Quantum Leap

Is it really possible to build a truck that is 50 percent more fuel efficient in the next five years? The new SuperTruck program intends to find out.

By Jack Roberts

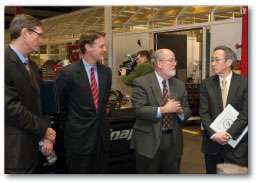

Left to right: Tom Linebarger, Cummins president and chief operating officer, Senator Evan Bayh, Dr. John Wall, Cummins vice president and chief technical officer and Dr. Stephen Chu, Secretary of the Department of Energy.

Left to right: Tom Linebarger, Cummins president and chief operating officer, Senator Evan Bayh, Dr. John Wall, Cummins vice president and chief technical officer and Dr. Stephen Chu, Secretary of the Department of Energy.In January, U.S. Department of Energy (DOE) Secretary Steven Chu announced the initiation of the SuperTruck Project and the selection of three projects that would receive $115 million in government funding to improve fuel efficiency for heavy-duty trucks and passenger vehicles. The funding includes money from the American Recovery and Reinvestment Act that, with grant recipients kicking in 50 percent of the cost, will support about $230 million in projects across the country.

“The goal of the SuperTruck Program is to further improve tractor-trailer efficiency by 50 percent,” says Hannes Moeller, chief engineer, product validation engineering, Daimler Trucks North America. “This includes a goal of improving engine efficiency by 20 percent, which is a significant challenge given today’s diesel engines are among the most efficient and lowest emission engines available.”

“It’s no secret the national academy of sciences has been studying Corporate Average Fuel Economy (CAFE) standards that apply to autombiles and looking for away to apply them to the heavy-duty trucking industry,” says Landon Sproull, Peterbilt chief engineer. “They’ve spoken to us at Paccar and all the other OEMs, as well as fleets, and they’re trying to figure out how to find ways to drive higher fuel economy standards for the trucking industry.”

According to DOE guidelines, participant companies, including Damiler Trucks North America, Navistar and Peterbilt, will be asked to develop different technologies that will result in a 50-percent increase in fuel economy (in ton miles) at road speeds pulling a 65,000-pound load. “But, a certain percentage of this 50 percent goal has to come from the engine, or powertrain, side according to the DOE,” says Ed Anesi, vice president of advanced technologies for Navistar. Although a certain amount of the new technology can come from chassis or body improvements (such as weight reduction or aerodynamics), the DOE wanted to make sure that we just didn’t just throw on some aerodynamic devices and be done with it. They are looking for core engine technology changes.”

“Many of the technologies in the SuperTruck program are stretch technologies at this time,” Moeller adds. “So even if the 50-percent efficiency improvement goal can be achieved, not all of the technologies will ultimately be cost-effective enough for production vehicles. Part of the SuperTruck program is to develop the technologies in such a way as to hopefully knock down cost barriers and make these technologies more affordable and available in the future.”

“There isn’t just one silver bullet approach to attain that 50-percent fuel economy mark,” Jadin adds. “At Navistar, we have multiple technologies we are applying to this solution. We understand many of them will not pan out – although ultimately we believe we will hit that 50-percent target.”

How they’ll get there

Companies receiving funding include Daimler Trucks North America, Cummins, Navistar and Peterbilt. Many of these companies, in turn, have developed partnerships with Allison Transmission, Bridgestone/Firestone, Delphi, Eaton and Robert Bosch. These companies will also receive funding and help develop specific technologies designed to move truck technology forward.

Each OEM submitted proposals to the DOE and could request a maximum of $40 million, which the company would then match, dollar for dollar.

The ultimate goal in the end for each of the three major OEMs receiving Federal money is a physical, deliverable truck to the DOE five years from now. Each of those three 21st Century Trucks will go through a battery of standardized tests to validate the success of the individual solution packages.

The good news for truck owners, however, is that any advances uncovered as SuperTruck proceeds will not be withheld until 2015. New, fuel-saving technologies will be rolled out as soon as they become available. In fact, Navistar will unveil the first of its SuperTruck innovations next month at the Mid-America Truck Show in Louisville, Kentucky.

How will they get there?

Because of the structure of the DOE guidelines, truck manufacturers must use separate technologies. Peterbilt, for example, has partnered with Cummins to work on engine technology, which will target powertrain improvements, refined fuel injection and combustion as well as seek ways to improve a diesel engine’s waste heat recovery characteristics. Navistar and Daimler subsidiary Detroit Diesel indicate their diesel engine research will be along similar lines.

Daimler is not commenting on any specific areas of technology at this time. But Moeller does note that research will focus on developing “superior” technologies in engine emissions and electrical systems; tractor-trailer aerodynamics; alternative drivetrains; predictive technologies; as well as chassis, cab and tractor components.

According to Sproull, Peterbilt’s additional SuperTruck efforts will target aerodynamics, developing lower rolling resistance tires through another partnership with Bridgestone/Firestone and leveraging another partnership with Delphi to develop Peterbilt’s new fuel cell technology program to reduce engine idling times.

“Our first generation fuel cells are complete,” Sproull says, “and we’re taking what we learned as we work on the second generation of this technology. Our next step is to begin developing ways to integrate fuel cells into the tractor trailer.”

Navistar’s approach will target further hybridization of heavy-duty powertrains as a way to increase fuel economy – although aerodynamics, chassis weight reduction and improved combustion and thermal efficiency in the engine will play equally important roles. “Right now, after an electric launch, the diesel engine typically takes over and powers the vehicle around 15 mph on a Class 5 truck,” Jadin notes. “Our goal is to develop larger, more robust hybrid powertrains that can withstand the rigors of Class 8 trucking applications while raising the launching speed where diesel power takes over significantly.”

Cummins will focus on making diesel engines more efficient, primarily through refined combustion techniques and waste heat recovery. “We have been working on many of these approaches for the past six years,” says Dr. Vinod Duggal, director, strategic planning and advance engineering for Cummins. “So we are not attempting to launch a whole new engine family. Instead we will enhance our current heavy-duty engines with this new technology.”

Cummins believes diesel engines, which are currently around 42-percent efficient, can be improved by as much as 15 percent over the next five years. “Our main challenges will be to decide how best to use that energy on the truck,” says Wayne Eckerle, vice president of corporate research and technology for Cummins, “either as stored power for auxiliary systems or motive power while keeping overall vehicle weight down and maintaining 2010 emissions levels.”

Peterbilt, Navistar and Daimler will all work on enhancing tractor-trailer aerodynamics, which Sproull says can potentially provide up to a 10 to 15 percent improvement in aerodynamic qualities, resulting in a 5 to 8 percent jump in tractor-trailer fuel economy. EW