Know your limits

Don’t work on equipment unless you have the proper training

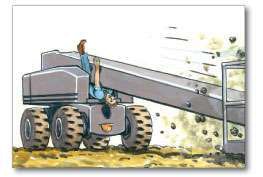

The bottom line: A post-accident investigation determined the company had not performed this type of repair work in the past, and the worker was not qualified to repair the lift. Furthermore, no lockout/tagout procedure had been implemented, allowing the lift’s boom to fall when hydraulic components were removed.

Follow the rules

Never attempt to repair a piece of equipment you are not trained to work on. ANSI specifications require a qualified person to repair the aerial lift according to manufacturer’s recommendations. Tony Groat, executive vice president of American Work Platform Training, notes that simply being a mechanic does not qualify you to work on all equipment. “Even being qualified on one model AWP does not qualify you to repair other types and models. They have different operating characteristics, safety devices and controls.”

Your employer will also conduct a job safety analysis to identify potential hazards. In this instance, an analysis would have determined a failure to either block the boom while in a raised position or lockout the hydraulic system could result in a boom collapse.

Step by step

If you are qualified to make adjustments or repairs, take the following precautions:

• Power stopped, with starting means inoperative

• All controls in the off position

• All operating systems secured from inadvertent motion by breaks, blocks, etc.

• Elevating assembly lowered to down position or secured by blocking or cribbing to prevent dropping

• Hydraulic oil pressure relieved from all hydraulic circuits before loosening or removing hydraulic components

• Safety props or latches installed where applicable

• Any further precaution recommended by the equipment manufacturer.

Only after a job safety analysis is completed and lockout/tagout procedures have been implemented, should you begin work on the lift.