Testing by traditional methods is necessary even when IC is used, but IC data cou

Even though IC is far from fully evolved, it is a huge leap forward in compaction technology. Because of this, agencies are including IC requirements in their projects more often and OEMs are expanding their IC offerings. IC offers value right now and no one’s waiting for IC to be perfected before applying the current state of technology.

Fundamentals

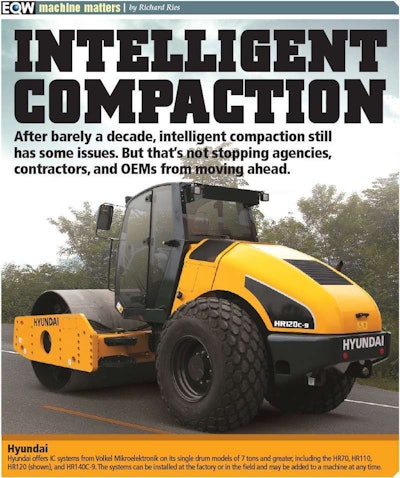

Steve DePriest, product specialist, Hyundai Construction Equipment Americas, says the fundamentals of IC are easy to understand. “Depending on the type of system, the information is displayed temporarily on a digital screen to provide guidance to the operator or, with advanced systems, displayed on the screen as well as stored for future evaluation and analysis.”

An accelerometer continuously measures the current state of compaction. As the degree of compaction rises the value disp

The Volkel Mikroelektronic IC systems offered by Hyundai can be installed at the factory or in the field. Current compaction equipment models can be upfitted with the system at any time.

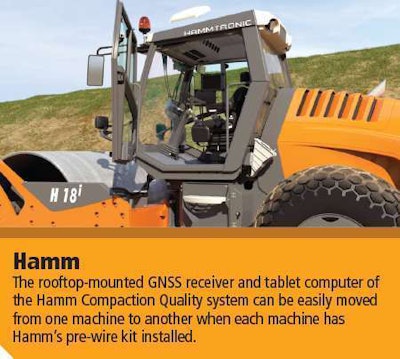

Hamm Compaction Quality (HCQ) pre-wire kits are available for all H i-series soil and HD+ and HD+ i-series asphalt rollers. Kits include accelerometers, temperature sensors, a mount for the GNSS receiver, and a mount for a tablet PC. This allows the GNSS receiver and tablet computer of the HCQ system to be moved among machines, even from soil to asphalt and pneumatic tire compactors. All relevant dimensional data, such as size and type of roller and offset of the receiver to the center of the drum, are shared with the system by the machine’s computer. This ensures consistently high accuracy as system components are moved from one machine to another.

The ruggedized tablet computer can show a split screen with two sets of data simultaneously. Stiffness and pass count are available with all rollers; asphalt rollers add mat temperature. HCQ allows communication between up to three rollers at once so operators can see others’ data in real time.

Location information requires a subscription to OmniSTAR. The service provides accuracy to within 10 centimeters, or about 4 inches. “We chose OmniSTAR because of its simplicity,” says Tim Kowalski, applications support manager for Hamm. “With differential GPS you get RTK-level accuracy without the use of base stations. OmniSTAR is available anywhere, anytime the machine is running, requires no set-up, and maintains its accuracy and signal strength as the equipment moves around the worksite.” The satellite signal is retained for up to 16 hours after shut-down to minimize signal acquisition time after breaks, at shift changes, at each day’s start, or whenever there’s a gap in operations.

Talk to me

It’s not enough to gather data. The data must also be shared. BCM 05, the current version of BOMAG Compaction Management, is one example of what’s available. The BCM 05 system has a touchscreen tablet PC, a lockable holder for the tablet, a USB memory stick and the BCM 05 software.

BCM 05 reports conditions to the roller operator using a color-coded display and numbers. Comparisons to previous passes and to target values are indicated. Problem areas — such as those that cannot be compacted or are at risk of being over-compacted — are shown. Date and time are documented. All information can be transferred to a desktop or laptop PC using the memory stick for project management, statistical analyses, archiving, printing, and program calibration.

With the addition of BCM 05 positioning software and a GPS receiver, location information can be added to the data. BCM 05 positioning can interface with a conventional differential GPS (DGPS) system and works with or without a reference station. BOMAG says the system is compatible with any currently available DGPS system. With a satellite-assisted reference service positional accuracy is at least 20 centimeters (less than 8 inches). “BOMAG has been working with IC since the 1980s,” says Bert Erdmann, director of engineering/product management heavy compaction, for BOMAG Americas. “The BCM 05 serves as our latest reporting vehicle for machine location, temperature stiffness and other values captured by our advanced IC systems, Asphalt Manager and Variomatic.”

Communication must be both ways, says Kowalski. “Someone has to manage the system, setting indicator colors, giving names to projects and parcels, and doing all the background work necessary for successful implementation of IC. Even though it’s straightforward and comparatively easy work, it’s a big responsibility. Some customers think you simply add an IC setup to an existing roller and you’re done. There’s much more to it than that.”

From large to small to not at all

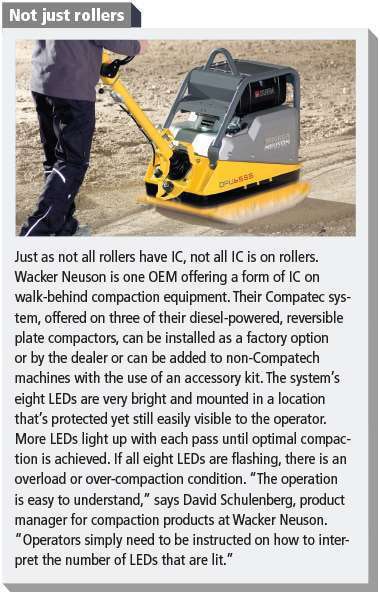

Pullen says “There are many definitions of intelligent compaction. All Case compactors have a degree of intelligent compacti

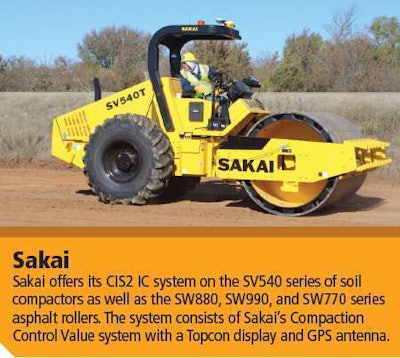

Josh Steele of Sakai says, “Because not all systems are created equal, customers need to perform due diligence. There are more aspects to consider than just meeting the reporting specs. IC complements jobsite analysis leading to higher efficiency of everything you do. When integrated with other smart-machine applications, IC data can show areas where more training is required, where fewer machines are needed than expected, or where production should speed up or slow down to meet quality measures.”

Chicago Pneumatic is one of several OEMs not offering IC on any of its compaction equipment. “There’s not a lot of demand for it in the markets we serve,” says Paul McClendon, south central sales manager for CP. “We’re big in the rental market and oilfield services whereas IC is popular with heavy and highway contractors doing large projects.” He says IC appears mostly at the 5- to 6-metric ton rating and up on machines with rollers of 66 and 84 inches. Chicago Pneumatic’s largest model is the SR130D with an operating weight of 4.81 metric tons and a drum width of 53.9 inches.

A different drummer

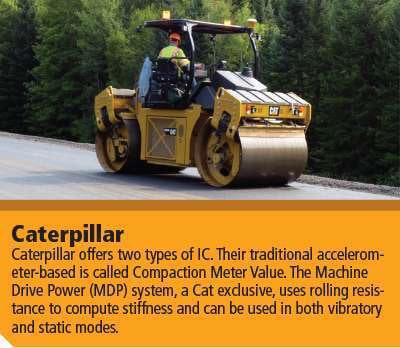

Caterpillar offers temperature and compaction measurement technology for asphalt and soil applications, including traditional accelerometer-based IC, which they call Compaction Meter Value (CMV). As with other such systems, CMV measures ground response to the vibratory impact of the roller. Accelerometer-based systems, including CMV, find subsurface anomalies, such as boulders and tree trunks, up to 2 meters deep. “But accelerometer-based systems work best in granular soils,” says Bryan Downing, global sales consultant for Caterpillar Paving Products. Cohesive soils distort the response to compaction, yielding highly variable measurements.

So Caterpillar developed Machine Drive Power (MDP), which relies not on an accelerometer but on rolling resistance. Rolling resistance decreases as materials go from loose to stiff and MDP uses this principle to provide compaction data.

MDP can be used on all soil types (granular, cohesive, fines) because the damping effect of troublesome soils has a signific

While accelerometer-based systems are “blind” with the vibration off, MDP works with the vibratory system on or off. This system functions in production mode where the amplitudes are high and the work of compaction is greatest, but also in a static “proofing” mode where the vibratory system is deactivated. This allows material measurement with minimal risk of de-compaction.

Another step closer

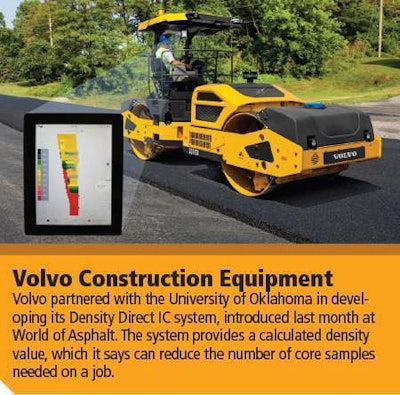

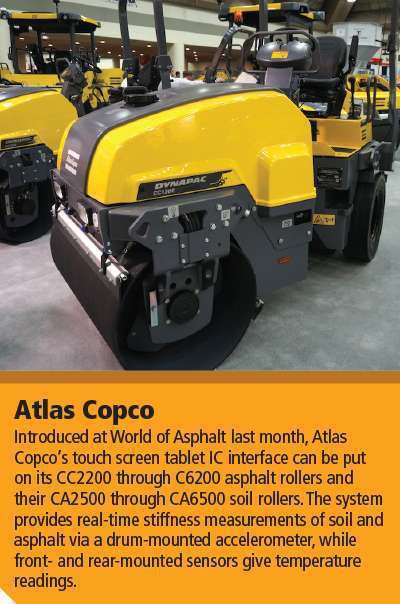

At last month’s World of Asphalt, Volvo Construction Equipment unveiled Volvo Intelligent Compaction with Density Direct, an intelligent compaction system that calculates density. This is the first time IC has been able to provide density calculations and is a major development in bringing IC to maturity. The density algorithm and its use on the compaction of flexible pavement is patented by the University of Oklahoma. Volvo Construction Equipment partnered with the university on its research and has exclusive rights to commercialize the technology.

The significant difference between Volvo IC with Density Direct and all other IC systems is that the Volvo system provides a calculated density value, where most other systems provide intelligent compaction measurement values (ICMV) based on calculated mate

“Density Direct can reduce the need for additional core sampling for quality control and improves productivity and quality,” says Mark Eckert, compaction product manager, Volvo. “Operators now receive real-time density calculations covering 100 percent of the compacted mat.” Eckert says that Density Direct is a better solution than traditional nuclear gauge testing, which is more time consuming and provides only spot-check results.

The target density given in project specifications is entered using a calibration touch screen; that specification is typically between 92 percent and 97 percent. Density Direct runs that target percentage against a range of data including material thickness, material temperature, material mix, compactor weight, amplitude, and frequency. When calibrated against cores taken from a test strip, Density Direct is accurate to within 1.5 percent of lab-tested core samples, providing real-time density values over the complete pavement surface.

Volvo will offer both Volvo Intelligent Compaction (Volvo IC) and Volvo IC with Density Direct in North America. The system will be available in Fall 2015. Initially, the systems will be a factory-installed option on new asphalt compactors models DD110B, DD120B and DD140B. There are plans to offer Density Direct as an aftermarket option for Volvo asphalt compactors for sale exclusively through Volvo dealers at a later date.