

“There's a lot of behind-the-scenes resources it takes to do it correctly,” he says. “Some contractors in comparison to our size have different business profiles or makeups, and they don't necessarily have as many office staff as us. But we found that this works, and this is what it takes to actually do it to the standard that we're held to.”

The second story of Matt’s Underground is devoted to staff enrichment and comfort. Employees returning from the field can shower off the day’s dirt, wash their clothes in the laundry and change in the locker room. Bennett says they regularly give seminars and training sessions in the adjoining lunchroom as part of safety and compliance.

Learning the Ropes … or Pipes

Bennett’s construction career started as a mechanic at a pipeline company. He’d gone to college for a semester then dropped out, referring to it as “the most miserable thing I’ve ever done in my life.” He didn’t want to sit and ponder; he wanted to be on a team and solve problems in a dynamic environment.

He’d planned on and begun training to be a mechanic while in high school and had worked as a teenager servicing trucks for sanitation and school bus companies. But it was through this job working on trucks and equipment at the pipeline company that he learned the skills for his eventual construction career.

Bennett explains the physics of pipe fusion next to a McElroy 618 fusion machine.Equipment World

Bennett explains the physics of pipe fusion next to a McElroy 618 fusion machine.Equipment World

“I went to work there as a mechanic and learned how to fuse pipe, run a side boom, learn how to excavate, run equipment, drive a truck,” he says. “That being said, I didn't see it coming. I didn't know that pipelines or pipe installation was going to be in my future. It was just something I knew how to do.”

That company eventually downsized, and, as one of the remaining employees, Bennett earned his stripes and built his work ethic, putting in long hours doing whatever needed to be done.

After that, what started as doing odd jobs in the area grew to a small residential construction business with Belongia, who had recently married Bennett’s wife’s younger sister.

After Hurricane Katrina hit the U.S. in 2005, the pair headed south to link up with another contractor on more residential and disaster recovery jobs in Mississippi for nine months. Upon returning to Kalkaska, they worked for a few years for other companies using the experience they’d gained in excavation, including work in environmental cleanup and installing landfill liners.

Eventually, the two decided they preferred to work for themselves. So, they started over again from the cab of their pickup, and Matt’s Underground was born in 2009.

Why Control Matters

The housing market crash around the same time played a part in the decision to start over and influenced their desire to have more control over their work then and today. The impact of those difficult times and not getting paid left a lasting impression on their business plans and pushed them to diversify.

Bennett and Belongia lay a sewer line in Mancelona, Michigan, in 2011.Matt Bennett

Bennett and Belongia lay a sewer line in Mancelona, Michigan, in 2011.Matt Bennett

“We didn't have a lot of extra money to do anything, every penny counted,” says Bennett. “... There were several times when we didn't get paid, and it was crushing.

“I get up every day still, probably not as much as I did then, but saying to myself, ‘We're never going to be back in the corner again.’”

Pipe Fusion: Success in a Niche Market

The core of Matt’s Underground’s business is pipe fusion. The company offers fusion for high-density polyethylene irrigation pipe from half an inch all the way up to 72-inch outside diameter.

Bennett and Belongia’s connection to pipe fusion goes back 20 years to their early days in construction together, doing excavation work out of a pickup truck. After one customer asked if they’d also do small pipe fusion, Bennet paid a few hundred dollars for a small machine, cleaned it in his garage and paired it with a generator he dug out of a junk pile. Bennett says that first machine, which can only fuse 1- to 4-inch pipe, is still a functioning part of their fleet.

Matt's Underground pipe fusion machines.Equipment World

Matt's Underground pipe fusion machines.Equipment World

Their fusion machine fleet is approaching 160 units, and Bennett says they’re one of the largest pipe fusion contractors in the Midwest. Their largest fusion machine is a McElroy T900, capable of fusing pipe up to 36 inches and one of just a handful in the state of Michigan.

Key pipe fusion customers include industrial processing facilities, oil refineries, power plants and chemical plants. The scopes of the irrigation systems vary, with some made to be used for just six months and others for several years.

The strength of their reputation in the pipe fusion world has Bennett working jobs across the U.S., as far as Corpus Christi, Texas.

Rebuild & Refurbish

Bennett is a big believer in keeping up with the latest advancements in construction tech. For example, during his on-site visit and interview as a Contractor of the Year finalist, a Hilti USA sales rep visited one of the company’s jobsites to demo a new manhole coring system Bennett had just purchased.

It’s obvious from the yard of beat-up trucks behind the shop that Matt’s Underground believes in reusing and recycling machines before buying a new one. Among the vehicles staged for various projects out back include old busses and a decommissioned Detroit Fire Department ambulance. Many of these will be stripped to the chassis and welded together, turning two old vehicles into one.

Multiple former ambulances wait behind the shop to be used in future projects.Equipment World

Multiple former ambulances wait behind the shop to be used in future projects.Equipment World

Bennett says this habit came in handy during the pandemic. When truck parts were hard to get, their shop already had the process for scavenging and piecing vehicles together.

They do the majority of their repairs, having invested in a well-equipped shop and skilled technicians, saving downtime by not depending much on outside mechanics.

This mentality also applies to their pipe fusion machines, which Bennett says they buy at auction from gas and power companies then repair themselves.

Growing from Within

Bennett says the company has reached a comfortable size and has no interest in growing bigger, which would require more management and a whole new tier of assets. Instead, the goal is to refine what’s already in place and grow profits with greater efficiency.

“Our growth strategy is to get better from within,” he says. “It makes money. It's profitable. We want to shave waste and become more efficient and be better at our jobs.”

Compacting backfill with a BOMAG BT65 TamperEquipment World

Compacting backfill with a BOMAG BT65 TamperEquipment World

Part of reaching that goal involves services Matt’s Underground has brought in-house. They perform their own dewatering, trench shoring, fabrication, sheet piling, hydro mulching, slope stabilization and more.

“Not only can we control the schedule, but we can we span the dips in the market,” Bennett says. “And so that diversity and that ability to self-perform all these different tasks makes us valuable to small entities like the Village of Kalkaska.”