The first year was rough, Corrigan admits. “I lived in the shop. Worked on bids at night and in the field all day. For the first four years all I did was work, sunup to sundown, lived it and breathed it.” he says. “It takes a toll on everything you do. You won’t see your friends anymore, unless you work with them. And your wife has to be pretty understanding.”

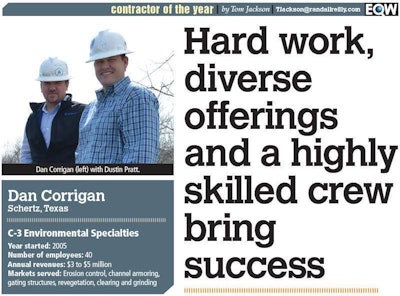

But thanks to strong relationships he had built in his previous work and the diversity of jobs he could handle, the business continued to grow and thrive. It also helped that his second in command, Dustin Pratt, who now runs the day-to-day operations, was with him from the start. They had met in Austin and worked for the same employer before Corrigan went out on his own.

Recessions and floods

When the recession hit, C-3 Environmental Specialties did what it took to survive. “We went from 40 employees to 15, took a bunch of equipment that was underutilized and sold it and consolidated the fleet to run more efficiently,” Pratt says. Things have gradually improved, though.

This year saw some real ups and downs. The first quarter was horrible, Corrigan says, because of the constant rain. But now that the rain has stopped, the company is back on track and has a huge backlog of work.

Jobs can range from the Rio Grande Valley to Waco and Houston. For 2015, Corrigan set a goal of increasing revenues by 20 percent, to be accomplished by bidding work further out in the state, looking at a different client base and capturing more market share in the San Antonio area.

Corrigan also tried his hand at running quarries, and even though he sold that business last year, it taught him a lot about efficiency and keeping his costs down. The quarry experience also taught him a valuable lesson. Corrigan learned not to fall in love with his yellow iron.

Equipment strategy

“The older equipment does not make you any money,” he says. “Keeping up with the repairs ate us alive. We finally learned that we have to reinvest everything. We trade up or we trade out. Dustin does a good job of covering our utilization, so if we’re not using something we don’t stay attached to it. We get rid of it. We’ll typically trade it or sell it for assets we know we can use.”

Most of his acquisitions today are new equipment, Corrigan says, or low-hour, well-maintained machines. But almost everything the company buys is from a dealer, whether it be trucks or equipment. “We’re firm believers in a good warranty,” he says.

The oil patch: opportunities and challenges

When unconventional drilling methods started unlocking new petroleum reserves in South Texas it presented C-3 Environmental Specialties and many other contraction companies a tantalizing choice – whether to take some of that site work or not.

“Oilfield work is a great thing, but the boom builds a false sense of security for some guys,” Corrigan says. “They go down there chasing the money and they get used to it. But most don’t save any money. It happens about every 10 years. It’s pretty easy to lose down there.”

The other problem is the upward pressure the oil boom put on wages. “For whatever reason, guys who work there think their base pay should be around $30 an hour and that isn’t doable for us,” Corrigan says. “How do you compete against that? I’m glad we didn’t chase a lot of it. We had the opportunity, but we were busy enough up here at the time.”

What Corrigan is not going to lose out on are the good deals he’s seeing on used equipment now that work in the oil field work is declining. “A lot of those guys didn’t own equipment. They would RPO-it (rental-purchase option), and now all the equipment yards are stacking them up,” Corrigan says.

Social media recruiting

When C-3 Environmental Specialties is hiring it will use everything from small community newspapers to word-of-mouth to its website. But both Corrigan and Pratt are firm believers in the power of social media combined with word of mouth when it comes to finding entry-level candidates.

Their formula is to get all the employees and all their friends and relatives to use their social media channels to tell everybody that they are hiring. That not only expands the outreach exponentially, it gets the message out to young people who are a known quantity and more likely to be good candidates than the average stranger walking in off the street.

Diversity and experience = success

Corrigan says his company’s key strength is its size and the ability it has to offer more services. “We are a one-stop shop. That’s how we got into tree grinding,” he says. “We would always have to wait for the grinding crew to get to our job, so we bought one.”

Owning a tub grinder was intimidating at first, Corrigan says. “We didn’t know much about it. We knew enough to get it done, but how productive we would be was a big question.”

Solution? Corrigan hunted down David Bogue, one of the most knowledgeable grinder operators in the area with 20 years of experience. “He had left the industry and was doing something else, but he still had a passion for it.” Corrigan says. To start, Corrigan convinced Bogue to run their grinder on weekends, but he eventually came on full time with the company. “It’s been a great relationship,” he says.

Customer testimonials

A big part of C-3’s success lies in its diversity and the experience of its crews. “We’ve been doing work with them almost since they started,” says James Kearns of DNT Construction. “They always show up on time, they are fast and they do good work. They’re one of the sure things that we have.”

After a coming storm looked like it might ruin a nearly finished site, Kearns called Corrigan at 3 pm. “The crews got there at 4 pm and worked well into the dark to secure the site,” Kearns says. “That kind of thing happens so often I don’t even notice it anymore.”

Lauren Alaniz at Haynes Geo, a company that sells geotextile fabrics and erosion control supplies, says she’s impressed at well trained the crews are and the level of cross training among C-3’s employees. “The estimators know how everything goes in the field and everybody is on the same level as far as professionalism and knowledge,” she says.

“When times were good, instead of buying boats or building huge offices he reinvested in his company. They’re one of the few large contractors we deal with who didn’t drop out during the recession,” Haynes says.

Advice for new contractors

“The best advice I can give them is get a good bank, and accountant,” says Corrigan. “But it’s a lot of work. Expect the first few years to be really tough.”

Relationships also matter. “Everything in any business is relationships, building and nurturing relationships,” Corrigan says. “I spend a lot of time with them. Today it has paid off.”