A Washington company says it has developed a way to capture carbon from natural gas and use it to make asphalt to build roads.

Modern Hydrogen uses a process called methane pyrolysis that produces clean hydrogen out of methane and captures the carbon from that gas before it reaches the atmosphere. Methane, which is four parts hydrogen and one part carbon, is the largest component of natural gas.

The captured carbon is a solid carbon byproduct called “carbon black” that can be used as binder in hot-mix asphalt, cold patch and asphalt sealers, the company says.

The carbon-captured asphalt has already been used for sealing an asphalt parking lot in Portland, Oregon, and for paving a driveway with hot-mix asphalt in Seattle (see the video at the end of this story). The product has also been used in private parking lots and driveways in California, New Mexico, Florida and in Alberta, Canada, the company says.

Road Recyclers, an Austin, Texas-based designer of asphalt binders for the road recycling industry, has signed on to be “the first to incorporate carbon stripped from natural gas in public roads,” according to Modern Hydrogen. Road Recyclers has been testing Modern Hydrogen products and says it is now ready to begin field trials with partner municipal and state transportation agencies.

How It Works

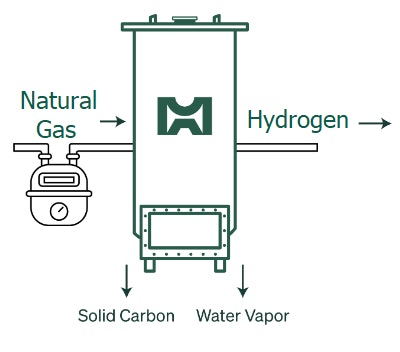

Modern Hydrogen's technology separates hydrogen and carbon from natural gas at the meter. The hydrogen is used for clean fuel, while the carbon is captured as a solid for use in asphalt and other materials.Modern Hydrogen

Modern Hydrogen's technology separates hydrogen and carbon from natural gas at the meter. The hydrogen is used for clean fuel, while the carbon is captured as a solid for use in asphalt and other materials.Modern Hydrogen

Modern Hydrogen developed a system to remove carbon from natural gas at the meter for commercial and industrial operations, before it is burned and produces carbon-dioxide that enters the air. It uses “a uniquely clean combustion process” with an onsite hydrogen generator to separate carbon and hydrogen, it says.

After removing the carbon, clean hydrogen is left to be burned for fuel. The company says it can then use that hydrogen for low-carbon heat, steam and power generation and fleet fueling. It says it uses no new pipes, no new electrical connections or onsite storage.

The process creates solid carbon and water vapor as byproducts. The solid carbon can then be recycled into asphalt. The material can also be used in concrete and rubber.

Modern Hydrogen says the low-carbon asphalt meets existing requirements at a low cost and is even more durable.

“The solid carbon we pull out from the gas is directly weighed, so every ton of solid carbon we put into products and building materials are verifiable emissions captured, avoided and utilized,” says Modern Hydrogen co-founder Max Mankin.

Check out this video below of a driveway in Seattle being paved with hot-mix asphalt made with Modern Hydrogen's captured carbon: