Concrete pavement is hand finished in advance of tining.

Concrete pavement is hand finished in advance of tining.MIT (Massachusetts Institute of Technology) researchers have discovered the beginnings of a new approach to producing concrete, which could lead to new ways to make concrete stronger and more sustainable with local materials as additives that will offset concrete’s greenhouse gas emissions, according to a release from the institute.

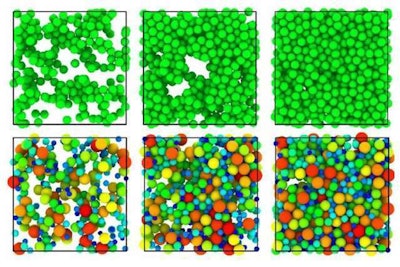

They also developed a computer model to simulate the behavior of individual atoms, which form molecular building blocks within a hardening material. The simulations showed that an interface within the molecular structure exhibited a “frictional” resistance under sliding deformation, so the team developed a cohesive-frictional force field, or model, that incorporates the atom-to-atom interactions within larger-scale particles, each containing thousands of atoms.

“The conditions of the world are changing,” Buyukozturk told MIT News. “There are increased environmental demands, including from earthquakes and floods, and stresses on infrastructure. We need to come up with materials that are sustainable, with much longer design life and better durability. That is a big challenge.”

“The material science of cement strength is still in its infancy regarding molecular-level descriptions and an ability to perform quantitative predictions,” Yip says. “The issue of frictional force, addressed in our work, pertains to the mechanical behavior of cement that varies over time. This rate sensitivity is an aspect of the scientific challenges at the mesoscale, which is the research frontier where microscale concepts and models developed in several physical science disciplines are linked to macroscale properties for technological applications.”

The team is now examining ways in which the cohesive and frictional forces of groups of atoms, or colloids in cement, are improved by mixing in additives, such as volcanic ash, refinery slag, and other materials. The computer model could help designers choose local additives based on the molecular interactions of the mixtures.

“We know relatively little of what happens when additives are used in concrete,” Palkovic says. “We would not expect volcanic ash from Saudi Arabia to give the same performance as volcanic ash from Hawaii. So we need this greater understanding of the material, that starts at the atomistic scale and accounts for the chemistry of the material. That can give us greater control and understanding of how we can use additives to create a better material.”

The results of the study have been published in the Journal of the Mechanics and Physics of Solids. The research was supported, in part, by the Kuwait Foundation for the Advancement of Sciences, as part of the MIT-Kuwait signature project on sustainability of Kuwait’s built environment.