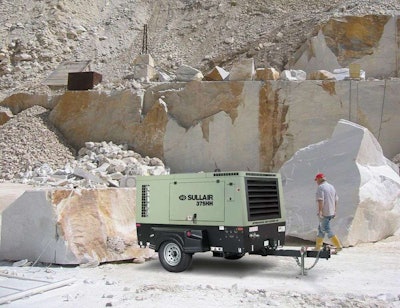

Rental compressors come in a variety of sizes,

Rental compressors come in a variety of sizes,including single tool air compressors, and compressors large enough to power rock drills in quarries.

1. What are you planning to do? Air compressors drive tools for a variety of jobs, including small scale tasks – such as nailing or chipping – up through cleaning, painting, blasting, demolition, drilling and boring.

The two most important statistics for any compressor is pressure (measured in pounds per square inch gauge, or psig) and volume (referenced in cubic feet per minute, or cfm). These numbers are either stamped on the tool, or stated in the owner’s manual, says Jenny Products.

Contractor-grade portable compressors generally run from around 15 cfm/100 psig up to about 2,232 cfm/175 psig. According to Kaeser Compressors, the most popular contractor rental size is 185 cfm, which will comfortably operate two 90-cfm pneumatic tools.

Most general construction applications, including the use of light pneumatic tools, require a compressor with operating pressures in the 100-psig range, says Doosan Portable Power.

2. What tools will you be using? Your rental dealer will be especially interested in giving you the right tool/compressor match. Applications such as blasting or painting often require compressors with operating pressures in the 150-psig range. Higher pressures are needed in applications such as drilling or boring, which need 250- to 350-psig compressors.

Many times, contractors will rent the tools along with the compressor, which simplifies tool/compressor matchups, says Kaeser.

3. How many tools do you need to drive at one time? A rental supplier wants to make sure it gives you enough power for your requirements. They will add up the air requirements for each of the tools that may be simultaneously attached to the air compressor and then add 30 to 35 percent to that number and choose a compressor to meet that need, says Atlas Copco.

4. Will you be working indoors? If you’re working indoors and can’t run an air hose inside, you’ll need to use a small, electrical unit, which provide flexibility but are not suited for all applications, says United Rentals. While diesel or gas units must be run outdoors, contractors typically place the unit outdoors and run the air line indoors to the work area.

5. Are you sandblasting? If so, you’ll need to answer questions about the required nozzle size, according to Chicago Pneumatic Construction Equipment.

6. Do you need a long air delivery hose? Sometimes air compressors will need to be positioned further from the work, requiring a longer hose, which in turn may limit the amount of air to the tool, says United Rentals. If a hose from the compressor to the tool is more than 300 feet, Chicago Pneumatic advises the compressor air pressure may need to be adjusted to provide adequate power.

7. what is the towing capacity of your transport vehicle? Some units can be easily transported in the bed of your truck, while others require a tow. If you choose to transport the compressor yourself, instead of having the rental dealer deliver it, make sure you know if your truck can legally tow the rented unit, Kaeser says. For example, a 185-cfm unit will run around 1,500 pounds without fuel.

Compressors come in single, double and triple axle versions, some of which are not towable down the highway. In the more common sizes, however, manufacturers use single axles for portability, according to Chicago Pneumatic.

8. How will you refuel the unit? Compressor fuel tanks are typically sized for eight to 10 hours of operation. Know how you’ll refuel the machine. And be sure you understand the service requirements of any unit you rent, adds Atlas Copco.

9. Is your personal protection up to snuff? Compressor users need to use ear and eye protection. Keep in mind that most tools you’ll be using are much louder than the compressor itself. EW