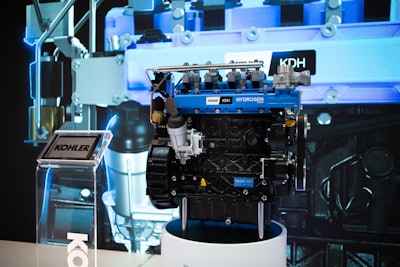

Kohler Engines has unveiled its new KDH direct injection hydrogen-powered internal combustion engine.

The announcement of the new product, expected to be available for order in 2026, builds off the news earlier this year that it is establishing Kohler Energy as an independent company,

The hydrogen engine is based on its KDI 2504 TCR derivative engine, which uses conventional combustion engine architecture but replaces diesel with hydrogen. From an environmental point of view, the combustion of a hydrogen engine is cleaner than a standard diesel engine.

Kohler says the KDH is intended to be a drop-in replacement for the diesel variant. OEMs can expect compatibility with existing machine platforms as the engine platform of the machine will keep the same cooling circuit, power take-off and flywheel, engine mounting points, and intake line.

Multiple components are shared between the KDH and KDI models, with primarily only the fuel line needing adjustment due to the change from diesel to hydrogen.

No major changes will be required to the engine compartment as the hydrogen option fits the current size engine envelope of Kohler compact diesel engines.

Using direct injection as opposed to port fuel injection allows the new engine to preserve diesel-level performance, including transient response, by avoiding any backfire problems.

Kohler says the intent is for the KDH engine to match the performance of the diesel model in max power, peak, and low-end torque, as well as transient response and drivability.

According to Kohler, when an aftertreatment system (ATS) is applied to a hydrogen internal combustion engine, the potential environmental benefits of using hydrogen are further amplified due to a further reduction of exhaust emissions.

The addition of the ATS reduces particulate matter (PM), nitrogen oxides (NOx), and hydrocarbons (HC) to negligible levels at the tail pipe, making the engine near zero emission per most agencies' definitions.

"We look forward to unveiling this evolving technology and working closely with our partners to drive innovation, sustainability, and decarbonization in the industry," says Vincenzo Perrone, president of Kohler Engines.