Although Jeremy Hiltz started his own company in 1996, his roots in construction go much deeper. When he was just five years old he would get up early, creep downstairs, grab his lunch pail and wait for his dad by the door, hoping to get a ride to the jobsite.

“I was pretty low maintenance,” Hiltz says, “just happy to go.” By the time he was 11, Hiltz was running a wheel loader for his dad and working every hour that school didn’t claim for the family excavation and site work business.

When Hiltz ventured out on his own in 1996, all he owned was a pickup truck. He got one job, demo’ed three different excavators to complete the job and used the money he earned as a down payment on the one he liked the best. Hiltz and his small crew worked 20 hour days to build up enough cash to purchase additional equipment and by the end of his first year he’d banked $500,000 in sales. The second year, he doubled that and it was off to the races.

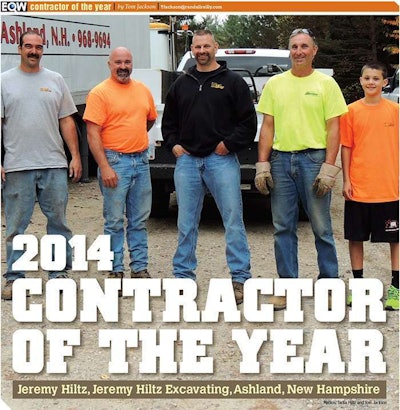

Today more than 20 people from his dad’s old company work with Jeremy including office manager Karen Nichols, who has worked with Jeremy since he was 17. “We call them the alumni,” says Hiltz. “We’re like a family here. There is no pecking order; everybody is the same, laborer or engineer. Each is equally important and we all wear many hats,” he says.

Growing during the recession

The recession hit Hiltz Excavating just like every construction company. Although his margins shrank, the business was solid enough to continue to grow and Hiltz didn’t have to lay anybody off.

“It was tough,” Hiltz admits. “We were lucky to get some school work. We went into that sector hard and were lucky to stay busy.”

Finding the right size for his company was also a challenge. “We’re not a large company, but we’re not a small company either,” Hiltz says. “Being medium sized brings the kind of overhead a small contractor doesn’t face, yet we didn’t have enough horsepower to punch the big guy in the chin. We did well, but not as well.”

Which way to go? Hiltz chose growth and after about a year, the success he had been enjoying came back.

“We just looked harder at how to build the mousetrap,” Hiltz says. “We’ve

Bankable reputation

But success at Hiltz Excavating is as much about reputation as it is efficiency and right-sizing. “We have always been adamant about paying our bills,” Hiltz says. “We may not get paid, but it is important to us to keep our subs and vendors. Our credit is impeccable, so our bonding has always stayed strong. In fact, many private projects require bonding in the pre-bid, but if the owner knows us, they will elect not to bond the project because it saves them thousands of dollars.”

Andy Davis can testify to the company’s reputation. Davis spotted one of Hiltz’s spit-shined dump trucks while driving one day. He was so impressed that he looked up the telephone number and asked to see the head of the company, eventually becoming Hiltz’s insurance agent.

“Other contractors get frustrated when they see him at a pre-bid because they know he does great work,” Davis says. “He’s out there in the trenches with the troops, working alongside his employees, making sure everything is perfect. He genuinely cares about the people who work for him. All of his employees take pride in the company.”

Old school skills

Having grown up around equipment, Hiltz and many on his crew have developed a level of skill and craftsmanship that few can match. “Even with all the changes through the years, we can look at an application and still do something old school,” he says. “Sometimes that’s going to be faster and more efficient.”

For example he says: “Today everybody does everything with an excavator and a clean-up bucket. But we used to clean up with a dozer. We’re not so dependent on the excavator. We can throw in a small dozer and clean up a roadside and we have the operators who know how to do it.”

Hiltz is fanatic about productivity. Whereas a typical operator might load a truck every minute and a half, Hiltz coaches his guys on technique until they can get it down to 45 seconds.

“To load a truck fast, you don’t load it,” Hiltz says. “You are basically throwing the dirt in the truck, but in a smooth manner. It’s something you have to practice. Don’t wait for the truck to stop. Blow the horn while he’s still backing up. Then everybody gets into the whole production. You get geared up and make it a challenge—how many loads did we get today?”

Hiltz cautions that it has to be coaching, however, and not criticism. “It’s one-on-one. You show them the dollars and cents. That way nobody feels demeaned,” he says.

Keep it clean

At the end of every shift, the company’s operators and drivers are expected to clean out the cab, dusty surfaces are wiped down and the dash gets a hit of Armor All. Seats are protected with seat covers and nothing is allowed on the dashboard. Metal lunch boxes are not allowed either as they can scratch dash and console materials. “If you don’t have a soft-sided lunch box, I will buy you one,” Hiltz says.

Hiltz doesn’t discriminate against smokers, but says smoking is not allowed in his machines or trucks. “It’s unfair to those who don’t smoke if they have to get into a machine that reeks of tobacco and they have to work in it for 12 or 13 hours. People can smoke on their breaks, they can chew all they want, but they can’t smoke in the equipment.”

When operators or drivers come back to the yard, they pressure wash their machine or truck. Everything is waxed on a regular basis. This brings two benefits: One, it sets the tone for company. It gives the crews pride in the machines they operate and the work they do. Two, nobody has to work in a ratted-out machine.

The other benefit to keeping his trucks and equipment in mint condition is that Hiltz can get top dollar for them at auction. And Hiltz turns over his fleet quite often, sometimes keeping key machines as little as three years.

Early GPS fan

While old school earthmoving methods have served the company well, Hiltz is also an enthusiastic fan of GPS technology.

An early adopter of laser systems, Hiltz bid on a job with 20 acres of athletic fields about six years ago, and decided to take a gamble on GPS. “The fields were super-elevated and crowned and you had to do it in three of four layers, and every layer has a tight tolerance,” he says. “With the old school method you would have to stake this in a 15- or 25-foot grid with stringing in-between. A grade crew would have to be constantly checking to make sure your tolerances were on.”

GPS took the staking away and all the trial and error that went with it. “With GPS, the tolerance was about a tenth, and that’s not fine enough,” he says. “However it’s close enough that the laser box can grade it to within the thickness of a dime and they can follow the GPS machine and work in tandem. We breeze through these things now and have never once failed a grade check.”

Hiltz hesitates to guestimate how much more efficient his crews are with GPS, but he says it’s probably around 25 percent.

Safety first

Hiltz Excavating has once-a-week toolbox talks on safety. The most common topic, not surprisingly, is trenches and trenching. “An important part of our safety program is making sure all the equipment is in good working order,” Hiltz says. “Lifting gear is the most important, but being certain each job is equipped with the proper gear is also a top priority. If we have an issue we’ll shut down and talk to everybody about it.

“The safety program gets us rebates on insurance for having a good safety record, and it’s important to our general contractors and clients,” Hiltz says. “It didn’t used to be, but now its one of the premises on which you get hired.”

Staying humble

Jeremy learned how to run equipment and jobs working alongside his dad. But the most important lesson he learned from his dad is to be humble. “Being humble means not living outside your means, putting your money back into the company,” he says.

“When he’d see other contractors with big boats or expensive sports cars, my dad would tell me, ‘Son, that’s all fine and well, but if you have a good year, put it back into the company, because next year you may not have such a good year; or give the guys a bonus for working hard,’” Hiltz says.

Competitive spirit

The similarities between construction contracting and sports are many. And like many contractors, Hiltz played sports in high school.

As an adult, Hiltz stays committed to a healthy lifestyle, exercising on a regular basis. Using boxing as a routine part of his workout, Hiltz’ coach Greg Avila commented on his ability in the ring and suggested he take it seriously.

At his age Hiltz doubted he could compete in boxing, but it had been an interest of his for quite some time. The Vermont Golden Gloves has a tournament every year where they hold a Masters Division, and his coach suggested they work towards that.

They trained daily on top of a typical work day. Hiltz’ coach knew Dicky Eklund, a pro boxer/trainer who was in the movie “The Fighter,” filmed in Lowell, Massachusetts. He knew learning from Eklund would be a great benefit to Jeremy so they started doubling up his training sessions, going to the West End Gym in Lowell Massachusetts on a regular basis.

Hiltz trained for four months leading up to the fight in January. During this time, he sustained broken ribs twice while sparring. After the fact, Eklund was astounded at the fact that Hiltz didn’t stop him. “Even my pros stop me after a minute,” Eklund says. “Hiltz never said a word even after six, three-minute rounds.” There was considerable healing time needed, which did interfere in his training. To make matters worse, just as the ribs healed Hiltz got pneumonia. Luckily, Hiltz was able to shake that just in time for his Vermont Golden Gloves match.

At the fight the only available opponent for Hiltz, who had been training as a heavyweight, was the super heavyweight defending champ – 100 pounds heavier, with a 6-inch advantage in reach and height.

Despite the disadvantage, Hiltz’s competitive spirit wouldn’t allow him to decline the match. He hung in for three rounds and was scoring well when a blow to the back of the head caused his legs to wobble. The referee would not allow the match to continue.

Nonetheless, Hiltz was thrilled to have the opportunity to box against a great fighter and bring to the boxing ring the same dedication and focus that have made his construction company a success.