All the D-series advanced technology plus a new cab design.

All the D-series advanced technology plus a new cab design.If you’re looking for more muscle and a comfortable-all-day cab environment, Caterpillar showed us two new models that fit the bill–the 297D and 297D XHP—at a press event in Clayton, North Carolina last week.

Judging by the numbers, the two machines punch well above their weight class.

The 279D increased its horsepower by four percent, torque rise by 13 percent and lift force by 19 percent. The 297 XHP comes out swinging with a horsepower boost of 17 percent, peak torque up 27 percent, lift force up 19 percent and 10 percent better rated operating capacity.

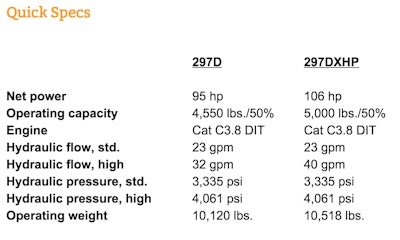

What’s more, to take advantage of Cat’s growing line of high-horsepower, high-flow work tools, the XHP model has an auxiliary hydraulic system with a relief pressure of 4,061 psi and 40 gpm. (Additional specs at the bottom of this article.)

The one-piece, D-series cab is all new. It’s sealed and pressurized and independent of the chassis for a smoother ride. Heat and AC were boosted 20 percent, helped by a new cooling system design that incorporates a hydraulically driven, on-demand fan.

Cat’s advanced display monitor (optional for the 297D, standard on the XHP ) can remember settings and information for up to 50 operators. The five-inch LCD display lets you make on-screen adjustments to the work tool response, hydrostatic drive response, and creep control. It also serves up machine diagnostic information and allows “master code holders,” (presumably the boss) to review operator-specific machine performance. The rearview camera is also displayed on the screen.

The D series changes started migrating into the Cat skid steer and tracked loader lineup in 2012, but if you haven’t heard about it yet, the series’ “intelligent leveling system” (ILEV), is worth mentioning. It works much like the advanced controls offered on many of today’s large wheel loaders, automatically leveling the load as the bucket or tool goes up or down. It also gives you a return-to-dig function so you don’t waste precious seconds feathering the bucket or tool down that last 12 inches to the ground. And a work-tool positioning function automatically returns attachments to a preset angle after you reposition the machine.

For you hard chargers out there, the new dial-type throttle is paired with a foot throttle pedal. The pedal functions as a decelerator when the dial is in high idle giving you a bit of extra control and safety. Both machines are vertical lift, to get you in closer to the truck or obstacles when loading.

Caterpillar MTLs (927D and 927D XHP included) are rubber-track machines, offering the lightest ground pressure of any of the undercarriage options. And there are four options in the skid-steer based machines:

- Tires for skid steers

- All-rubber tracks and rubber-coated rollers for the MTLs

- Steel reinforced rubber tracks for the compact track loaders

- The dozer-like all steel undercarriage

Which type is best for you?. Tires are typically best for paved and hard surfaces. The all-rubber track offers the lowest ground pressure to protect turf and give good flotation in mud or soupy conditions. The steel reinforced tracks also offer good flotation but are heavier and more aggressive–best suited for more abrasive and abusive conditions. For more on the most rugged option, the all-steel undercarriage, see our earlier report.