The new VT-70 High Output machine from ASV gives you high torque output over a wide range of engine rpms.

The new VT-70 High Output machine from ASV gives you high torque output over a wide range of engine rpms.ASV introduced a new Posi-Track loader, the VT-70 High Output, during a recent event held at its headquarters in Grand Rapids, Minnesota. High Output refers to the machine’s 207 foot-pounds of torque which helps tackle demanding applications and run more powerful attachments.

The big torque comes from a turbocharged Deutz 2.2-liter engine that cranks out 74.3 horsepower, which is 10 horsepower above what the company’s standard VT-70 machine offers. “It makes 74.3 horsepower at 2,600 rpm, but it has an exceptionally good torque curve, which means it also makes 74.3 horsepower clear down at 2,200 rpm,” says Buck Storlie, product line manager for ASV.

Direct drive pumps on the ASV VT-70 High Output optimize the hydraulic performance over belt driven designs putting out 3,300 psi of auxiliary pressure and 22.2 gpm of flow. An optional 27.4 gpm high flow system is also available.

When it comes time for service, ASV’s three-panel engine access doors and swing-out radiator give you easy ground-level reach to all the service points, filters, battery, and drain plugs. For access to daily grease points, all the zerks fittings are located at the ends of the pins.

Ergonomics

Controls for the ASV VT-70 High Output are located on the two joysticks (that is to say, no foot pedals.)

Ride control is available to dampen the load in the bucket, reducing spillage and keeping the operator more comfortable. An optional bucket positioning system also reduces spillage.

Lowered by three inches, the step-in point on the ASV VT-70 High Output makes it easier to get in and out of the machine and improves visibility to the blade or attachments.

Lowered by three inches, the step-in point on the ASV VT-70 High Output makes it easier to get in and out of the machine and improves visibility to the blade or attachments.ASV also lowered the step-in point on the new loader by almost three inches making entry and exit easier and giving you a better line of site to the bucket and the attachment points. A new foot-well design with an additional 3 inches of forward clearance makes room for big-booted operators.

The new machines also have new seat with a higher back for better lumbar support and suspended and air-ride options.

To see the ASV VT-70 High Output in action see our video below:

Undercarriage like no other

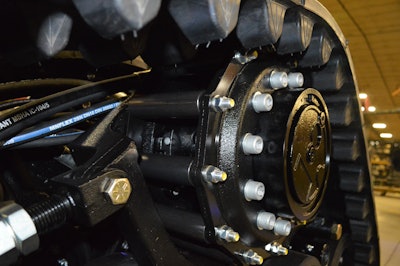

Rollers rather than gear teeth, drive the track lugs forward, reducing friction and improving the undercarriage life.

Rollers rather than gear teeth, drive the track lugs forward, reducing friction and improving the undercarriage life.ASV’s Posi-Track undercarriage is unique in the industry. Rather than push the drive lugs on the inside of the track with a drive sprocket and teeth, ASV uses a series of rollers in a cage-like arrangement. Having rollers engage the lugs (rather than gear teeth) results in much less friction and a longer life for the drive mechanism.

Torsion bars suspend the undercarriage in front and back and rollers between them paired to a bogey system absorb much of the twisting and shock loading that transfers up from the ground. This design also keeps a maximum amount of track on the ground, improving tractive effort and lowering ground pressure.

The track itself is reinforced with poly-cord and stretches when obstacles or debris get between it and the undercarriage components. Storlie says this protects the track and the undercarriage components better than a steel reinforced track which cannot stretch and may damage rollers or sprockets when encountering hard debris. It also makes it less likely that the track will spool off.

The undercarriage is open, rather than shrouded in a protective enclosure. The open design allows debris to get in, but debris also quickly exit. By contrast in a shrouded system, debris builds up inside the shroud and acts like a lapping compound wearing away at the components and making clean out difficult.

ASV also makes this undercarriage system for Caterpillar’s multi-terrain loaders or MTLs.

For a look at how this system glides over obstacles and sheds debris see the video below.