For contractors wanting to ease into material crushing, attachments manufacturer Remu has launched a new product line of excavator crusher buckets.

The jaw crushers can process brick, rock, concrete and asphalt. They are made of Hardox steel and are powered by Rockzone rock crusher technology. The buckets first scoop the material and then crush it into small pieces that sift out the bottom of the buckets onto the ground. The operator does not have to leave the cab.

(To watch a Remu crusher bucket in action, check out the video at the end of this article.)

The buckets are ideal for demolition jobs, for processing the waste onsite and then reusing it or transporting it elsewhere. They're also a more affordable option to a crushing plant, Remu says.

Remu

Remu

The crusher buckets will be available in the U.S. toward the end of this year or early 2026, according to Remu.

The company says fine material does not interfere with the crushing operations. If unbreakable material enters the bucket, the rotor stops. The rotor direction can be reversed and the blockage material dumped.

“By integrating this equipment into operations, customers can reduce waste, lower costs and contribute to sustainable practices in the construction and demolition industries,” Remu says. The company adds that the buckets have low maintenance requirements.

To watch the Jaw 90 in action, check out Remu’s video below:

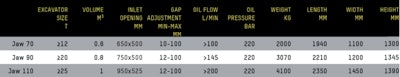

Quick Specs

Remu released the following spec chart for the Jaw crusher bucket lineup: