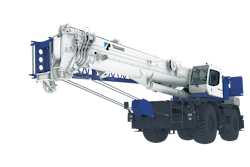

Tadano has launched the first of its new line of all-terrain cranes to combine the manufacturing expertise of its Zweibrücken and Lauf factories in Germany.

A two-axle crane, with a steerable rear axle and automatic programs for tight radii and crab steering, the Tadano AC 2.040-1 incorporates technology features that will inform the design of all future Tadano cranes. According to the company, these features will soon be found on 15 additional crane models to hit the market in the next few years. Upon completion of the announced brand merger, all Tadano Group cranes will be sold exclusively under the Tadano brand name.

The Tadano AC 2.040-1 hydraulic boom makes it possible to perform heavy lifts involving loads of up to 70,327 pounds without requiring additional sheaves.Tadano

The Tadano AC 2.040-1 hydraulic boom makes it possible to perform heavy lifts involving loads of up to 70,327 pounds without requiring additional sheaves.Tadano

Automatic counterweight detection, a capacity radar and a work area display are all part of the AC 2.040-1’s new IC 1 Plus control system. The system determines the crane’s lifting capacity for every boom position as a function of the superstructure’s slewing angle. This enables the AC 2.040-1 to make use of the maximum available lifting capacity with any outrigger configuration, including asymmetrical setups. When combined with the Flex Base system, this makes it possible to extend the outriggers to any point within their range.

The Tadano surround-view camera system shows both the maximum possible extension lengths for the outriggers and the counterweight tail-swing radius. As a result, it is significantly easier to position the crane for optimal performance. Additionally, the system improves safety on the way to the worksite by making it easier for crane operators to notice pedestrians and cyclists when turning.

Thanks to a Cummins 310-horsepower engine, the AC 2.040-1 can carry up to 2,425 pounds of counterweight while staying under an axle load limit of 13.2 tons. With a fully extended boom length of 115.5 feet at a radius of 26.3 feet, it can lift loads of up to 16,755 pounds.

The runner ensures fast and efficient work on jobsites and can be carried directly on the crane to the left of the main boom. And if the maximum main boom length of 115.5 feet is not enough, the crane’s range can be increased with a 29.5-foot extension that can be offset by up to 40 degrees.

The crane also comes with the IC 1 Remote telematics solution, which shows location remotely, and operating information and fault codes in-cab.