The following equipment was chosen by Equipment World editors as the top roadbuilding products of the year.

PAVERS

Sliding seat and console

Reduce need for rollers

Dynapac says it can achieve 94 percent pre-compaction with the new TH E Series tamper, high-compaction, electric screeds for its highway-class pavers. A hydraulic pressure plate on the back of the screeds helps achieve the higher compaction, which can lead to up to a 50 percent reduction in roller compaction. Operators can adjust the pressure plate’s vibration via the screed remote-control panel or by the main operator station. The screeds come in two models, the V5100 TH E and V6000 TH E, with working widths up to 29.5 feet.

Heavier screed, greater compaction

Electrically heated screed

Mauldin made its electrically heated Freedom Screed standard on the new 760 gravity-fed paver. A 12-kilowatt mounted generator delivers heat through six heating elements. The screed’s temperature can be controlled from a 5-inch screen on the dash panel. The Freedom Screed with Automatic Extension delivers paving widths of 8 to 13 feet. The 760 comes standard with steel tracks. Poly pads are optional. It can be equipped as a wheeled paver with rubber tires. Hopper capacity is 6 tons. Max paving depth is 6 inches.

Fuel-efficient engines

Volvo Construction Equipment designed its new P5110B tracked and P5170B wheeled pavers for heavy commercial and light highway work. The 20-ton pavers run on Volvo’s D6 173-horsepower engine, also used in its L60H to L90H wheel loaders. The tracked model uses on average 3.7 gallons per hour, and the wheeled paver, 3.3 gallons per hour. The engine is also designed to reduce vibrations and produce a low noise level of 79 decibels. The UltiMat160 screed delivers paving widths of 8 to 18 feet with extensions. The hopper has a 12-ton capacity.

COMPACTORS

Make fewer passes

Case Construction Equipment’s PT240D pneumatic tire roller is designed to require fewer passes and improve penetration and compaction density. The roller has four tires in front and four in the back with 2-inch tire overlap that gently kneads hot-mix asphalt as it rolls across it. The company says that leads to greater asphalt density and reduces the chance for voids. It is built for sub-base and asphalt compaction on large road and highway projects. Compaction width is 78.2 inches. Operating weight is 21,380 pounds and 52,910 pounds at full ballast.

Change timing belt in 2 hours

Simpler ballasting system

Dual-drum oscillation

With the SW994ND, Sakai has introduced its fourth compactor with dual-drum oscillation. The 84-inch-wide double-drum roller can handle dense-grade hot-mix as well as stone matrix asphalt mixes for highways. Sakai’s oscillating models are gear-driven, so no belts need to be replaced. The dual-drum oscillation enables the compactor to more efficiently achieve required density and surface textures, the company says. Both drums can also be switched to vibration. The SW994ND has an operating weight of 31,570 pounds.

High-frequency vibration

Volvo Construction Equipment‘s DD128C double-drum compactor features class-leading vibratory frequency for increased productivity. The 79-inch-wide DD128C has an amplitude range of 0.003 – 0.03 inches for compacting an ultra-thin lift up to a 4-inch lift. Volvo CE says the compactor maintains proper smoothness with the Impact Spacing Meter, which provides a visual reference of speed control. The DD128C can also automatically limit machine speed for impact spacing. An automatic drum-wetting system adjusts water flow to drum speed.

MILLING

Change cutting teeth quicker

BOMAG’s BM 2200/60 cold planer features the company’s BMS 15 milling tooth holder system, designed to increase productivity while also extending service life up to 30 percent. The system has a quick-change design that can reduce replacement time of a full set of teeth over conventional systems. The cold planer has an 86.3-inch cutting width and can cut down to 12.6 inches. Conveyor roller placement improves material flow for more efficient removal of millings from the cutting chamber. A new integrated dust extraction system helps to improve the operator environment.

Added safety for milling operations

Roadtec’s half-lane RX-505e/ex cold planer comes with some new safety features. Rear object detection automatically stops the machine from moving in reverse when it detects a person or object. Mill Maintenance Mode allows the compressor to run to power a drill for removing cutting teeth, while shutting down the drum drive. The RX-505 has cutting widths of 79 or 86 inches. It cuts as deep as 13 inches and runs on a 610-horsepower engine. The height of the operator seats can be adjusted, and the seats can be stowed for additional standing room.

Reduce operator workload

Wirtgen’s flagship cold planer models, the W 220 Fi and W 250 Fi, come standard with the company’s Mill Assist machine control. The large milling machines can cut to depths of 14 inches and widths of 86 inches. The W 220 runs on an 801-horsepower engine, while the W 250 has a 1,010-horsepower engine. Mill Assist automatically adjusts the speed of the engine, drum, traction drive, water system and the machine’s advance rate. The company says this reduces the operator’s workload while improving machine performance and fuel efficiency.

ADDITIONAL ROAD EQUIPMENT

Protecting the newly paved surface

The Air Bi-Fold Ramp system from Felling Trailers is designed to protect the surfaces beneath the trailer, such as newly paved roads. The new system is featured on the company’s 25-ton FT-50-3 LP triaxle, low-profile flatbed tag trailer and is designed for low-clearance machinery, such as pavers. The flip ramps lock out fully when extending to prevent scraping the ground. The controlled-flow air ramp also provides soft contact with the ground. The ramps are 45 inches wide and bifold to 11 feet. Their length and 9.5-degree load angle provide a gradual incline.

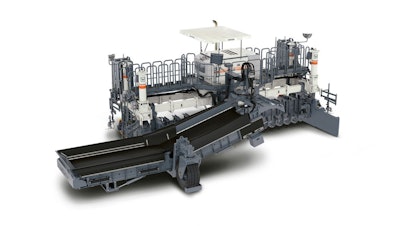

Reinvented shuttle buggy

Roadtec reinvented its SB-3000 Shuttle Buggy for 2020. The material transfer vehicle has new operator stations that give the main operator improved sight lines and protects the ground operator inside the structure of the machine. Service points are all at ground level for better access. The MTV has four steering modes: crab, coordinated, front only and rear only. Other features include a tight turning radius, backup camera, backlit control pods, fixed fume extraction, lighted egress bridge and ladder, and truck signal lights.

Grader for road maintenance

Sany built its new SMG200C-8 motor grader for maintaining and repairing roads. The cab features a rearview camera, a steering wheel for traveling and joystick controls for grading. A 252-horsepower Cummins engine drives the machine through an eight-speed transmission and an operator-controlled locking differential and electronically locking rear differential. The moldboard measures 14 feet wide, and the motor grader weighs 45,107 pounds. The cab is air conditioned and heated and offers an air ride seat.

Moving ahead of the paver

NEW TECH

Monitor asphalt temperature in real time

For contractors who want to monitor asphalt temperatures in real time, Caterpillar has a new thermal imaging system. The Thermal Mapping system includes an infrared camera and Global Navigation Satellite System that can be retrofitted to Cat’s pavers for achieving optimal paving quality. The camera is mounted to a fixed mast and has no moving parts. Thermal imaging can identify variations in temperatures, allowing contractors to manage the material-delivery process and make adjustments to achieve uniform temperatures.

Get concrete mix test results on phone

Hilti’s new Concrete Sensors enable contractors to use a mobile app for real-time monitoring of concrete as it cures and dries, as well as receive tests of the mix design from the company’s in-house lab. Sensors are attached to rebar with zip ties within 6 inches of the surface. Strength, temperature and relative-humidity data are sent to your phone in real time. Mix design results from the in-house lab are also sent to your phone. The sensors have a battery life of two-plus years. The company will also provide onsite training and support services.

Wirelessly monitor concrete curing

Maturix Smart Concrete Sensors wirelessly monitor the concrete hardening process, eliminating the need for manual data collection. The sensors transmit concrete temperatures at chosen depths in real-time to internet-connected devices. The system then automatically estimates the concrete’s maturity and strength. The concrete sensors’ batteries can last for 10 years. The sensors receive temperature data from thermocouple wires attached to rebar before concrete is poured. The wire is plugged into a reusable sensor to transmit data every 10 minutes.

Monitor paving data in real time

Vögele’s WITOS Paving Docu allows paving data and delivery notes to be recorded and automates the process of sending out jobsite reports. The software application for road construction is designed to bridge the gap between the company’s RoadScan paving temperature management system and WITOS Paving Plus telematics. WITOS Paving Docu records paving and paver data such as working width and paving speed. Delivery notes can be scanned in to continuously calculate paved areas, material quantities and densities.