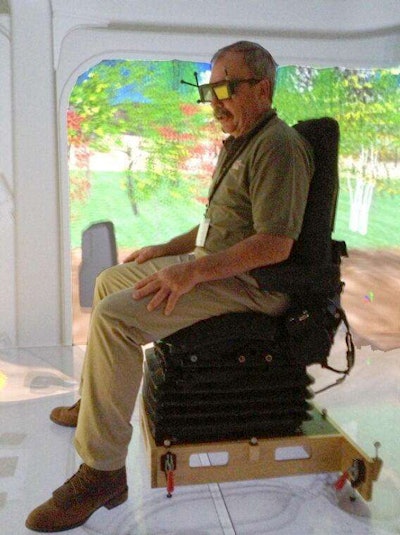

Phil Newberry sits in the Cat Immersive Visualization Center.

Phil Newberry sits in the Cat Immersive Visualization Center.If you’ve ever wondered just how much Caterpillar values customer feedback during the development of new equipment, just wait until you hear about the company’s virtual reality rig.

At the Caterpillar Technical Center in Mossville, Illinois, the equipment manufacturer invites groups of customers to step inside what it calls the Immersive Visualization Center (IVC).

The IVC is basically an equipment simulator that uses virtual reality to give customers a 1-to-1 ratio view of what the cab of a piece of equipment would be like. Recently, customers evaluated motor grader cab concepts in the IVC.

“The advantage of working in the virtual reality environment is that you can switch back and forth so customers can see the concepts side by side and instantly compare the key features,” Dan Gillen, Caterpillar’s product application specialist for Motor Graders, said in a prepared statement.

The IVC is composed of three walls, four screens, a floor and 12 high-definition 3D projectors. As one of the largest virtual reality systems on the continent, the Cat IVC creates an immersive 20-foot-wide and 10-foot-high-and-deep environment.

Randy Krieg of Wasilla, Alaska, is a former Caterpillar employee and an expert motor grader operator. Krieg was involved in the development of Cat’s M Series motor grader. He recently sat in the IVC and reminisced about early versions of the simulator used when he was with the company.

“The simulations we ran started with a chair, two cardboard boxes, some video game joysticks and a lot of wires running up to the screen,” he said. “We certainly have come a long way.”