‘Bio-Binder’ Green Modifiers Star at TRB

By Tom Kuennen, Contributing Editor

More than 11,700 transportation professionals from around the world enjoyed over 4,000 presentations in nearly 750 sessions and workshops. Here are some of the most significant papers involving bio-based modifiers and other themes of interest to the roadbuilding community. For more information, visit www.trb.org.

Performance in Asphalt Mixes

Because they fall under the umbrella of organic chemistry, strictly speaking, any petroleum-based binder or modifer might be considered a “bio-binder.” However, today the “bio” prefix is reserved for binders and modifiers derived from processed biomass or biowastes, thereby earning them “green” status.

Mixes containing “bio-binders” – when used in conjunction with conventional asphalt binders – exhibit performance very similar to regular asphalt mixes, but with the benefit of being environmentally sustainable, write Louay N. Mohammad, Mostafa A. Elseifi, Samuel B. Cooper III, and Harshavardhan Challa, Louisiana Transportation Research Center, Louisiana State University, and Prem Naidoo, Green Asphalt Technologies, Pass Christian, Miss., in their paper, Laboratory Evaluation of Asphalt Mixtures Containing Bio-Binder Technologies.

Bio-binder is an alternative asphalt binder made from non-petroleum-based renewable resources. The use of bio-oil as a replacement to petroleum-based asphalt binder has been proposed in recent years, they say. “Bio-oils have distinct advantages when compared to fossil fuel oils,” the authors write. “Bio-oils are renewable, environmentally friendly, provide energy security, and can be an economic opportunity for the United States.”

In most cases, say Mohammed, Elseifi, Cooper, Challa and Naidoo, the feed stocks for bio-based materials do not compete with food or feed supplies. Bio-based materials include industrial products, co-products, and byproducts made from agricultural or forestry feed stocks, they say. These feed stocks could be wood, wood waste and residues, grasses, crops, and co-products of crops.

Technologies for converting biomass to energy can be generally classified into either biochemical conversion or thermochemical conversion, they say. Biochemical conversions such as anaerobic digestion and fermentation typically involve large facility footprints and long processing time, on orders of days or months, and pose potential threats to surface or ground waters.

“However, thermochemical conversions, including pyrolysis, gasification and hydrothermal liquefaction, feature more compact facility size and faster reaction (usually in order of minutes) when compared to biochemical conversions,” they write.

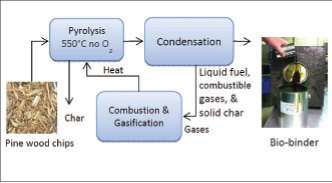

The bio-binder considered in this study was produced by fast pyrolysis of biomass, say Mohammed, Elseifi, Cooper, Challa and Naidoo. During fast pyrolysis, biomass is heated rapidly in a high temperature environment (Fig. 1).

The resulting product is a mixture of liquid fuel (bio-oil), combustible gases, and solid char. Bio-oils produced by fast pyrolysis have many industrial uses, which include: combustible fuel, liquid smoke, preservative, base for chemicals and resins, binder for combustible fuel starter and briquettes for boilers, or an adhesive.

Fig.1: Biomass pyrolysis for production of bio-binder.

Fig.1: Biomass pyrolysis for production of bio-binder.“The binding properties of the material are desirable for use in asphalt pavements,” they say. “Typically, [in practice] bio-binders are a combination of petroleum asphalt cement and bio-oils. Bio-binders are used to reduce the demand for petroleum-based bituminous binder in three ways: direct replacement (100 percent replacement), an extender (25 to 75 percent replacement), or a modifier (<10 percent replacement). Applications of bio-binder range from asphalt paving to roofing shingles to sealants.

“Several research studies have evaluated the viability of bio-binders in asphalt pavements,” they say. “However, in many of these cases the bio-binder was evaluated in minimal proportions (<10 percent). In addition, much of the research evaluated manure, oak tree and switch grass feed stock. There is a need for a comprehensive laboratory evaluation of mixtures containing bio-binder from alternative feed stocks at higher blending proportions (up to 50 percent replacement).”

This study determined if asphalt mixtures prepared with high bio-binder content from pine tree feed stock have the potential for increased use in transportation infrastructure. The researchers conducted a comprehensive laboratory evaluation of asphalt mixtures containing bio-binder technology at a content of 20, 25.5, 30 and 50 percent.

Attributes of Bitutech RAP as provided by marketer

Attributes of Bitutech RAP as provided by marketerThe mechanistic properties of asphalt mixtures containing green asphalt technologies were evaluated in comparison to conventional asphalt mixtures. A suite of laboratory tests was conducted to capture the mechanical behavior of the mixtures against major distresses.

“Laboratory testing evaluated the rutting performance, moisture resistance, fracture performance, and low temperature resistance of the produced mixtures using the Hamburg loaded-wheel tester, the modified Lottman test, the semi-circular bending test, and the TSRST [thermal stress restrained specimen test].”

Based on the results of the experimental program, the researchers conclude:

• With respect to rutting performance, mixtures modified with [this] green asphalt have shown similar or improved performance when compared to the conventional mixes.

• The mean rut depths of the mixtures containing PG 64-22 and PG 76-22 [binders] were significantly improved with the addition of bio-binder. In addition, all the mixtures did not experience tertiary flow or passed the stripping inflection point, indicating moisture susceptibility.

• All mixtures, except for two, including one without an anti-stripping agent, exceeded the 80 percent tensile strength ratio. An anti-stripping agent was used for only one mixture comparison, 64-22. After the addition of the anti-stripping agent, the tensile strength ratio of those two mixes exceeded 80 percent.

• There were no significant statistical differences associated with the addition of bio-binder.

• The mixes containing bio-binder exhibited reduced intermediate temperature fracture resistance as compared to conventional mixes. This may be due to the stiffening effects of bio-binder on the mix. But the results for the PG 70-22 comparison were significantly different, and

• Bio-binder asphalt modification improved the low temperature fracture performance of the mixtures when compared to conventional mixtures of similar performance grade.

Improving RAP Mixes

Bio-binders improve the elasticity, hence performance, of bituminous mixes containing reclaimed asphalt pavement (RAP), say Elie Y. Hajj, Ph.D., Western Regional Superpave Center, University of Nevada-Reno, Mena I. Souliman, Ph.D., and Mohammad Zia Alavi, Department of Civil and Environmental Engineering, UNR, and Luis Guillermo Loría Salazar, Ph.D., Laboratorio Nacional de Materiales y Modelos Estructurales, Universidad de Costa Rica, in their paper, Influence of Hydrogreen Bio-Asphalt on Viscoelastic Properties of Reclaimed Asphalt Mixtures.

“’The inclusion of reclaimed asphalt pavement (RAP) into new asphalt mix design is becoming more popular due to the rising cost of oil, limited amount of quality virgin materials and limited space in landfills,” the authors write. “However, incorporating RAP exposes some challenges from the design perspective since the asphalt binder in RAP becomes stiffer because of aging.”

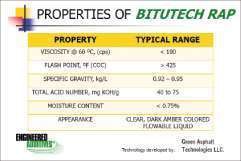

This stiffness can be addressed via use of rejuvenating additives, and the paper describes the lab evaluation of an existing bio-based rejuvenating agent, called BituTech RAP.

High content RAP mixtures used in Manitoba were evaluated to study BituTech RAP’s impact on the viscoelastic properties of asphalt mixtures to overcome any possible moisture damage – or thermal cracking problems – that may arise in such a wet-freeze environment.

“The laboratory testing consisted of producing mixtures containing 15 and 50 percent RAP, with and without BituTech RAP,” they write. “Mixtures were tested using the dynamic modulus test as well as thermal stress restrained specimen test.”

Even though RAP use has been specified by multiple highway agencies, the potential issues with binder and mixture stiffening prevented various states from using higher percentages (greater than 30 percent) of RAP in hot mix asphalt (HMA), they say. “This stiffening behavior is function of the age of the RAP material and the compatibility between the virgin and reclaimed asphalt binders,” they write. “Consequently, the mixture durability and resistance to fatigue and thermal cracking may be reduced, resulting in a poor pavement performance.”

The increased stiffness of the RAP binder is believed to be the cause of increased modulus, or stiffness, of the asphalt mixture, they say. “Likewise, the use of high RAP contents was found to possibly affect fatigue behavior and low-temperature cracking properties of asphalt mixtures,” they add.

Rejuvenating agents have been traditionally used to offset the high stiffness of the aged RAP binder, and use of rejuvenating agents could possibly increase the durability and the low-temperature performance of mixtures containing RAP without jeopardizing the overall performance of the mixture, they state.

“One such bio-asphalt additive is BituTech RAP, also sold under the brand name Hydrogreen, developed by Green Asphalt Technologies as an alternative to carcinogenic aromatic oil rejuvenants,” say Hajj, Souliman, Alavi and Salazar. “BituTech RAP is a unique combination of selected natural plant extracts reacted in a distinct process to create a powerful asphaltene dispersant. It is intended to offer maltenes without an aromatic content in order to eliminate environmental concerns associated with using oil based products.”

To investigate, an extensive laboratory evaluation was conducted to study the effect of BituTech RAP on asphalt mixtures containing RAP up to 50 percent. The impact of RAP content and BituTech RAP on dynamic complex modulus, moisture damage and thermal cracking resistance of HMA mixtures were evaluated using advanced testing techniques.

Based on the analysis of the data generated in this study, the researchers find:

• Cole-Cole analysis showed that the loss modulus (E”) values for mixtures with BituTech RAP were significantly higher than the ones without. In addition, the performance of mixture with 50 percent RAP with BituTech RAP was similar to the mixture with 15-percent RAP with the additive. Hence, HMA mixtures with high RAP percentages (up to 50 percent) can be used with BituTech RAP without sacrificing the performance of the mixture.

• Adding BituTech RAP to the RAP mixtures improved their resistance to moisture damage after three freeze-thaw cycles. Mixtures with BituTech RAP exhibited storage modulus and loss modulus values that are significantly higher than the mixtures without BituTech RAP.

• For the thermal stress restrained specimen test (TSRST), the addition of BituTech RAP restored the low temperature properties of the RAP mixtures. A reduction in the relaxation modulus was observed with a shift in the fracture temperature, micro-cracking initiation temperature, and viscous-glassy transition temperature to the colder side.

• A cost analysis showed potential savings for using BituTech RAP with 50 percent RAP besides its effect as a rejuvenating agent. Using BituTech RAP [can] promote using higher percentages of RAP without affecting the overall performance of the mixture.

Cement-Limestone Blends Benefit Concrete Performance

There are profound benefits in performance and sustainability of concrete structures made with portland cement blended with limestone, but careful attention must be given to the fineness of the limestone portion, say V. Tim Cost, P.E., Holcim (US), and Isaac L. Howard, Ph.D. and Jay Shannon, Mississippi State University, in their paper Integrated Improving Concrete Sustainability and Performance Using Portland-Limestone Cement (PLC) Synergies.

The use of fine-ground limestone as an adjunct to portland cement – with little to no change in performance with the blend – has been supported by the cement industry, as it permits increases in product shipped without a corresponding expansion of plant capacity, with all the environmental permitting required. While the cement industry has drifted toward portland-limestone cement (PLC) blends, the recent inclusion of PLC – a cementitious blend of portland cement – in the ASTM and AASHTO specification canons mean PLC is going mainstream.

Published research has documented performance synergies of cementitious mixtures with finely ground limestone (particle sizes generally smaller than for cement), especially in combination with certain supplementary cementitious materials (SCMs)

PLC is similar to ordinary portland cement, but it also contains a specific minor fraction of finely ground limestone particles, the authors say, and can be produced at any portland cement manufacturing plant. For this, crushed limestone is metered along with clinker and gypsum to the finish grinding mill.

“The sources of limestone typically used in cement making as a raw material are ideal for the limestone used in PLCs, thus no additional special materials must be acquired,” say Cost, Howard and Shannon. “Limestone is softer than clinker and grinds more easily, so the limestone particles in finished PLC are generally finer than the ground clinker, which favorably effects the overall particle size distribution of the cement.”

Compared to conventional portland cement, PLC measurably improves concrete sustainability through the reductions of greenhouse gas emissions associated with cement production (by roughly the percentage of limestone used) and by the lower embodied energy of the cement, they add.

“Increased use of portland-limestone cements in the U.S. is anticipated, as a new provision for PLCs containing up to 15-percent limestone has been added to blended cement specifications,” the authors write.

Specifications for blended cements under ASTM C595 and AASHTO M 240 now include provisions for Type IL cements (PLCs) containing up to 15 percent limestone as well as Type IT cements containing combinations of limestone and pozzolan or slag.

Synergie have been found, however, to occur under specific circumstanced.

Published research has documented performance synergies of cementitious mixtures with finely ground limestone (particle sizes generally smaller than for cement), especially in combination with certain supplementary cementitious materials (SCMs), they say. “Time of setting and strength development benefits are reported, generally in proportion to limestone fineness,” the authors write.

“It appears possible to fully develop potential for these performance synergies in mill-ground PLCs, in which limestone comprises the majority of the finest particles.”

For this research, performance trends observed in concrete with PLC were investigated using separately proportioned, commercially ground limestone and ordinary portland cement , as well as cement mill-ground PLC samples.

Influences of variables such as SCM type and limestone fineness were also evaluated using laboratory paste mixtures.

“Set acceleration increased with limestone fineness for all combinations, including mixtures without SCMs,” say Cost, Howard and Shannon. “Strength improvements were clearly evident with all SCMs, more significantly with Class C ash and slag cement than with Class F ash. All strength trends improved as limestone fineness was increased.”

Consistently enhanced setting and strength performance appear achievable with PLCs, they say. “Optimizing particle fineness will be a key factor in achieving these benefits,” they add. “Performance contributions of SCMs in combinations with PLCs may exceed those of similar mixtures with traditional portland cements, thus SCM use can be maximized and related sustainability impacts further extended.”

The authors conclude:

• Portland-limestone cements produced at up to 15 percent limestone have the potential to significantly improve concrete sustainability, with performance at least equal to – and often superior to that – of conventional cements.

• Properly optimized, portland-limestone cements clearly hydrate with synergies contributed by limestone that enable enhanced setting and strength performance, especially in combination with SCMs.

• The extent of PLC performance benefits relates to limestone fineness; clinker fineness approaching that of conventional cements must generally be maintained in the composite PLC.

• The particle size distribution of PLC, produced to optimum overall fineness in finish grinding ball mills, appears well suited for synergy-driven performance enhancement.

• SCM use in concrete with PLC, to the maximum levels that are allowed with conventional cement, must be allowed and encouraged in order for the greatest possible sustainability and performance benefits of PLC to be achieved.

• Higher-than-traditional replacement rates with some SCMs appear possible without loss of performance, further extending the sustainability benefits of PLCs.

Environmentally Sustainable Preservation

Today’s pavement maintenance and preservation practices minimize their environmental impact and thus are environmentally sustainable, according to Sustainable Pavement Maintenance and Preservation Practices: A Review of Current Practice, by Dr. Susan L Tighe, P.Eng., University of Waterloo, Ont., and Dr. Douglas Gransberg, P.E., Iowa State University-Ames.

“Pavement preservation promotes environmental sustainability by conserving energy, virgin materials, and reducing greenhouse gases by keeping good roads good,” the authors say. “Therefore, the foundation of a sustainable pavement maintenance program is to commit personnel and resources to pavement preservation.”

Pavement preservation promotes environmental sustainability by conserving energy, virgin materials, and reducing greenhouse gases by keeping good roads good.

– Sustainable Pavement Maintenance and Preservation Practices: A Review of Current Practice

Tighe and Gransberg summarize seven sustainability impact factor areas, including virgin material usage, alternative material usage, program for pavement in-service monitoring and management, noise, air quality/emissions, water quality and energy usage; and evaluate their relationship to typical pavement preservation and maintenance practices (the United States administration differentiates between pavement maintenance and preservation, while the Canada administration does not).

The authors conclude:

• Environmental sustainability research specific to post-construction operations is an emerging (but not established) field.

• Thin asphalt overlays are the most prevalent treatment for asphalt and composite pavements.

• Diamond grinding and joint sealing are the most commonly used for concrete pavements.

• Regrading and regraveling are the most prevalent treatments for graveled roads, while chip seals are the preferred treatments for surface-treated roads.

• Quantification of environmental sustainability with pavement preservation and maintenance programs is not commonly practiced in the United States and Canada.

• Various construction and design environmental sustainability initiatives are available in the literature. However, an assessment tool to properly quantify environmental sustainability in the pavement preservation and maintenance context is required.

• Environmental sustainability metrics should be developed and integrated into pavement preservation and maintenance treatment programming.

They identified a number of future research needs in quantifying the environmental sustainability of maintenance and preservation. Those needs include:

• pavement preservation- and maintenance-specific research to furnish agency engineers with fundamental quantitative data on the relative environmental sustainability of common treatments.

• development of a pavement preservation and maintenance specific lifecycle assessment and cost analysis method that includes values for factors such as carbon footprinting, resource renewability, and other salient elements of environmental sustainability, to furnish a rational approach to treatment selection.

• research quantify the importance of preservation and maintenance treatments in environmental sustainability impact areas.

• complete research in adapting recycled and alternate materials for use in pavement preservation and maintenance treatments.

• research to identify and develop appropriate noise standards for pavement preservation and maintenance operations and life cycle assessment.

Slurry surfacings provide durable pavement preservation treatments that can be environmentally sustainable, research indicates

Slurry surfacings provide durable pavement preservation treatments that can be environmentally sustainable, research indicates• research to quantify the contribution that crack sealing makes to environmental sustainability of all types of pavement surfaces, and

• research policies, technology, materials, specs, standards, equipment, capacity-building, recycling/waste reduction, emissions reduction (air pollution) and life cycle cost analysis.

“In this regard, it is necessary to incorporate sustainable pavement maintenance elements into on-going and future pavement maintenance research,” they conclude.

Permeable Asphalt and ‘Heat Islands’

Permeable asphalt pavements can help urban areas reduce the local “heat island” effect – enhancing livability – but the impact depends on ambient conditions, say Hui Li, John Harvey and David Jones, University of California Pavement Research Center, University of California-Davis, in their paper Cooling Effect of Permeable Asphalt Pavement under Both Dry and Wet Conditions.

Permeable pavement contains more voids than conventional impermeable pavement and is designed to allow water to drain through the surface into the sublayers and down into the ground below. Permeable pavements include permeable asphalt pavements, porous concrete pavements, pervious cast concrete pavement, and interlocking concrete pavements, they write.

Permeable pavements include

permeable asphalt pavements, porous concrete pavements, pervious cast

concrete pavement, and interlocking

concrete pavements

“Through field measurements on pavement test sections with both conventional and alternative designs, the thermal behavior and cooling effect of permeable asphalt pavements under both dry and wet conditions were investigated,” say Li, Harvey and Jones .

The researchers found the overall seven-day average cooling effect of wetting once on permeable pavements for near-surface air is approximately 0.2 to 0.45 degrees C [0.36 degrees F to 0.81 degrees F]; for the surface it is approximately 1.2 to 1.6 degree C [2.16 to 2.88 degrees F]; and approximately 1.5 to 3.4 degrees C [2.7 to 6.12 degrees F] for the in-depth layers.

“Based on the findings, permeable asphalt pavements have the potential of being a type of cool pavement which produces lower temperatures and thus helps improve the thermal environment and mitigate the heat island effect,” they write. “However, attention should be given to this type of pavement under dry conditions. As a pavement thermal management strategy, water from rain or irrigation systems might need to be applied to the pavements to produce a better cooling effect for improving the thermal environment and mitigating the heat island.”

These permeable pavements can be used in city streets, parking lots and highway shoulders, and the type of surface could potentially enhance the evaporation from pavement, while the cooling effect depends on the moisture content and evaporation rate, they say.

“Beyond reducing temperature, permeable pavements also could potentially reduce the air/pavement noise due to reduced air pumping under high speed, and improve high-speed driving safety through reducing splashing and hydroplaning during rain,” they say. “Also, full depth permeable pavement could reduce stormwater runoff and improve water quality. However, permeable pavements also could possibly increase fuel consumption of vehicles due to higher rolling resistance caused by the rougher surface.” Permeable pavements are possibly not suitable for high speed and heavy-duty facilities such as highways and airfields due to their relatively lower structural capacity, they add.

The issue of whether rigid (white) or flexible (black) pavement is the “coolest” pavement medium has been raging for years between the portland cement concrete and the bituminous concrete industries. The authors address this issue, saying it’s not so simple.

“With respect to the pavement type, the heat island might not be a ‘black and white’ issue (asphalt vs. concrete) as being argued in the pavement industry, but might be an ‘impervious and pervious’ issue,” they say. “To mitigate heat islands and reduce the associated impacts, some impervious surface coverage should be substituted by pervious coverage.”

The minimized impervious surfaces could potentially improve the quality of life in a community and reduce other environmental impacts, such as reduced stormwater runoff and associated water pollution, reduced stormwater management facilities, and enhanced on-site infiltration for vegetation growth, recharging the underground water, they say.