Chris Meyer was 18 and working in a retail shop when his grandfather walked in the store one day.

James A. Rogers had started his excavation firm in 1962 and built it up over the years through determination and hard work. He asked Chris if he wanted a raise.

“I’m making $7.75 an hour – of course, I want a raise,” Chris replied.

Equipment World

Equipment World

In 2015, Chris bought the company from his grandfather. “I was his retirement plan,” he says.

Since purchasing the company, Chris, now 34, has more than doubled the annual revenues, modernized the internal processes and added new technology, among other improvements. He’s also come up with an innovative, yet surprisingly simple way to train young workers.

That and more is why he is one of Equipment World’s 2021 Contractor of the Year Award finalists.

Taking a gamble

“He built a company with grit, blood, sweat and tears,” says Chris of his grandfather. “He didn't have much training other than on the job, a life of hard knocks training.”

Chris relied on his grandfather’s wisdom and knowledge of the construction industry in Arkansas.

“I pick his brain about every little thing I can possibly do to make sure that I'm not going to make a mistake that he's already made,” Chris says. “He's forgotten more than I know. So he is definitely a huge asset still to the company.”

His grandfather prepared him well for everything from bidding jobs to seeing them through to completion. But Chris soon realized he needed help with the inner workings of the business.

“He ran the company by his gut and what was in the checkbook,” Chris says. “I couldn't do it.”

In 2018, Chris decided to reinvest $250,000 in the company. “Everybody thought I was crazy,” he says.

At the time, the company had plenty of work and was bringing in around $4 million a year in revenue. But he saw that though the company was profitable, it wasn’t growing.

So Chris plowed money into updating the company’s bidding software, its accounting, and its processes and procedures, including safety and human resources. The company had no employee benefits, so he set up company-paid vacation, health insurance of which the company pays 80%, and a 401(k) plan.

He hired an engineer for project design and estimating and hired a project coordinator. He praises project coordinator Pat Dry for helping to streamline operations. “Before Pat, I was trying to wear all the hats. And it was increasingly stressful for every aspect of my life,” he says. “Bringing her in has literally changed the whole atmosphere. It's not as stressful. … It has streamlined everything for our superintendents.”

It also created more of a team focus.

“The teamwork that we all have, we work together,” Dry says. “It's more of a family. And they seem to all have the same end goals, which is: make it all work.”

The 'sandbox' talks

Chris Meyer shows the "sandbox" where he gathers workers to go over the jobsite so everyone knows what they are supposed to do.Equipment World

Chris Meyer shows the "sandbox" where he gathers workers to go over the jobsite so everyone knows what they are supposed to do.Equipment World

“I mock up the jobs in the sandbox with kinetic sand and die-cast equipment,” he says. “You would actually be amazed how much that does help. Because it gives them a bird's eye view of what we're doing.” (For more on how Chris uses the sandbox to help young workers, check out this video.)

Chris also makes a point to retain his workers and show the younger ones their potential career path. He has four workers under age 25 he has already let know he sees them as his next generation of superintendents.

“It's not necessarily dangling a carrot in front of him, because that's not the point,” he says. “But this is where I plan for you to be in the next five to 10 years.”

“If we don't start treating them as superintendents, training them as superintendents right now,” he adds, “we won't have them when we need them.”

Growing with GPS

All of James A. Rogers Excavating's jobsites have a dozer with 3D machine control.Equipment World

All of James A. Rogers Excavating's jobsites have a dozer with 3D machine control.Equipment World

“It 100% effectively increases our production rate,” Chris says.

It took about two years to recoup the costs of the equipment. There are times when it runs into interference, mostly due to trees. He purchased additional satellite access, which has boosted coverage.

But the 3D system is only as good as the information it receives. He had to set some procedures for superintendents, and each one keeps those procedures in his truck. “So we came up with examples and procedures of what the guys needed to do, what the superintendents needed to do, so that we wouldn't make little mistakes here and there,” he explains.

Taking it to the next level

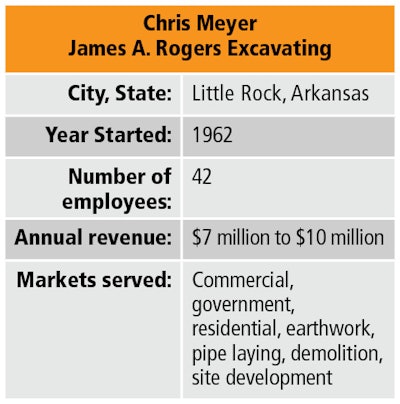

Since buying the company, Chris’ changes have helped double the firm’s annual revenues to about $9 million. It performs earthwork, pipe laying, demolition and site development for commercial and government projects, and some small residential jobs.

Today, James A. Rogers Excavating has 42 employees, including Chris’ family members. His mother, Sheri, runs the office as she has done for 28 years while working for her father. Chris also hired his father, Ken, for accounts management. His brother, Bradley, is a superintendent. And his grandfather still comes by to pitch in.

The James A. Rogers Excavating team includes, from left, Pat Dry, project coordinator; Heidi Valdez Roeglin, office system coordinator; Dee Osieczko, project estimator and engineer; Sheri Meyer, office manager; Ken Meyer, senior accounts manager; Chris Meyer, president; and company founder James A. Rogers.Equipment World

The James A. Rogers Excavating team includes, from left, Pat Dry, project coordinator; Heidi Valdez Roeglin, office system coordinator; Dee Osieczko, project estimator and engineer; Sheri Meyer, office manager; Ken Meyer, senior accounts manager; Chris Meyer, president; and company founder James A. Rogers.Equipment World

“That job was probably one of the most challenging jobs we’ve ever done,” he says. It involved removing 30,000 yards of mucky sediment that he called “pure slop.” On another section of the project, they had to call in a contractor from Georgia for blasting 10,000 yards of hard rock.

“It was $3.7 million job, and it went almost to $6 million after all the change orders and unforeseen conditions that took place in that project,” he says.

Other projects include levee repairs for the U.S. Army Corps of Engineers, site work on a 23-acre expansion of a condo complex, and installing retaining walls, storm drainage and water and sewer on an 11-acre senior living facility project. They also perform grading and build the base for road and highway projects.

Bradley Meyer, superintendent, James A. Rogers ExcavatingEquipment World

Bradley Meyer, superintendent, James A. Rogers ExcavatingEquipment World

Following a vision

Although he’s changed the company’s internal framework, Chris has maintained the same customer service philosophy he learned from his grandfather. And his clients and those he does business with appreciate it.

“If I need him, he's there,” says Shane Scott of F&F Construction. “And I wouldn't use anybody else. Because when I hire them to do a job, I don't have to babysit it. If we have an issue with something, we resolve it right away.”

“Chris Meyer is driven by getting the job done correct the first time,” says Ross Herlocker, premier account manager at Riggs Cat. “The employees are committed to making that happen.”

Rogers Excavating is also heavily involved in the community. It partners with Special Olympics; the Be Pro Be Proud workforce development program with the Arkansas State Chamber of Commerce; One More for Brent, which raises money for lifetime hunting and fishing licenses for children ages 6 to 18; and Valor and Honor Outdoors, which takes veterans and first responders on outdoor adventures.

Chris says his vision for the company is to rise into the $10 million to $12.5 million range in annual revenue. Beyond that, he says, would likely involve expanding outside of Arkansas, which he doesn’t want to do. He does foresee expansion into northwest Arkansas, where rapid growth has been occurring. The pandemic has delayed those plans, but he expects to add an office there in three to five years.

Above all, he wants to continue to build on the company’s reputation for quality work and reliability.

“I want to be known for doing a good job, being respectful, taking care of issues if we create them,” he says. “I want to be a part of doing that and growing that.”