On December 18, the federal government will require drivers of a broad selection of construction, vocational and on-highway trucks to record their drive times on electronic logging devices (ELDs).

The ELD mandate comes from the Federal Motor Carrier Safety Administration. It is designed to replace paper driver logs with electronic versions that will be harder to fudge and reduce the number of tired and sleep-deprived truck drivers on the road.

As we first reported in June, the legal requirements for construction and vocational trucks are convoluted. In addition to the ELD mandate, the FMCSA ruling dictates new hours of service (HOS) regulations, which prescribe how many hours any truck driver can operate a vehicle – regardless of whether he or she needs to maintain an ELD. If this is all new to you or you’re not sure your drivers will be required to maintain an ELD, start with the link above.

As if that isn’t complicated enough, the law doesn’t appear to be completely set in stone as we were going to press. The FMCSA granted the Specialized Carriers and Riggers Association an exemption to a small part of the HOS rules this spring. And late this summer, the National Asphalt Paving Association petitioned the agency for similar exemptions for its members, but there has been no ruling on that as of press time. HOS rules were also waived in August and September for trucks traveling in and out of the hurricane-damaged regions on the Texas-Louisiana coast and in Florida. And vigorous protests against the law are popping up with increasing frequency.

Still, in all likelihood, the law will stand and take effect December 18. You should be prepared. Read the rules. If you don’t need to use an ELD, carry on. If you do need one, however, and get caught without, the violation could result in an out of service violation, mandatory shut down, fines of anywhere from $1,000 to $10,000 and a hit to your CSA scores.

In the sections that follow, we provide a new and updated chart showing most of the ELD providers that have come into the market since our original story in June. But if you’re in the market be sure the check out both charts.

The benefits of telematics

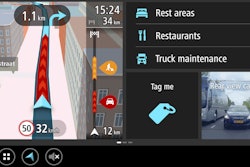

If there is a silver lining in all of this, it is that the ELDs are also telematics devices, and aside from keeping you on the right side of the law, they’re great tools for managing and monitoring your trucks.

“Instead of viewing compliance as a costly burden, the ELD mandate represents a chance for companies to make significant, long-lasting improvements through a few key investments,” says Fred Fakkema, Zonar’s vice president of compliance.

“These solutions provide visibility into fleet operations that can drastically improve fuel efficiency, driver safety and profitability,” says Paul Miles, segment manager for Trimble Field Service Management. “Being able to share information between drivers and dispatch, reroute trucks to avoid traffic, capture diagnostic information from a truck’s engine, and manage day-to-day fleet operations remotely is a game changer when it comes to improving job scheduling and making business decisions.”

Ryan Driscoll at GPS Insight notes that ELDs and telematics help reduce high CSA scores, which in turn, lead to lower insurance premiums. Additionally, customers can monitor the location of their vehicles 24/7, which can lead to more accurate billing and help prevent theft or enable quick recovery if a truck or trailer is stolen. Electronic logs and telematics also enable you to move to a paperless management system for improved and more accurate recordkeeping, he says.

With the December 18 deadline looming, construction fleets won’t have time to conduct extensive trials.

“These fleets should have already bought something and be in the training phase so they are running legally by the deadline,” says Driscoll. Rather than field trials, Driscoll recommends in-depth demos to see both the driver interface and the management interface of the ELD system you are considering. This will help you understand how easy or complicated the system is to use.

ELD solutions should integrate with other systems to avoid disparate solutions haphazardly trying to work with each other, says Fakkema. Fleet managers should stick with one system in which their solutions work in unison.

Fakkema pinpoints seven ways ELD telematics can improve fleet management:

1. Effective use of assets within a fleet – Project managers can maximize all assets to avoid unnecessary sourcing of equipment.

2. Automatic data – Many construction fleets rely on meter data to maintain vehicles daily. Often, this is manual. Telematics can collect this data automatically.

3. Visibility into preventive maintenance – Remote diagnostics, shop resources, uptime and scheduled preventive maintenance are all possible with telematics.

4. Maximize cycle times and uptime – Telematics can identify the most effective routes and use of equipment.

5. Fuel efficiency – Use data to monitor idle times, speed, acceleration, hard braking and more to improve fuel usage.

6. Electronic verified inspection reporting – Ensure that federally required daily vehicle inspections occur.

7. Protect against theft – Telematics-enabled tracking locates assets in real time, which can pinpoint a piece of equipment’s location immediately.

Use the scrollbar at the bottom of the chart to move left and right to see more data.