Oneal Lindler knew at a young age he wanted to own a business and was always fascinated by heavy equipment.

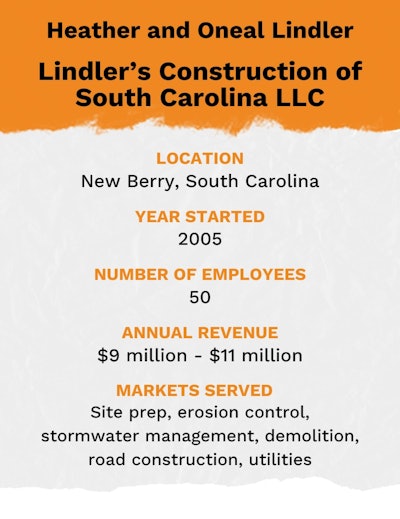

Oneal and Heather began dating after high school and married. Together, they incorporated Lindler’s Construction of South Carolina in 2005. She got her contractor’s license and ran the office, and he ran equipment and the jobs in the field. They both are self-taught, adding new skills and licenses to expand the business at a steady pace.

Today, they have 50 employees and perform road construction, site prep, storm drainage and demolition. They have worked on major interstate projects, as well as for county and municipal governments in their area. They also perform emergency work for the South Carolina Department of Transportation.

Both Heather and Oneal work long hours and are dedicated to growing the business. They also strive for efficiency, with 2024 being their most profitable year yet – without adding new employees.

For that reason and more Lindler’s Construction is a finalist for Equipment World’s 2024 Contractor of the Year.

Learning the Business

Heather and Oneal Lindler started Lindler's Construction of South Carolina in 2005. Equipment World

Heather and Oneal Lindler started Lindler's Construction of South Carolina in 2005. Equipment World

Oneal began clearing residential lots and doing building pads right out of high school. “Then I moved up to building fishponds and duck ponds and roads through large tracts of land,” he says.

He bought his first excavator at 17, a used machine. When he was 18, a salesman from Blanchard Cat spotted Oneal on a jobsite and stopped to talk. Oneal filled out a credit application on the spot to buy a new Cat 320 excavator.

The company landed sub work with United Constructors on the I-520 bypass in Aiken County for about five years grading bridge approaches and clearing.

They accumulated more equipment – dozers, dump trucks, lowboys.

“We move our own equipment,” Oneal says. “We started moving equipment for other people.

“We hauled our materials. We started hauling for other people. And things progressed.

“Heather has a lot to do with that.”

Heather handles all the payroll, the accounting, time tracking for the workers. The company started its own hauling department, and she oversees that, dispatching drivers, hiring and firing.

“I was blessed with knowing how to get a job done, and she was blessed with her smarts,” Oneal says. “It would take four people to do what she does.”

Neither Oneal nor Heather came from a construction background. They both say they had good mentors along the way, particularly with United Constructors. “I got taught by the best,” Oneal says. “I went above and beyond whatever I had to do.”

"Slow and Steady"

Lindler's Construction crews on roadwork in Saluda County.Lindler's Construction of South Carolina

Lindler's Construction crews on roadwork in Saluda County.Lindler's Construction of South Carolina

“Growth has been slow and steady,” says Heather. And they like it that way.

“Over the past three years, we've kind of leveled out,” she says. “This is where we are the most manageable, because Oneal and I are very much involved in the day-to-day operations. When you get much more than that, you have to rely on so many people – not that we can't – but you're not as in tune with everything that's going on. And I think that's helped our success.”

The company’s most profitable year, so far, was in 2024. And they had the same number of employees as they did in 2023.

Efficiency is a top priority because most of their projects are with municipal and county governments and require lowest-bid contracts.

“Of the projects we do, we’ve got to be the low bid,” Oneal says. “And in order to be low bid, you’ve got to get out here and figure out how to get it done quicker than the competition and more efficient.”

That approach has also made for happy customers.

“I’ve been impressed every time I’ve worked with them,” says Derrick Pratt, Lexington County state road-fund project manager. “Anytime there’s a low bid on a job, we don’t have to worry. We’re in good hands with them.”

That added efficiency includes GPS machine control on dozers and motor graders.

“I was not a big fan of it at all when it first got brought to my attention in the early 2000s,” Oneal says, “but once we started to run it, it is a necessity. It cuts a lot of moving the same dirt twice.”

Willing to Wait for Good Employees

Along with roadbuilding, Lindler's Construction performs complex drainage improvements.Lindler's Construction of South Caorlina

Along with roadbuilding, Lindler's Construction performs complex drainage improvements.Lindler's Construction of South Caorlina

“We have lots of applicants. That part is not the issue,” she says.

She looks for candidates who will stay with the company, and she’s willing to wait. The company has a dump truck that’s been sitting for eight months. “It's going to sit until I find somebody that'll be here for a while,” she explains.

The company prefers to train its own workers. “We've had a lot of success hiring young guys that have pretty much zero experience and training them,” she says.

They start on a crew with a shovel, then they learn to operate equipment. One worker started with the company when he was 17 and is now leading a crew at 25.

They’ve tried a variety of methods to attract new hires, but only one seems to work.

“We have tried advertising, third parties, social media,” Heather says, “and the best have always just been word of mouth.”

Immaculate Equipment

Lindler's Construction believes in keeping its equipment clean, including its service trucks.Equipment World

Lindler's Construction believes in keeping its equipment clean, including its service trucks.Equipment World

“I’ve known Oneal and Heather for about 20-plus years. It has been a pleasure watching them grow their business,” says Mike Hanley, construction operations manager at CR Jackson Inc. “He has helped me from the beginning with punch-list work to now taking on sections of work on large interstate projects.”

Heather lists the company’s knowledgeable staff as a large part of the company’s success. They also strive to find issues before they arise on a project and figure out how to manage them before they become a problem.

“We get compliments on this all the time; we have immaculate housekeeping,” she adds.

“Whether it's the shop or the grounds or our equipment, we've gotten excellent, rave reviews on that.”

“It seems so small,” she adds, “but it sets the tone for who we are as a company.”

Oneal puts it more bluntly on why he only keeps topnotch, spotless equipment:

“I don’t want junk. I ran junk for years. We're not running junk no more.”

The company also carries little debt, with only about two of its 60 pieces of heavy machinery financed.

“We've got it in our software what the machine needs to make per hour for the company to save money,” Oneal explains. “So whenever it's time to buy a new one, the company has the money to buy the new one.”

Looking back on their early days, Oneal and Heather are proud of the company they’ve built from scratch over the past 20 years.

Oneal also makes a point to praise Heather for her management skills and their successful partnership.

“I knew I had a dream, and I knew I could make it,” he says, “and if something would have happened, as far as Heather wouldn't have been my wife, this would have never worked out.”