But installing and maintaining bulk fuel tanks requires you to follow a host of federal, state and local regulations. And once you start dispensing your own fuel, you are responsible for keeping it free from water and contamination.

While many construction firms cycle through their fuel fast enough to reduce the effects of contamination, water and microbial contamination tend to increase in fuel stored over longer periods of time (for example generator fuel). Proper storage-tank design and maintenance is your best line of defense against all these ailments.

Dos and don’ts of tank design

For construction fleets, above ground storage tanks (ASTs) are almost always the best choice. Purdue University conducted a study of ASTs and noted their primary advantages are that they can be easily inspected and painted, making leaks less likely, and they can be safely relocated to a different part of the property as circumstances dictate.

Drawbacks to ASTs noted in the Purdue study were that vehicles can back into them, vandals can deface or damage them and trespassers can siphon off fuel. Additionally, ASTs are vulnerable to high winds, flooding, theft and vandalism.

There is also the potential for soil and groundwater pollution from leaks. Even one drop per second can release of 400 gallons of fuel into the groundwater over the period of one year if there is no secondary containment.

Letter of the law

As mentioned, there are a number of federal, state and local laws and regulations you must adhere to when you install an AST on your property. Note, however that state and or local laws may be more prohibitive and should be researched before arbitrarily locating a tank on a jobsite. “Know your laws,” cautions Brian Young, equipment division director with Portland Oregon-based Baker Rock Resources. “We found they were very specific to zoning.”

As a minimum, Purdue University suggests the following guidelines:

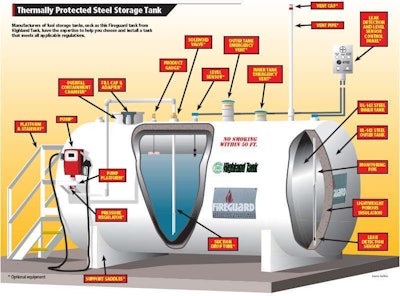

• A tank intended for outdoor use should have an Underwriters Listed (UL) outdoor-use designation.

• Indoor basement tanks are not intended for outdoor use.

• Tanks designed for flammable liquids such as gasoline should be fire-guarded or vaulted to prevent fuel ignition for two hours during a fire.

• Diesel fuel tanks do not have to carry a two-hour fire rating if the flash point is greater than 100-degrees Fahrenheit.

• A “secondary containment” area must have the capacity to hold the contents of the primary tank, should it fail (recommended 125 percent).

• Double-walled tanks satisfy secondary containment requirements, as do dikes or “bathtubs” in which the primary tank is situated.

• Double-walled tanks are preferable because rainwater is not a problem; conversely, removing accumulated rainwater from dikes can be a hassle.

• Every fill-up poses a spill risk, so limit fill-ups to once a month by selecting a tank that will hold a month’s supply of fuel. In selecting a tank size, calculate its usable volume, giving consideration to the fact that the pump intake is situated several inches above the bottom of the tank, which reduces the volume of usable fuel. Also, tanks should be filled to no more than 95 percent capacity to allow for expansion.

Another good set of guidelines comes from the National Fire Protection Association (NFPA). They recommend:

• Any AST be located on a high, well-drained site, a minimum of 40 feet (including fueling apron) from any buildings, water tributary or combustible materials.

• The storage area shall be free of weeds and other combustible material.

• Open flames and smoking shall not be permitted in the area.

• The tanks should be installed in an east-west orientation to reduce the amount of solar radiation the tank receives.

• The AST should be marked with the name of the fuel contents and a sign with “FLAMMABLE–KEEP FIRE AND FLAME AWAY.” The words should be at least six inches in height and be in a bright red color.

• “NO SMOKING” signs should also be conspicuously exhibited from various angles of approach.

• Class B type fire extinguishers should be mounted in easy to access locations.

• Do not place tanks where ignition sources such as welding and cutting torches are likely to be used.

• Tank saddles (either concrete or steel) are required by law unless tanks in contact with the ground are protected against corrosion.

• A roof structure is recommended to reduce evaporation and condensation effects and to keep water from collecting in the catch basin. It also provides shelter, to some extent, from the direct rays of the sun to minimize over-heating.

While it is possible to fabricate your own tanks, you still have to buy pumping and dispensing equipment, and the tank must meet all applicable codes and regulations. A less time-consuming strategy may be to purchase a complete tank from a reputable source such as Highland Tank. Another possibility is to check with your fuel supplier. “Some suppliers will provide a fuel tank at no charge if you commit to buying a predetermined amount of their product,” says Young

Contamination and monitoring

“Our fuel tanks sit in our shop yard and many of our asphalt plants,” says Adam Ridell, equipment manager for Superior Bowen, a Kansas City-based paving company. When the lids are opened to be filled by our vendor in these dusty environments the tanks act as vacuums and suck all types of debris in. It is important to understand and manage the quality of the fuel that is being put in your tanks and to take preventive measures with year-round or winter treatments to prevent corrosion, gelling and plugging,” he says.

And while you are responsible for the quality of the fuel once it’s in your tank, you can work with your fuel supplier to keep deliveries clean. “Have your fuel distributor use 4-micron filters on their distribution trucks,” says Ben Tucker, equipment manager for Barriere Construction out of New Orleans. “We use the same on all our fuel tanks. We have cut our fuel related problems by 75 percent with this implementation.”

Test for water

Periodic tank content samples can be taken with a Cim-Tek Filtration Tank Sampler Kit or similar sample extraction methods. Tank samples can also be sent off to a lab for analysis. Most labs that perform oil analyses can analyze fuel samples for water content.

A quick and simple method to assess presence of separated water in the fuel tank is to use Kolor Kut or Gasoila Water Finding Paste on a dipstick. After smearing the paste on the dipstick and vertically inserting it to the bottom of the tank, the extracted dipstick will show the presence of water from discoloration on the stick.

When separated water begins show, it is best removed before it becomes too severe. To clean tanks an electric pump with a stiff PVC pipe can be used to suck the water out of the bottom. Use a clear hose to see when the water is drained off. As soon as the water is drained out, shut the pump off.

If your company has a computerized maintenance management system, you should put fuel tank testing and inspection into the system as a regular PM. This will help toward meeting EPAs Spill Prevention, Control and Countermeasure Plan (SPCC) Program and the Federal regulation 40 CFR 112 requirements. The PM inspection will also provide a record of the examination, a requirement under 40 CFR 112.

Training and risk management

Proper management of the risks associated with aboveground storage tanks is essential. Everyone who works on or around the equipment or the fuel storage locations should be trained to identify and eliminate risks. They should also know how to conduct routine inspections of fuel storage containers, dispense fuel and operate pump shutoffs properly.

Additional training should teach employees how to contain spills, conduct cleanup procedures, and how to safely operate the equipment. Involve your employees in scheduled reviews of your fuel operation and in identifying steps you can take to minimize spills.

Another way to keep tabs on your fuel storage tanks is to use a cellular GPS system, says Tucker, “We use cellular GPS monitoring on remote tanks to monitor level and time that fuel is dispensed. It also helps with filter changes on tanks and when jobs are fueling.”