Editor’s Note: This is Part 2 of our look at repurposing shipping containers for use as storage units and jobsite offices. To read Part 1, click here.

by Preston Ingalls

You should be aware of two distinct downsides to repurposing shipping containers: heat and humidity.

During the Vietnam conflict, shipping containers were repurposed by military units as storage for motor pool parts, aviation components and ammo – the forerunner to their use in construction.

In Vietnam, they were commonly known as “sweat boxes” because the heat from the tropical sun would produce dripping condensation inside where the average temperature was 15 degrees hotter than the exterior.

While most shipping containers in the United States won’t endure tropical conditions, the ceilings of many shipping containers will easily reach well over 100 degrees in the summer. The hot metal ceiling causes humidity in the air to begin to condense about 6 inches near the ceiling, which is referred to as the “sweat zone.” Droplets form on the ceiling and upper vertical band of the walls, producing what is commonly called “container rain” or “container sweat.”

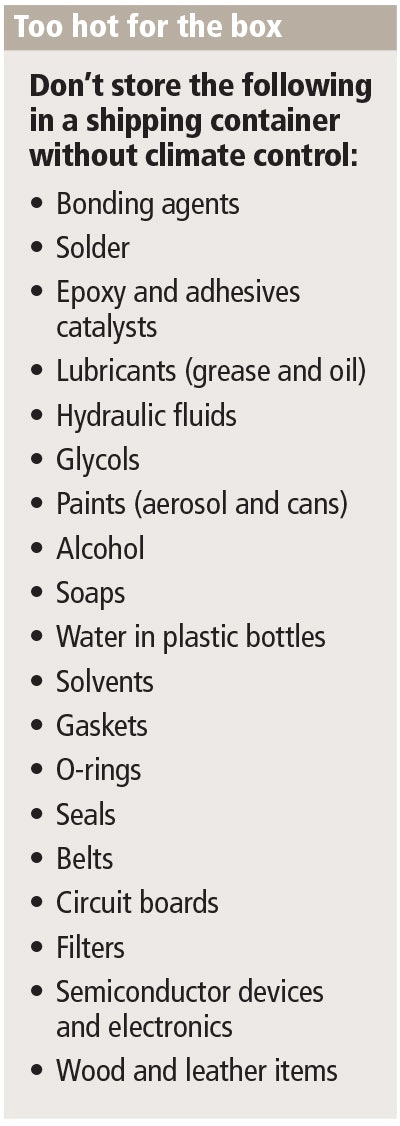

This level of heat and humidity is too much for a wide range of products and materials (see sidebar).

The humidity of the air changes only as a result of the change in temperature. When air cools, it becomes more humid even though the moisture content in the air remains the same. Warm moist air from the outside can also enter into a container through “container breathing.” This is where the container “exhales” as air expands during daytime heating and then “inhales” moist air through leaks and the seals when it cools at night. The temperature does not have to change for this to happen.

A good suggestion is to mount a $10 digital humidity and temperature monitor in the unit. Also, by putting several items in your storage container and examining what happens to them over time, you can determine if you need climate control.

For example, oil-filter media may dry and form cracks from heat or excessive cold, or they can become saturated with moisture from humidity. Cork, rubber or silicone seals can become brittle from high temperature and humidity ranges. Some estimate that long-term storage of filters in shipping containers will cut their normal five-year life expectancy in half.

Humidity can also cause solder joints on printed circuit boards to become brittle and crack. Chemicals and lubricants begin to separate, like paints and inks. The glue on furniture joints loses its bond and cracks. Moisture saturation from condensation or constant thermal expansion and contraction from heat has a wearing impact on many components.

Climate control comes in many forms

These problems have solutions. A common way to manage condensation is to control the air flow to keep the inside and outside of the container the same, or close to the same, temperature. Remember, temperature differential causes the dewpoint problem. Since the main keys to condensation control are ventilation and/or dehumidification, let’s look at eight solutions to the problem:

1. Storage container vents

Adding two vents at each end of the container provides ample airflow to keep contents dry. Vent types include fixed, louvered and rooftop turbines. While fixed vents are simple and effective, they can’t alter airflow. Louvered vents are more expensive, but they allow some flexibility over airflow. Both can be purchased online. Nonpowered rooftop turbine vents that can be mounted anywhere on the roof are the most popular, effective and expensive nonpowered ventilation option.

2. Air conditioning units

If you’re using the container for an office or workshop and have a power source, consider HVAC, such as a basic window air conditioner. Commercial through-wall HVAC systems from 1.5 to 5 tons are primarily used in harsher climates or for specific applications when climate control is of the utmost importance.

3. Exhaust fans

Exhaust fans are available in sizes of 10 to 36 inches. They come standard with fan guards and gravity shutters. Variable speed control is an option.

4. Dehumidifier

With electricity, dehumidification is an option. The addition of a discharge line makes for efficient elimination of condensed water and reduces maintenance and inspection.

5. Kitty litter

An open bag placed at each end of the container will absorb moisture. It’s inexpensive (a 40-pound bag costs around $25) but requires monthly monitoring and regular replacement based on humidity level.

6. Commercial desiccants

Products like Container Dri or DampRid can be placed inside the storage container to collect moisture. As with kitty litter, they require periodic monitoring and replacement.

7. Pole container desiccant

Pole desiccants come in different configurations, can absorb up to three times their weight in moisture and trap it as a thick gel that will not spill or drip. Pole variations use calcium-chloride salts to absorb moisture in a gel form that is permanently deposited into a built-in “tank” for evacuation. It requires replacement once the salts are exhausted.

8. Painting the container white

Painting the outside of the container white reduces the breathing of the container during a 24-hour heating/cooling cycle by reflecting the sun. As an extra precaution, consider using a zinc paint coating to slow rusting of the underlying steel. Quality zinc paint should contain at least 90 percent dry zinc powder.

Additional pointers to reduce the temperature and humidity

Ways to further reduce the temperature and humidity within the shipping container include:

• Place your shipping container in the shade, but not under trees.

• Build a roof over the container to reflect the light.

• Insulate the internal walls with traditional insulation or spray foam.

• Install cross ventilating windows.

• Install extractor fans to purge hot air.

• Arrange items for better air flow inside the container, such as stacking them off the floor on shelves or clean pallets, and avoid cramming the items tightly together.

• Mount a container on ConFoot legs for elevation that inhibits soil reactions and easier moving.

• Regularly monitor humidity with a moisture meter or, better yet, a temp gun (for ceiling temperature measurement).

• Set the container on gravel or 6-inch pressure-treated blocks for better air circulation.

• Park on high ground to avoid flooding and standing water.

• Keep the roof clear of leaves and moss since they trap moisture.

• Separate containers by 6 feet for better air flow.

• Avoid trees since windy locations allow storage containers to dry out.

• Add a roof-mounted, peaked tarp with a 2-foot overhang that avoids roof contact, to slow quick temperature changes.

• Keep air vents unblocked.

• Avoid storing anything inside with a high moisture content.

• Above all, use common sense and check on your container just like you would check on anything you own.

Remember the “doggy rule” when considering storing items in the storage container. If you wouldn’t put your dog in the container with food and water for a prolonged time, don’t store items that would react to the heat and humidity over a prolonged time.

![Solid Earth 1[4546]](https://img.equipmentworld.com/files/base/randallreilly/all/image/2018/03/eqw.Solid-Earth-14546.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)