Cat designed its new MH3250 and MH3620 tracked material handlers to reduce owning and operating costs by 20% from their predecessors, the company says.

Cat achieves the lower O&O costs by increasing fuel efficiency and maintenance intervals, among other improvements.

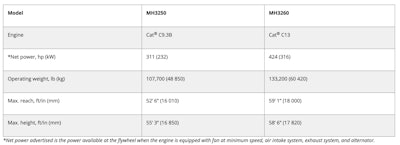

The models, which also come with a new cab concept, replace the 330D MH and 345 C MH. Lift height is 52.5 feet for the MH3250, and 59 feet 1 inch for the MH3260. Operating weight is 107,700 pounds for the MH3250, and 133,200 pounds for the MH3260.

Both machines have new Cat Tier 4 Final diesel engines that can run up to 20% biodiesel fuel. The MH3250 delivers 311 net horsepower and the MH3260 produces 424.

Three different power modes can match performance to the task:

- Smart Mode automatically applies engine and hydraulic power to working conditions to reduce fuel consumption, Cat says.

- Power Mode is for max productivity.

- Eco Mode helps save fuel during less demanding tasks.

For the operator, Cat recreated the cab, making it quieter with sound suppression. It sits upon rubber mounts to reduce vibration. It also features an air-suspension seat that is heated and ventilated. Keyless push start is also standard. Controls are in front of the operator within close reach. The left-hand console tilts up to make it easier to get in and out of the cab.

The 10-inch high-resolution touchscreen uses a jog dial-control. The screen also shows views from the standard side and rear cameras. Operators can set their joystick and power mode preferences with the Operator ID function, and those parameters will return automatically when the ID is typed in.

Design changes improve operator visibility, such as smaller cab pillars, large tempered windows and a flat engine hood. The windshields are thick and impact-resistant, meeting P5A glass standards. Operators are protected from falling and flying debris with the standard Falling Object Guard System.

Cat MH3260 Material Handler

Cat MH3260 Material Handler

For improved shredder loading and for loading and unloading highwall trailers, the hydraulically controlled cab can rise as high as 19 feet 9 inches from its lowered height of 11.5 feet. Should there be hydraulic service interruption, the cab can be lowered by emergency valves inside and outside the cab. Check valves on the boom and stick prevent reverse hydraulic oil flow to maintain the position of the front linkage should the hydraulic system experience an unexpected loss in pressure, Cat says.

The material handlers can operate in extreme conditions of up to 125 degrees Fahrenheit and start in temperatures as low as -25 degrees. Auto warmup heats up hydraulic oil faster in cold weather, and a new valve priority automatically places hydraulic pressure and flow where it's required to increase efficiency, according to the company. An advanced electrohydraulic system balances power, efficiency and load control, Cat says.

The machines can operate at up to 8,530 feet above sea level.

To make service less frequent and easier, Cat synchronized service intervals and extended filter replacement schedules. All fuel filters are coordinated to be replaced at 1,000 operating hours. A new air intake filter with pre-cleaner also lasts up to 1,000 hours. The hydraulic oil filter lasts 3,000 hours, 50% longer than previous filter designs, and new anti-drain valves keep the hydraulic oil clean during filter replacement, Cat says. A high-efficiency cooling fan features an automatic reverse function to keep the cores clean.

Cat also made it easier and safer to maintain the material handlers with an upper-level service platform that has access steps constructed of antiskid punch plate. Ports are positioned for taking quick fluid samples, according to the company.

Operators can track filter life and maintenance intervals on the touchscreen. Techs, fleet managers and others can use the Cat App to get maintenance alerts and track fleet location and hours. Cat's Remote Flash automatically updates onboard software without interrupting the production schedule.

The material handlers can operate a variety of Cat Work Tool attachments. The MH3250 can be equipped with the ex-factory 25-kilowatt generator for magnet operation.

Check the Specs