Faced with a 300-foot-long sinkhole on U.S. 36 between Denver and Boulder, the Colorado Department of Transportation decided to use Geofoam blocks to rebuild the highway’s sunken foundation.

Cracks began forming on the five-year-old roadway in July, and within a week, the retaining wall for the road collapsed and wet clay soil underneath the road caved in. Three months later, the highway lanes were reopened.

CDOT hired Kraemer North America as the contractor for the $20.4 million emergency project. The project involved placing 6,100 blocks of Insulfoam Geofoam EPS22 polystyrene geo-synthetic fill.

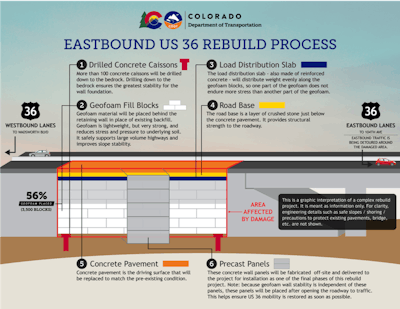

The project began with removing the collapsed wall from the top down and then removing 4 feet of dirt below the wall to be replaced. The Geofoam blocks were then placed.

A concrete load-distribution slab was placed above the Geofoam, then came a layer of crushed stone followed by concrete pavement.

A permanent wall of precast concrete panels was later added for stability for the Geofoam section. The wall is anchored by more than 100 caissons drilled into bedrock.

A permanent wall of precast concrete anchored by more than 100 caissons drilled into bedrock is built beside the Geofoam blocks to stabilize them. Photo credit: Colorado DOT

A permanent wall of precast concrete anchored by more than 100 caissons drilled into bedrock is built beside the Geofoam blocks to stabilize them. Photo credit: Colorado DOTThe lightweight Geofoam places less pressure and stress on the underlying soil, the CDOT says. And it is strong enough to support the highway while also stabilizing the slope. CDOT said this was the best safety option while also allowing it to reopen the highway’s six lanes as quickly as possible.

Insulfoam says the project threw its plants into high gear to meet the CDOT’s demand. The company sent 200 truckloads of Geofoam to the site over 20 days.

The collapse of U.S. 36. Photo credit: Colorado DOT

The collapse of U.S. 36. Photo credit: Colorado DOTThe company pulled from its six plants in Aurora, Colorado; Mead, Nebraska; Phoenix, Arizona; Lakeland, Florida; Puyallup, Washington; and Dixon, California. The blocks were customized to the project, in sizes of 40 inches by 48 inches by 96 inches. “These large block sizes can be produced to fill huge volumes, saving additional time and labor on the Colorado jobsite,” the company says.

“We went from 0 to 100 mph in an instant,” says Kris Essex, territory sales manager for Insulfoam in Colorado.

This graphic shows the steps taken to rebuild the collapsed section of U.S. 36. Graphic provided by Colorado DOT

This graphic shows the steps taken to rebuild the collapsed section of U.S. 36. Graphic provided by Colorado DOT