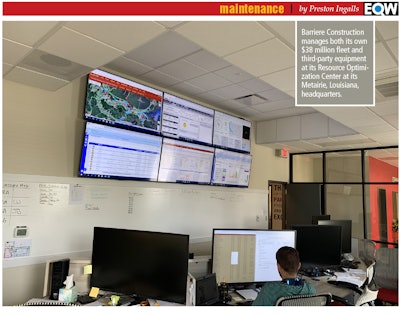

With the help of GPS tracking, in- and out-of-cab video cameras and fleet visibility and scheduling software, Munna leads a team of five reliability coordinators who manage, dispatch, schedule and mobilize all of Barriere’s owned and third-party equipment through its Resource Optimization Center (ROC).

Better resource utilization and increased efficiencies were two of the goals behind Barriere’s combining its logistics and equipment departments to form the ROC in 2018. It didn’t take long to deliver on those goals.

“We already shared all the same equipment [between groups], so it made sense to combine everything,” says Munna, ROC manager. Getting everyone together cut out the back-and-forth of phone calls and emails to confirm every move, and it provided rapid efficiency gains in the overall process. “When you centralize things, it makes life easier,” he says.

Serving the Gulf South with six offices and sites throughout Louisiana, Barriere specializes in heavy civil and highway construction. Established in 1937, the $200 million, 500-employee company has 150 pieces in its $38 million fleet.

The ROC enables Barriere to optimize where its resources are scheduled across the company. The results are no wasted trucks or equipment moves, no equipment left languishing while a job is shut down, and minimal equipment downtime, thanks to an aggressive proactive maintenance program.

“Knowing each team’s goals for the day allows us to optimize the equipment and trucks they’re allocated,” says Ben Tucker, director of equipment and facilities. “We won’t overserve them equipment, and we’re able to identify if they’ve shorted themselves on the trucks they need to meet their budget.”

Starting small

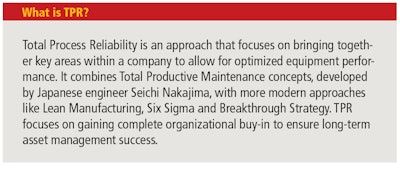

“Working with TBR Strategies put the wheels in motion and guided us to where we are,” notes Tucker. “They helped change our thought process.”

At its North Shore asphalt operations, Barriere hired a logistics manager, helping it quickly lower overall costs and achieve better gross profit through more efficient equipment utilization. In less than two years, the North Shore group saved between $800,000 and $950,000 and shrank the emergency rate to 1 percent of total maintenance hours.

The light bulb went off, and the company’s other two asphalt groups adopted TPR in 2018.

“No one could argue with the data,” says Jason Latiolais, vice president of asphalt operations. “People took notice, and we knew we had to implement it as a global approach.”

Within a year, Barriere integrated its construction group into the ROC. Today, Barriere’s construction and all three asphalt groups share resources through the ROC, which has grown from a three-man team in a cramped trailer to a six-man operation with a dedicated workspace in one of Barriere’s office buildings.

Technology forward

In addition to streamlining communications by bringing its key players together, Barriere prioritized investing in technology.

“Technology has played a big part of it,” Tucker says, “by clearly outlining all our gains in efficiencies.” By leveraging different programs and apps, the ROC team automated and improved many of its daily tasks, going nearly completely paperless in the process.

These are some of the technologies Barriere is using:

B2W: Schedules production crews, maintenance vendors, third-party trucks, owned and rented equipment, and maintenance of on- and off-road equipment

FleetWatcher: Locates trucks and equipment, as well as provides live data reporting to proactively detect any issues.

VisionLink: Caterpilar’s asset monitoring system provides visibility to off-road equipment health, utilization, fuel and hours.

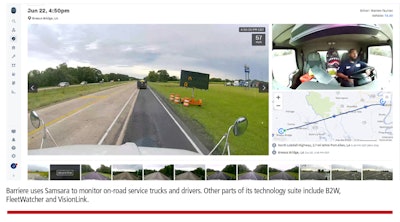

Samsara: Monitors on-road service trucks and drivers and provides safety score cards. It is connected to interior and exterior video equipment that records the driver and the vehicle’s surroundings.

All of this data are archived and accessible, meaning the team has hundreds of past projects to act as reference points, providing it an increasingly precise roadmap for the future. Decisions are based on hard data, making for more accurate end results.

Technology has also provided clear visibility across the company by democratizing data and insights gained. Automated reporting provides a reliable source of truth, helping the team avoid potential disputes due to missing or late paperwork.

“The reporting is more accurate,” says Dylan Varnado, ROC trucking coordinator. He says it’s helped make him much more efficient in his role, especially when it comes to scheduling and payroll. “About 85 percent of our fleet has GPS now. It’s made my job a lot easier to find out how much time it actually worked.”

Maximizing usage and uptime

By housing all of Barriere’s projects and equipment scheduling under one roof, the ROC team can distribute resources more effectively, minimizing project downtime and maximizing equipment usage and uptime.

Equipment is allocated depending on job priorities and needs. If a specific machine isn’t available, the ROC team can assign a replacement based on the needs of the job. This is accomplished through comprehensive reporting to identify gaps and collaborative teamwork to efficiently fill those gaps.

In addition, the automated records’ diagnostics give the team better visibility into equipment maintenance needs, pinpointing specific issues and extending the life of the pieces overall.

“Just getting the paperwork back in a timely manner, we are 100 percent more efficient than we were three years ago,” Munna says. “It’s cut the emergency-maintenance rate down since we’re not waiting days to get paper reports.” It also means the equipment team can schedule repairs before problems occur.

The right people at the right time

The third part of the ROC’s success is its team of coordinators and managers. A key part of the TPR system is the belief that change happens when the right people are working together toward a common goal. That’s why it focuses on implementing cultural change in tandem with process change.

“It’s not just about the ROC, it’s about the people that you put together,” Bradley emphasizes. “You need people who care, who want to see each other and the company succeed. None of this is going to work without the right people.”

A common challenge many companies face is fractured priorities, with teams focusing only on what’s best for them rather than what’s best for the whole company. Barriere had already laid the groundwork by fostering a more collaborative culture, even adopting the motto “One Barriere.” This philosophy change paved the way for more tangible change with the ROC.

The team quickly realized the value of working together in the same room. The benefit of multiple eyes and perspectives and the ability to discuss how to adapt as issues arose was felt almost immediately. There were even fewer disgruntled messages from the field about being shorted on equipment for the day.

During the current COVID-19 disruption, the ROC team has maintained its efficiency and competitive advantage. “To me, the ROC is more of a concept at this point,” Varnado says. “Not being in the same office together every day, we still see and reap the benefits of it. The underlying principles of communication across departments is what’s made the biggest difference.”

Competitive advantage

The success of the ROC has translated into a competitive advantage for Barriere. Its historical data over the past several years have improved bidding accuracy. Barriere says it is winning more bids through competitive timelines and pricing and saving on overages through more precise project planning and management.

“We’re coming in lower on bids, thanks to better insight into equipment and crew availability,” noted Ricky Quigley, general superintendent of operations. “We can intermingle schedules and identify opportunities where groups can help each other, better utilizing our resources, equipment and trucking.”

“The ROC system has fine-tuned our data so we can bid that into the job,” Latiolais adds. He credits the historical data Barriere have captured since the ROC was implemented for the company’s increased bidding accuracy.

Without risk, no reward

By being willing to take a risk and address some of the most common communication roadblocks companies face, Barriere has realized savings across multiple fronts.

“Unless you completely understand the benefits you’re going to get from it, it’s hard to make that decision [to implement change],” Latiolais says. “The easy thing would be going back to the way we’ve been doing it for 50 years. But it’s about the synergies and hidden efficiencies because of what we’re doing with the ROC.”

The initial pilot project with the North Shore asphalt group delivered nearly $1 million in savings accumulated over a year and a half. Since the ROC has been formalized into a global corporate initiative, it’s made room for even more savings, including:

• Reduced equipment downtime and increased longevity of pieces, which eliminated unnecessary equipment purchases.

• Less time to complete work orders, dropping by six and a half days for corrective maintenance and 10 days for service orders.

• Reduced costs by 5 percent in 2019 through visibility benefits for the trucking operations. Those savings have continued to increase this year during the pandemic.

• Provided a clean on-road record for the first time in six years with the installation of cameras on owned equipment. These proactive measures have not just cut down on-road deficiencies, but positively impacted the company’s insurance premiums.

“The communication between the coordinators at the ROC has been the biggest benefit by far,” Munna says. “By bringing everyone together, we’re able to make those last-minute, emergency decisions that save time and keep jobs going.”

As far as next steps, Latiolais says, “It’s now about fine-tuning processes and making sure we’re looking at the right things.”

One thing remains certain, though, is Barriere’s commitment to continuous improvement.

“At Barriere, we’re not about the ‘easy button,’” Quigley stated. “We’re about what it takes to be safe, successful and efficient.”