“Whatever it takes” on the surface may bring up thoughts of driving a square peg through a round hole with an enormous hammer, but for Al Gorick, it signifies a philosophy that a job will be done the right way, no matter what resources are needed. The slogan is part of Gorick Construction’s logo, and appears on its website as well as the company’s clothing.

Gorick grew up in the construction business, working summers at the company. His parents started the company in 1945, following his father’s return from World War II, serving under Gen. George S. Patton. It was such a family business that his mother and father bought the company’s first dump truck on their honeymoon.

“They drove to Atlantic City, New Jersey, and bought a dump truck,” Gorick laughs in describing the beginnings of Gorick Construction. “She drove the car home and he drove the dump truck home.”

The youngest of four children, and the only son, Gorick went to work as soon as he could as a child, starting with cleaning bathrooms and advancing to heavier tasks. He also learned a few valuable lessons about limitations as he progressed.

“I broke my toe changing truck tires when I was about 12,” he says. “I dropped a truck rim on my foot. I knew better, but it’s just that I couldn’t get the rim out of the tire, so I kept at it, and it just fell out. So I’ve had some bumps and bruises along the way, but you learn.”

But when he went to college, majoring in civil engineering, he was determined to strike out on his own, rather than falling back on the family business.

After graduating from Clarkson University, Gorick interviewed with several companies, as well as the Connecticut Department of Transportation. Four offers came, he says, even with the companies knowing he had a job at a family business waiting for him. He was waffling a bit on the decision, though.

“I wasn’t sold at that time if I was just going to come here or not. But I was determined that I was going to do it on my own, if I did. If I came here, it was going to be ‘OK, you’re hiring me here,’ as opposed to me going to work for another firm.“

Changing leadership

Gorick quickly set his mind to stay home and joined the company full-time after graduating.

“There was no time off. I was going to come back and make sure that we moved ahead and do what we had to do,” he says. “So at that point, I was going out and running machines during the day and coming back and doing bidding work at night, then taking care of phone calls at lunch.”

He was determined Gorick Construction was going to grow at that point, confident that the quality people and the resources the company had would help him achieve that goal. He became president of the company just two years later.

“We had to either get a little bit bigger, or we had to go smaller, but we couldn’t stay where we were, because we were going to get pushed out,” he says. “So we went after some bigger jobs.”

The first of these jobs was a $1 million-plus project on the nearby I-81/I-88 bridge connector involving moving more than 400,000 cubic yards of dirt for the embankments and ramps.

“I was going to prove to my father that getting the bigger jobs made sense,” he says. “He thought it was too much for us to take on at that time. But it worked out well, fortunately.”

Gorick attributes his drive for growth to his mother, who he describes as being the administrative and business side of the company versus the “worker” that his father had always been.

“Anything to deal with paying bills, taxes, unions, lawyers, that was all her,” he says. “I never knew a man that worked harder than my father, but if it was just him without her, it would have still been a dozer, backhoe and a dump truck show, and that’s it.“

Challenges build character

A major challenge early on in Gorick’s career, however, gave him an opportunity to test his resourcefulness and ability to turn a potential bad situation into a win.

An environmental legal battle over a construction debris landfill the company owned represented a major crossroads for Gorick. But the company persevered and used its experience to cap and close the site.

“This was the most difficult business situation that I had to endure, and it happened to coincide with my mother’s passing,” he says. “We conquered this huge obstacle, this environmental lawsuit that could have put us out of business. I remember a family friend, who is a federal judge, telling me at the time that this environmental lawsuit would be the hardest thing I would ever have to face in business. I also remember telling him that I would have preferred to face that challenge down the road, not at 26 years old.”

“Looking back I have to say that experience taught me to never quit, as even the toughest obstacles can be overcome by persistence and determination and a positive attitude.”

Fast-forward to present day and Gorick Construction has completed many high-precision projects, including demolition work at a facility where precise scientific research work was ongoing. Lend Lease Construction called in Gorick Construction because of their ability to work in close proximity and not disturb structures nearby.

“We had a large project at Bristol Meyers Squib where we had to take a four-story building down that was attached to a building where there were scientists working, and we did that without any interruptions or issues for the client,” says Jim Mulherin, project executive at Lend Lease. “Al’s team had a lot to do with that. They are like surgeons with demolition. I would recommend them to anyone who had a demolition job that required expertise on the equipment, quality and safety.”

Diversification aids growth

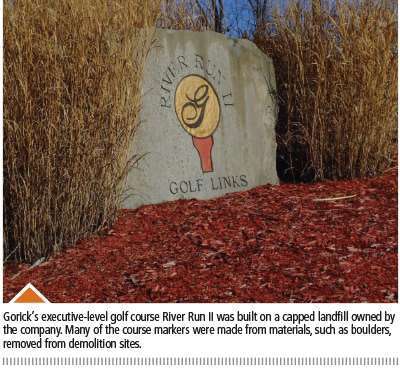

Gorick is extraordinarily practical and looks at ways of reusing materials, inspired the company’s ability to turn lemons into lemonade by converting the troubled landfill into an executive-level golf course.

River Run II Golf Links hosts many youth tournaments and corporate events, and is unique in that Gorick makes use of natural and recycled materials, such as trees and rocks, salvaged from other demo sites. The tee-box markers are boulders hauled in by his crew from a company gravel pit, trees are replanted to enhance landscaping and recycled granite is used for tee blocks.

Sports in general are top of mind for Gorick. He is a long-time youth hockey coach and his company has also expanded into sports facility work.

“I believe we are one of the most diverse companies around because of the wide diversity of work we tackle,” he says. “But our bread and butter has always been mass excavation and demolition.”

Demolition is such a cornerstone that Gorick served as a member of the board of directors of the National Demolition Association for six years. He feels his company is different from some national firms because they don’t travel all over the country for demolition work. This, he believes, helps his crews to strike a healthy work/life balance.

“In the past three to four years we’ve travelled up to 2 1/2 hours away,” he explains. “That’s far enough, but we could go farther. Most of my guys have family like myself and appreciate being home. I’m a believer that if your guys are happy and get to go home, you’ll get more out of them.”