A forklift carrying steel rebar tipped over, crushing and killing a construction worker in Los Angeles on Monday, April 15.

The Los Angeles Fire Department responded to a call at 1:27 p.m. about an adult male trapped under a forklift at 970 N. Moraga Drive in Bel Air. Reports do not indicate whether the worker was operating the machine or near it at the time of the incident.

The worker, identified by the Los Angeles County Medical Examiner’s Office as 42-year-old Tony Gallegos, died on the scene from his injuries.

"Despite the quick response of LAFD crews, including those specially trained, certified and equipped for urban search and rescue operations, the adult male worker -- trapped beneath a toppled forklift that had been carrying steel rebar at a construction site -- proved beyond medical help," said Los Angeles Fire Department spokesperson Brian Humphrey.

No other injuries were reported on the site. Cal-OSHA will investigate the incident.

Aerial footage of the response can be seen in the KCAL News video below:

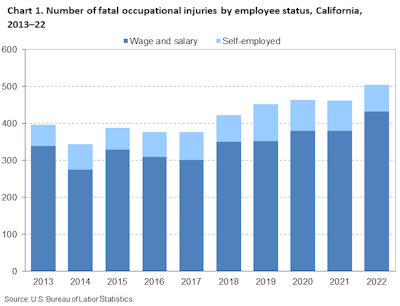

According to the U.S. Bureau of Labor Statistics, fatal work injuries have been on the rise in California since 2019, with 504 total fatalities in 2022. The construction and extraction occupational group had 80 fatal workplace injuries in 2022, the second-highest number behind only the transportation and material moving segment, with 132 deaths.

U.S. Bureau of Labor Statistics

U.S. Bureau of Labor Statistics

Forklift Safety Best Practices

According to United Rentals, operators should take the following precautions when operating rough terrain forklifts:

- Get trained: Start by taking an online course on rough terrain forklift operation. Operators can receive their certification after a live practical evaluation session.

- Wear your seatbelt: Wearing a seatbelt reduces your chance of injury or death in an accident.

- Inspect the machine before use: Look for cuts in the tires that could open up under the weight of a severe load and cause the machine to lean or tip. Look for any exposed steering components that may have come loose.

- Understand the load charts: When the boom is extended too far with too much load, it can easily tip over.

- Perform a hazard assessment: Walk the route you intend to take first to look for hazards, including people and objects. Properly adjust your mirrors before operation.

- Be realistic about the terrain: Ground conditions can change under the pressure of the machine and its load. The machine can easily get stuck in mud or soft terrain.

- Drive straight up or down a slope: Driving on a slope at an angle increases the risk of a rollover. Check the manufacturer’s limit to the slope and grade the machine is capable of traversing.

- Balance your loads: Open the forks wide enough to accommodate the size of the load and reduce the chance of tipping.

- Fight your instincts in the case of an accident: Do not attempt to jump out of the machine if it is tipping over. Firmly grip the wheel and brace yourself with your feet.

- Securely attach the load: Follow OSHA regulations when attaching a load. OSHA prohibits wrapping a chain or sling over the fork instead of using the lifting eye.

- Avoid carrying loads too high: A load should be carried as low to the ground as possible to reduce the risk of a tip-over.